design and manufacture grinding mills

2022-08-06T22:08:46+00:00

Grinding mills for mining and minerals processing

grinding mills are available at a low total cost of ownership due to low installation and operating costs, as well as simple maintenance We can help you determine the optimum setup for your needs to maximize the profitability of your operation Support from ’s grinding experts Every mining operation has a unique grinding process has experience of over 8,000 grinding mills globally, including manufacturing Our stateoftheart grinding process control solutions make it possible to stabilize, adjust, and improve your grinding results These enhancing technologies accompany our grinding mills and make the grinding process more efficient, which adds significant value to the whole concentration process These technologies include online particle size analyzers for the feed and discharge (Outotec RockSense and Outotec PSI® particle size analyzers), mill charge measurement Outotec Grinding Mills OutotecTable of ContentsTypes of Grinding Mill ManufacturedROD MILLSPEBBLE MILLSSelecting Wet or Dry Grinding MillHow much grinding power is neededSAG Mill vs Ball MillMill Grinding Mill Design Ball Mill Manufacturer

Manufacturer of Grinding Equipment Ultrafine Grinding Mill

When it comes to the research, development, design and manufacturing of a variety of powder grinding equipment, look no further than Dongguan Vsunny Machinery Co, Ltd, which was first established in 2012 Our product line is extensive, and with an expert research and development team, our equipment is widely used in the grinding of ultrafine powders of nonmetallic ores for later use in Based on the above optimized parameters, the precision grinding method assisted by laserinduced graphitization was used to manufacture a PCD micromill PCD was first subjected to laserinduced graphitization, and, after ultrasonic cleaning, the processed surface was treated with precision grinding The laserinduced graphitization equipment YLP1/100/20 (IPG Photonics) was Design, optimization and manufacturing of polycrystalline From design and manufacture to installation, commissioning and a comprehensive aftermarket service, Harcliff mills are designed with costeffectiveness in mind Fasttracked deliveries are undertaken when required Every mill design is accompanied by: Finite element modelling to Grinding Mills – Harcliff

design of a barite grinding mill in britain

Barite Grinding Mill is an ideal largescale grinding equipment a combination of grinding technology set of crushing drying grinding grading conveyor in one high production efficiency barite Grinding Mill can be widely used in cement power metallurgy chemical industry nonmetallic mineral industries Commonly used in fine grinding We are a professional mining machinery manufacturer, the main Ball mills are also used in pyrotechnics and the manufacture of black powder, thus causing no further grinding Ball mills are used extensively in the mechanical alloying process in which they are used for grinding and for cold welding, producing alloys from powders The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for Ball mill WikipediaStarkey Associates Inc is the name behind a number of the most successful grinding circuit designs in the mining industry today We are proud to offer grinding circuit designs that can achieve target throughput and grind from day oneStarkey Associates Inc Leaders in Comminution Design

Stirred Milling Technology – A New Concept in Fine Grinding

The vertical stirred media grinding mill uses a grinding chamber filled with small beads whereby comminution takes place by attrition between the beads The stirring effect is caused by rotating discs mounted on a shaft There are also stationary discs on the mill body positioned in between each rotational disc The mill structure and its main components are presented in Figure 1 191 The grinding mills we manufacture are superior in design and durability Our first class products are created for hasslefree operation We offer a diverse line of pulverizing equipment that is ideal for nearly every application All of our grinding mills are pretested for top levels of quality Our company has been creating top notch solutions since 1980 and we will continue to assist you Grinding Mill Manufacturers Suppliers IQS DirectoryLet us design and manufacture highperformance tooling products that meet your precise specifications Standard End Mills Custom Tool's standard end mills are perfect for your everyday cutting jobs With excellent tool strength, superior surface finish, and versatile cutting applications, our standard end mills will meet and exceed your needs Our standard end mills are built for your Standard End Mills Custom Tool Grinding

Grinding Mills 911Metallurgist

Therefore, grinding deserves the most scrutiny of all operations during the design procedure A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000 connected horsepower have been sold during the last twenty years Obviously, this type of grinding approach cannot be arbitrarily excluded from Grinding mill procurement timelines minimized and; Profits confidently realized; grinding production targets consistently met from startup We also provide outstanding process engineering services to develop customized grinding circuit designs in a timely manner Mining companies of all sizes who require fast project execution and accurate mill design results, have come to count on our proven Starkey Associates Inc Leaders in Comminution Design Nevertheless, a previously developed simulation program can be effectively used to facilitate the design and manufacture of the end mill, with proper selection of wheel geometry and wheel positions as output A program for the tool grinder was developed to simulate the grinding result and generate NC code as CAD/CAM system The end mill with varying rake and clearance Development of design and manufacturing technology for end

STMMicron Machines for dry grinding and selection Mills

STMMicron is at the cutting edge of design and manufacture of machines for dry grinding and selection Our milling machines and dynamic classifiers can process many types of product into powder or grains Our dry grinding technologies give excellent performance in terms of production and granulometric, testifying to the high quality of our machinery We supply machines in the following Barite Grinding Mill is an ideal largescale grinding equipment a combination of grinding technology set of crushing drying grinding grading conveyor in one high production efficiency barite Grinding Mill can be widely used in cement power metallurgy chemical industry nonmetallic mineral industries Commonly used in fine grinding We are a professional mining machinery manufacturer, the main design of a barite grinding mill in britainCB Mills was the original vertical mill manufacturer with our wellknown "Red Head" Mill that has served the dispersion and grinding industry for over 63 years Now, after over 39 years of horizontal milling experience, CB Mills is proud to introduce our own “American made”, costcompetitive, horizontal millCustom Steel Tanks, Media Mills, Liquid Processing Tanks

Prototype Design and Manufacturing Manual

capabilities, welding capabilities, heavy machining, precision grinding, waterjet cutting, EDM, rapid prototyping, etc) o Shop preferred manufacturing methods and materials o Machine tool (lathe, mill) capacity What is the largest or smallest size workpieces and cutting tools shop’s machines can comfortably the accommodate o Time line required to deliver parts • While in the design HARCLIFF MINING SERVICES’ comprehensive and continually expanding product and service offering includes the design, manufacture and refurbishment of grinding mills and associated components, the manufacture and refurbishment of open gearing and industrial gearboxes and the design and manufacture of rotary scrubbers We also produce kilns and dryer parts, manufacture wear parts Harcliff – Mining ServicesTherefore, grinding deserves the most scrutiny of all operations during the design procedure A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000 connected horsepower have been sold during the last twenty years Obviously, this type of grinding approach cannot be arbitrarily excluded from Grinding Mills 911Metallurgist

Machines Drake Mfg

Rough mill parts for finish grinding View Machines Rack Mills High speed rack milling View Machines BUILT FOR EXCELLENCE Drake Manufacturing has revolutionized the thread grinding industry with precision built solutions engineered for your success Our capabilities allow us to design and manufacture stateofthe art thread grinders for industries including Aerospace, Automotive, This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL MILL STMMicron is at the cutting edge of design and manufacture of machines for dry grinding and selection Our milling machines and dynamic classifiers can process many types of product into powder or grains Our dry grinding technologies give excellent performance in terms of production and granulometric, testifying to the high quality of our machinery We supply machines in the following STMMicron Machines for dry grinding and selection Mills

Basket Mill Design and Manufacture in India

Basket Mill(Hydraulic Lifting) is a wet grinding machine applicable for middle and low viscosity fluids and batch type production equipment Through alldirection strong momentum generated by irregular collision between the grinding beads, the particle size of the materials becomes smallerlt is suitable for coatings, inks, pigments, colorants, pesticides, cosmetics and other industries with SAG is an acronym for semiautogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21% The largest SAG mill is 42' (128m) in diameter, powered by a 28 MW (38,000 HP) motor Ball Mill Design/Power Calculation Moredesign of machine foundation for grinding millclay grinding mill european manufacturers in guam raymond mill raymond mill china raymond mill MTW Series Trapezium Mill 60045μm MTW Raymond Mill MTW Series European Trapezium Grinding Mill MTW Raymond Mill is developed on the basis of our experts longterm R D experience structure performance analyses of traditional grinding mills and the manufacture of traditional grinding mill in guam

Mills Liners – FFF Australia

Our Milling and Grinding product group brings both the grinding media and mill liners into one holistic focused area of expertise and excellence FFF has been appointed the Australian sales support representative by international partners who specialise in the design, manufacture and supply of quality SAG, AG, ROD and BALL Mill components liners Forged mill ball heat treatment Mill ball Grinding Mill Design Morgardshammar started to design and deliver grinding mills in the beginning of the century Today the mills are computer designed and manufactured in big plants with modern machinery In order to keep manufacturing costs at a minimum level Morgardshammar has a series of standard mill diameters up to and including 65 mgrinding mill machine manufacturers singaporeHammer mills are recognized as technology capable of finely grinding the greatest variety of materials [3,13] and are noted for achieving high sizereduction ratios and yielding cubicshaped particles [14,15] Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil ity [16] Fine Optimizing hammer mill performance through screen

- chemicalposition of limestone ncrete crushing plant

- transformer oil rollers

- modular of mobile crushing processing plants russia

- used ncrete pump for sale

- juggling 5 ball mills mess

- how to buy a mini rock crusher stone crusher machine

- mesh ball mill micro mill in africa

- PY SPIRING CONE CRUSHER

- quarry use DXN ne crusher

- gyratory crusher diameter

- atta chakki crusher machine price list

- manufacturing artificial sand in India

- boll mill manufacturers in gujarat

- crushing machine china jaw crusher

- china jiecahng stone mobile crushing plant

- crusher plant manufacturer in russia

- gypsum block production line in west germany

- power requirement for 200 150 tph crushing plant

- MOBILE LINEAR MINERAL CRUSHER

- used small crusher stone plant machinery

- what is the principle of hammer crusher

- SILICA SAND INDIAGRINDING MILL

- large clay plant pots to buy

- ball ball milling grinding milling equipment for sale

- Sound Measuring System In Coal Mill

- 10tph gold ore processing plant

- raymond grinding mill raymond mill

- biggest stone crusher plant in germany

- details of ne crusher

- small scale mining stamp mill price in zimbabwe

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

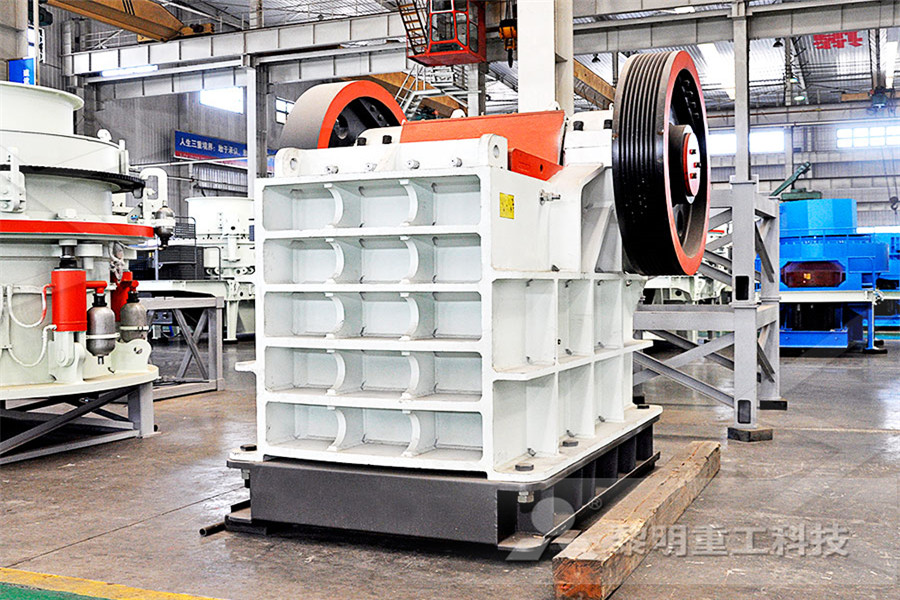

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine