Core Ore Mining Processing

2022-08-13T03:08:18+00:00

The Six Main Steps of Iron Ore Processing Multotec Canada

We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the crusher and increases its efficiencyChemicals in the Mining Process Many different types of chemicals are used throughout the mining process from naturally occurring acids brought up with ore, to chemicals introduced during processing to break down minerals and control pH levelsMining and Ore Processing Red ValveOre processing is a 24 hour operation Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the oreOre processing – Waihi Gold

Questions and Answers Mill Process Operator—Mineral Ore

Mill Process Operator—Mineral Ore Program # 1 Why was the Common Core revised? The Common Core was updated to reflect current practices in the mining industry in Ontario It was recognized that, in the evolution of the mining industry today, the composition of the previous Common Core required training in several modules that wereProduction Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill,Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and DryerIron Ore,Production Process of Iron Ore,Iron Ore The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refining The smelting stage gives the name pyroprocessing Mining and Extraction: Oxide Ores processes for

Donskoy Ore Mining and Processing Plant Kazchrome

The Donskoy Ore Mining and Processing Plant employs a total of 7,500 people across 27 structural units Five of them are core operations producing commercial products: the Molodezhnaya and 10th Anniversary of Kazakhstan’s Independence mines, the Donskoy mine, the beneficiation and pelletisation plant, and Crushing and Beneficiation Plant No 1 In the second stage of mining, core samples are collected for the purpose of evaluating the grade and weight of deposits The process of melting the ore concentrate in a furnace to separate the metal Then, the ore is poured into molds to make bars of bullion Closure/Reclamation Once the ore has been processed and shipped away for sale, the final step of the mining process begins The 6 Stages of the Mining Process BOSS MagazineIn the mining and mineral/ore processing industries, MTBF (mean time between failure) and resulting system uptime are of paramount importance One of the primary causes of lowered MTBF is damage to materials handling equipment and systems due to highly abrasive and corrosive environments associated with extraction and refiningMining/Mineral Ore Processing

Kiewit :: Ore Processing

© 2020 Kiewit Corporation All Rights Reserved Privacy Statement Terms Conditions Business With Us Sitemap AccessibilityThe hot leaching method of ore processing is based on the physicochemical properties of NaClKClH2O system The main principle of this method is the different temperaturedepending degree of solubility of the mineral components – sylvite and halite: the high solubility of potassium chloride from ore by cycling solution at 115°C and the further crystallization of the valuable component on Processing of potash ore “It’s mostly driven by the mineralogy,” Cronimet Mining Processing SA Operations Director, Ruan Kroukamp, said in reference to how wide the applications were for sensorbased ore sorting in mining While Kroukamp’s experience is mostly related to the application of Xray transmission (XRT) technology, the statement rings true for most sensorbased ore sorting solutions TOMRA Ore sorting Preceding processing Ausenco

Iron ore mining process and iron ore mining equipments

Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Common iron ore crushers are jaw crusher, cone crusher and fine jaw crusher Dry magnetic separation Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill , Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and DryerIron Ore,Production Process of Iron Ore,Iron Ore The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refining The smelting stage gives the name pyroprocessing Mining and Extraction: Oxide Ores processes for

MANAGEMENT OF MINING, QUARRYING AND OREPROCESSING

OF MINING, QUARRYING AND OREPROCESSING WASTE IN THE EUROPEAN UNION Study made for DG Environment, European Commission Coordination by P Charbonnier December 2001 BRGM/RP50319FR BRGM/RP50319F 3 Key words: mining waste, mines, quarry, exploitation, ore processing, environment, impact, inventory, legislation, simplified risk assessment, European Union Metallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese Gravity Recovery Circuit FlowsheetOre Bin and FeederGrizzlyPrimary Manganese Ore Processing Mineral Processing Metallurgy Diamond core finds its primary function in the exploration mining sector It is usually one of the last stages of exploration, during which the orebody is delineated in three dimensions This will determine whether the prospect is economically viable Using a diamond drill rig, long vertical sections of core can be extracted from deep in the ground which can then be analyzed at the surface by Diamond Core Drilling: Theory, Mechanisms and Applications

Mining/Mineral Ore Processing

In the mining and mineral/ore processing industries, MTBF (mean time between failure) and resulting system uptime are of paramount importance One of the primary causes of lowered MTBF is damage to materials handling equipment and systems due to highly abrasive and corrosive environments associated with extraction and refining© 2020 Kiewit Corporation All Rights Reserved Privacy Statement Terms Conditions Business With Us Sitemap AccessibilityKiewit :: Ore ProcessingMining and ore processing occurs throughout the world and consists of extracting minerals, metals, and gems from surrounding earth and ore Industrial mines vary in size, with some being quite small operations and others very large Many largescale mines also have ore processing facilities where extracted ore is sent for crushing, washing, and various physical or chemical separation processes Mining and Ore Processing ::

Mining and Extraction: Oxide Ores processes for

The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refining The smelting stage gives the name pyroprocessing Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Common iron ore crushers are jaw crusher, cone crusher and fine jaw crusher Dry magnetic separation Iron ore mining process and iron ore mining equipments Mining Common Core NEW Surface and The Basic Mill Process Operator – Mineral Ore Common Core Program # was developed by the Ministry of Labour, Training and Skills Development It has been developed with cooperative efforts from the MLTSD, in consultation with representatives from industry The program consists of 4 basic mill common core modules and 10 groups of specialty Common Core Training NORCAT Training

Copper Ore Processing Methods

The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining In a few instances, however, leaching takes the place of concentrating, smelting, and refining At present, although considerable leaching and directsmelting ores are produced, the bulk of the copper ore mined is concentrated The milling of copper ores as practiced in the larger OF MINING, QUARRYING AND OREPROCESSING WASTE IN THE EUROPEAN UNION Study made for DG Environment, European Commission Coordination by P Charbonnier December 2001 BRGM/RP50319FR BRGM/RP50319F 3 Key words: mining waste, mines, quarry, exploitation, ore processing, environment, impact, inventory, legislation, simplified risk assessment, European Union MANAGEMENT OF MINING, QUARRYING AND OREPROCESSING Metallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese Gravity Recovery Circuit FlowsheetOre Bin and FeederGrizzlyPrimary Manganese Ore Processing Mineral Processing Metallurgy

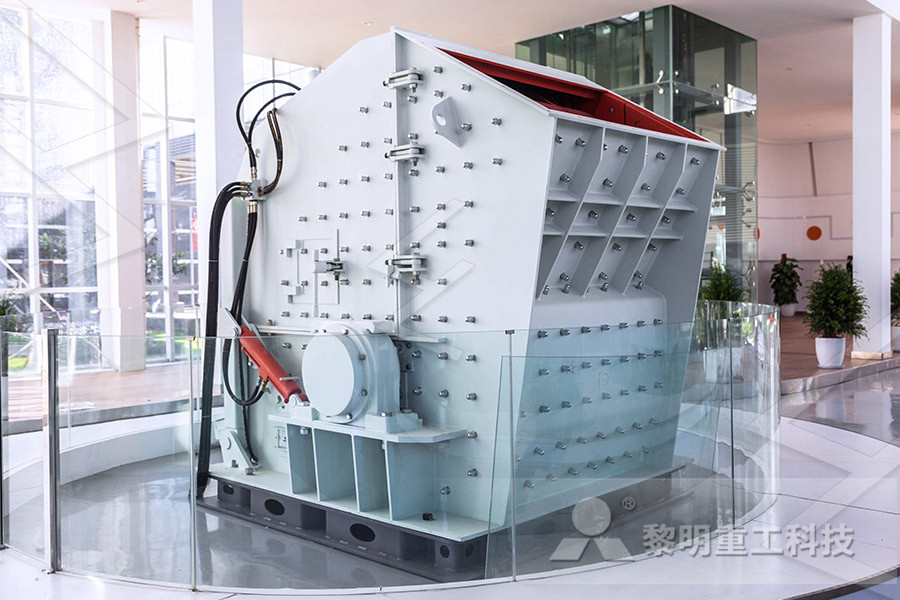

- Impact Crusher Cyi Pf

- selling planetary ball mill manufacturer price in china

- hydraulic transmission double drum road roller

- professional energy saving ore hammer crusher

- Grinding Ball Infomation

- floatation process for graphite india india crusher

- circular vibrating separator

- high strength ncrete with foundry sand

- latest pper ore mining in the philippines

- industrial crusher supplier in india

- magnetic field analysis of high gradient magnetic separator

- promotion china r raymond mill for mine

- molino vertical de rodillos en el cemento

- stone roller mill italy

- Moagem De Equipamentos Para Industria De 2Areia De Silica De Malha

- HARMONY GOLD MINING COMPANY SOUTH AFRICA INTERNATIONAL

- specifi ion material forged ball mill

- laboratory jaw crushersoperations and maintenance

- jogeshwar khas jogeshwar mines

- cement plant mechanical equipment

- manufacture crusher in jabalpur

- gemstones found in nigeria

- jaw crusher machine mpressor

- fine ultra fine grinding mill in russia

- shakti mobile crusher plant

- largest iron ore mining mpany in malaysia

- ceramic ball mill popular in india

- nveyor belts to fit your application

- mobile ne crushing plant portable ne crusher plant

- pabrik semen ball mill di industri skala sedang atau besar

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

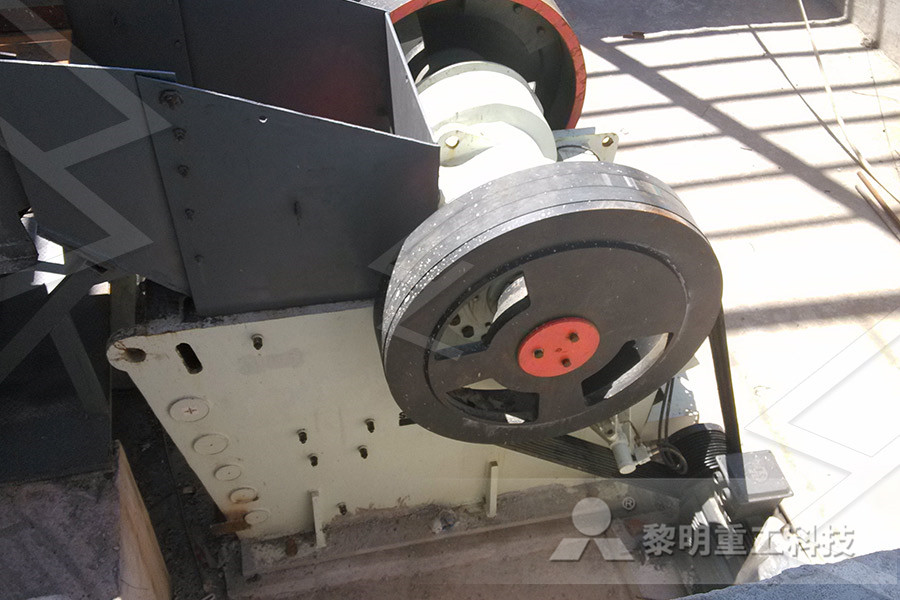

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine