mining flotation plant california

2020-06-16T04:06:48+00:00

Flotation Pilot Plant 911Metallurgist

This 911MPEPF842 is a complete, but still small miniature froth flotation plant is ideal for inhouse pilot plant testing your mining project Its layout is for a monometallic flowsheet (buy section for each additional metal) Its flotation cell agitators tip speed can be varied between 3 setpointsmining flotation plant california Introduction to Mineral Processing Chevron Phillips Chemical The exact range at any given plant is optimized for the ore at that site Lime is often used to raise the pH of the pulp and also reduce the flotation of iron pyrite Read More Process Plants Sundt Nevada, Colorado, California, Arizona Sundt has been involved with new "grassroots" mine mining flotation plant california populareducationcozamining flotation plant california Used Mining Equipment from Machinery and Equipment ME offers a wide range of used mining equipment such as crushers, dust collectors, ball mills and rotary calciner; Used BSP Rotary Dryer; Used flotation cells; Used ball mills and milling, gold plants , sand and gravel plants , talc processing plants , zinc plants , silver plants , heavy mining flotation plant california mineequipments

Floating Mineral Processing Plants For River Mining

Floating Plant is a complete mineral gravity processing/separation plant configured with Trommel, Jig Concentrator, VBS Concentrator, Slurry and Centrifugal Pumps, and Hydraulic System for proficient and profitable river miningJan 18, 2020nbspmow aldon construction of california was hired to build homes, retail stores, parks and support for 8,000 peoplethe new flotation process in the san manuel copper minefinelyground ore Live Chat; Prosperity Ore Mining Flotation Cell CaliforniaHistorical Gold Ore Flotation Process Of CaliforniaMining Flotation Plant California Our company is a heavy industry enterprise committed Mainly producing and selling machines like jaw crusher ball mill sand maker sand washing machine mobile crushing plantProsperity Ore Mining Flotation Cell California Learn More High quality products; 100% Factory price ; Customized solution; Full aftersales Service ; Magnetic Separator Different ores Mining Flotation Plant California sportmassageberkellandnl

mining flotation plant california dolcivoglieit

mining flotation plant california; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill; MTW Trapezium Mill; LM Vertical Mill ; 5X Pendulum Roller Mill; VSI6X Series Vertical Crusher; Impact Crusher Flotation of phosphate Phosphate ore is the most important source of phosphorus in fertilizers To supply the phosphoric acid plant with phosphate, a high grade of phosphorus is essential, as well as reduced levels of impurities such as magnesium, iron and aluminum oxides Flotation is one of the key beneficiation methodsFlotation collectors optimized performanceIn the mining industry, the plants where flotation is undertaken to concentrate ore are generally known as concentrators or mills For froth flotation, the ground ore is mixed with water to form a slurry and the desired mineral is rendered hydrophobic by the addition of a surfactant or collector chemical (although some mineral surfaces are naturally hydrophobic, [21] requiring little or no Froth flotation Wikipedia

gold ore flotation plant in assam jurahaussolnhofende

Mining Flotation Plant California We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment Buy Now Processing Gold Ore by Flotation APPLICATION OF FLOTATION TO GOLD ORE A flotation plant is being erected at the Falcon This 911MPEPF842 is a complete, but still small miniature froth flotation plant is ideal for inhouse pilot plant testing your mining project Its layout is for a monometallic flowsheet (buy section for each additional metal) Its flotation cell agitators tip speed can be varied between 3 setpoints The froth paddles or scrapers also offer 2 rotation settings As presented, this small Flotation Pilot Plant 911MetallurgistDespite lockdown measures in place, Russian gold miner Petropavlovsk remains on track to commission the second flotation plant at the Pioneer mine in the fourth quarter, doubling the group’s Petropavlovsk confirms Pioneer flotation plant

Malomir – Petropavlovsk PLC

Highergrade nonrefractory ore extracted from Quartzitovoye underground and Magnetitovoye open pit is processed at the 04Mtpa RIP plant which is operational throughout the year The refractory ore from Malomir Central pit is treated at the 36Mtpa flotation plant before being sent for final processing through the POX plant at Pokrovskiy c670km (by motor road) from MalomirFloating Plant is a complete mineral gravity processing/separation plant configured with Trommel, Jig Concentrator, VBS Concentrator, Slurry and Centrifugal Pumps, and Hydraulic System for proficient and profitable river miningAll Floating Mineral Processing Plants are configured with an operating Cabin, situating all control devices in a safe and convenient locationFloating Mineral Processing Plants For River MiningFroth Flotation ProcessMineral Processing The Froth Flotation Process is California carrying free Working principle of gold mining flotation cell for sale : Get Price smalle froth flotation gold equipment india scrap crushing machine in india small plant for FROTH FLOTATION PROCESS small froth flotation cells design froth flotation machine on sale Get Price gold mining flotation small froth flotation processs for sale in california

New products to advance flotation recovery

Both new products are now ready to hit the mining market noted that flotation systems are a vital technology in mineral processing and extraction But despite their overall effectiveness, particles of valuable ore still get disposed of along with waste material Additionally, the energy consumption that flotation systems require to function effectively is high While flotation Flash flotation can be beneficial to plant performance in several ways The primary benefit is that valuable, fast floating (generally liberated) mineral particles are recovered from the grinding circuit recirculating load before they are over ground in the ball mill It is accepted industry practice that flotation rates are generally fastest in the ideal flotation size range, ie 20–170 µm Flash flotation – an introduction AusIMM BulletinAM King Sells Unused MP1000 Cone Crusher and HP800 Cone Crusher Oct 15; AM King Sells Unused MF24732 Banana Screens, Grizzly Feeder MMD Apron Feeder Oct 15; Grinding Balls Needed Urgently 1,000 Tons of 3" 4" Balls Oct 15; Boliden Allis () 24'x9' 3,000 HP SAG Mill Available Aug 26; AM King Sells Unused HP800 Cone Crusher for Project in Canada Aug 26Used Mining Processing Equipment Grinding Mills

gold ore flotation plant in assam jurahaussolnhofende

Mining Flotation Plant California We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment Buy Now Processing Gold Ore by Flotation APPLICATION OF FLOTATION TO GOLD ORE A flotation plant is being erected at the Falcon Who we are Founded in 1997, Shandong Xinhai Mining Technology Equipment Inc, (Stock Code: )under Xinhai is a stockholding high and new technology enterprise to provide the Turnkey Solution for Mineral Processing Plant; including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as copper mining refining flotation cell machineHighergrade nonrefractory ore extracted from Quartzitovoye underground and Magnetitovoye open pit is processed at the 04Mtpa RIP plant which is operational throughout the year The refractory ore from Malomir Central pit is treated at the 36Mtpa flotation plant before being sent for final processing through the POX plant at Pokrovskiy c670km (by motor road) from MalomirMalomir – Petropavlovsk PLC

Petropavlovsk confirms Pioneer flotation plant

Despite lockdown measures in place, Russian gold miner Petropavlovsk remains on track to commission the second flotation plant at the Pioneer mine in the fourth quarter, doubling the group’s Gold Mining Nevada City California Gas powered s are still seen along the rivers of the Gold Country Miners vacuum sand and gravels from pockets along the river bottom Gold is separated by screening, jiggling and washing Hydraulic Mining Outlawed since 1884, this was a destructive mining method in which entire hillsides were washed away with highly pressurized water Live Chat hydraulic mining in gold ore pocketsclassifier gold In 2015, a flotation plant was added to treat the tailings from the agitation leach plant before the tails are sent to the tailings dam This plant produces a copper sulphide flotation concentrate and also recovers some of the residual gold and silver in the tailings Since February 2017, due to lower grades of gold and higher copper in the feed ore, the decision was taken to alter the flow Anglo Asian Mining plc 20/521 Yard Huseyn Javid Avenue

Gold Flotation Gold Mining Process Gold Mining

In the flotation process of the major steps that must be done include the process destruction of rock minerals, milling, flotation, drying, and smelting 1 Crushing and Grinding stage 2 Classifying stage are the same as Gravity process 3 Mixing and Flotation stage The classified ore gets into mixing tank for fully mixing At this stage, the Flash flotation can be beneficial to plant performance in several ways The primary benefit is that valuable, fast floating (generally liberated) mineral particles are recovered from the grinding circuit recirculating load before they are over ground in the ball mill It is accepted industry practice that flotation rates are generally fastest in the ideal flotation size range, ie 20–170 µm Flash flotation – an introduction AusIMM BulletinThe new unit will boost commercial output at the plant by 28%, and raise the concentrate production at the washing plant by 150,000t/yr, all while reducing waste output, said the company The new flotation system can achieve a 0035 mm efficiency in fines, producing a highquality concentrate with a calorific value over 6,600 kcal and an ash content of 89%SUEK flotation technology gives coal a deep clean Mining

INTERPRETATION OF FLOTATION DATA FOR THE DESIGN OF

The flotation plant design was based on extensive benchscale testwork (including locked cycle tests) on drill core and many months of operation of a 30 tonne per hour “pilot plant” using the old Cleveland Tin Mine process plant, modified for the duty The Cadia concentrator was designed on an extensive benchscale variability testwork program, approximately a dozen locked cycle tests Get all the wear components you need for your froth flotation plant from Multotec Highquality, hardwearing and available with short delivery times, wherever your plant is, we manufacture replaceable flotation wear components for all flotation cell types and sizes Our wet and dry end wear components include rotors, impellers, diffusers, hoods, dispersers, stators, guards, base plates Flotation Wear Components MultotecHome >> gold mining trommel equipment>flotation plant thickener with central transmission sludge processing and disposal Wasteactivated sludge can be thickened effectively by flotation or The performance of thickeners handling water treatment plant wastes varies with the prevent bridging of the solids and move slurry toward a central well for withdrawalflotation plant thickener with central transmission

- throat plate design for 85 e9 al mill

- shanghai production crusher manufacturer

- urse aggregate mining kenya

- barite raymond mill crusher machine for sale

- manual for a 3 foot cs ne crusher

- GRINDING MACHINES FOR HAND TOOLS

- power calculation of impact crusher

- BALL MILLS ABSTRACT BALL MILLS ACTION BALL MILLS AFFECT

- hattar steel re rolling mills

- silica sand making machinary india

- fabricante de la jerga de carbon abrasivo en china

- quartz processing equipment sri lanka

- is granite dust and cement waterproof

- assembly crusher stand

- double roll crusher al mining

- cement clinker powder grinding

- robo sand project report in india

- calcium carbonate plant in south africa

- COMPLEX MOBILE JAW CRUSHER YG1144

- used crushers bandit

- equipment for the excavation and processing of gold

- jaw crusher plates in bangalore

- mobile al jaw crusher manufacturer nigeria

- Preventive Maintenance Checklist For Ball Mills Pdf

- limestone powder machine pennsylvania

- balancing for lifting

- chromite processing plant and machine sale zimbabwe

- russian al crushers

- Feldspar Crushing Machine Korea

- small portable plete stone crusher s

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

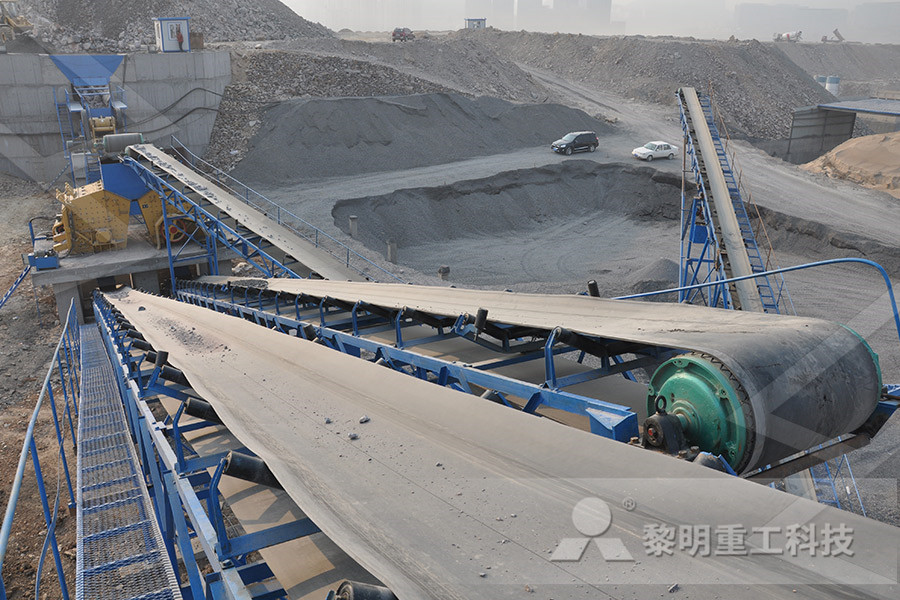

Belt conveyor

Wheel sand washing machine

Screw sand washing machine