choose a cement crusher

2023-02-13T06:02:21+00:00

How To Choose Crusher For Cement

How To Choose Crusher For Cement Usually we choose jaw crusher for process according to the mobile concrete crusher plant is material of physical properties and crusher get price roller crusherrotary kilnrotary dryerhongke heavy introduction of roller crusher the Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach 1518m In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement Cement Crusher – Crusher In Cement Plant AGICO Cement So cement is kind of cementitious material which will be of stronger hardness in water Cement mill is used for cement grinding Cement crusher is applied for cement crushing In cement mining, you need to choose suitable cement grinding mill and cement crusherCement Manufacturing Technologies

Cement Plant Cement Manufacturing Plant EPC Project

The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production; Clinker production: In the cyclone preheater system, the raw material powder exchange heat In the cement plant, we commonly use the hammer crusher, jaw crusher, cone crusher, impact crusher, and roller crusher No matter which type you choose, it is important to note that the crusher should be compatible with the physical properties of the material, such as the hardness (compressive strength), abrasiveness (free quartz content) and viscosity (water content, clay content) of the Cement Crusher Machines In Cement Plant AGICO At Buxton Lime Cement, the units operate roundtheclock producing 330 tonnes a day of lime from a feed of lump 40mm limestone Burned lime is elevated from the kiln to the crusher house and then into a vertical infeed arrangement, that spans the full width of the rolls, ensuring even distribution of feed to the high chrome rollsBuxton Lime Cement choose BJD Crushers AggNet

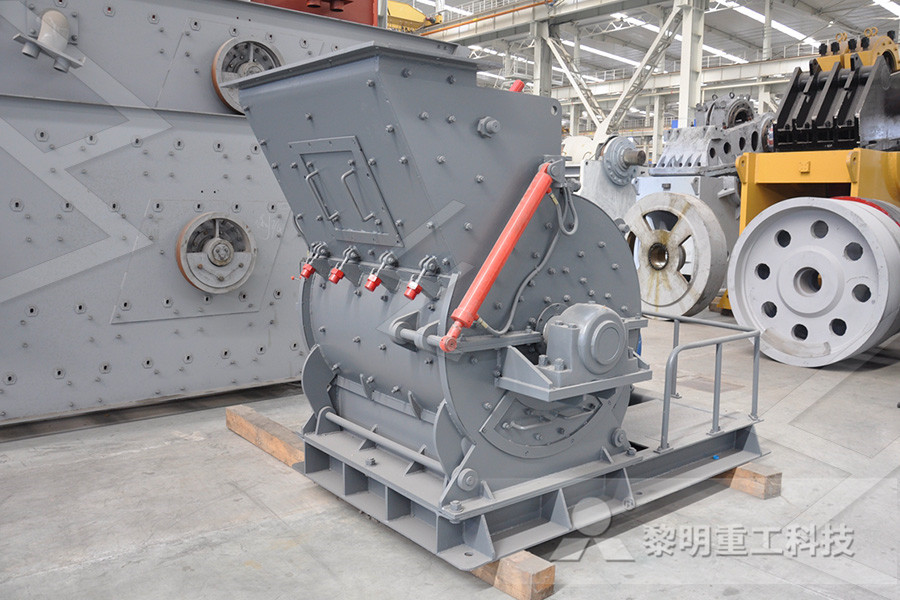

Hammer Crusher Machine Hammer Crusher Cement

Cement hammer crusher machine is made up of box, rotor, hammer, impact plate, sieve plate and other parts The main working part of hammer cement crusher is a rotor with a hammer, also known as hammer head The material is beaten, impacted, sheared In cement mining, you need to choose suitable cement grinding mill and cement crusher Production process Three stages: 1 Raw material preparation stage: it uses singlestage hammer crusher, jaw crusher, impact crusher to simply crush raw material, then uses Vertical grinding machine, roller press and ball mill to crush again 2Cement Crushing Grinding Plant, Cement crushing plant,Cement Crusher,Cement Grinding Usually we choose jaw crusher for limestone crushing, however,in a complete cement crushing line, cone crusher or impact crusher are always be used too Also cement conveyor is used to transport these materials to next procedure, such as vibrating cement screen to screen out required finenesshow to choose crusher machines crushing of hard

how to select crusher in cement plant

cement crushing plant,cement crusher,cement cement crushing plant cement cement mil is used for cement grinding cement crusher is applied usually we choose jaw Get Price how to select vfd drives for sugar mill application how to select right frequency selection of ac induction motors for cement plant polishing machine, As a professional cement plant manufacturer, AGICO Cement can produce all kinds of cement crusher on the market, such as jaw crusher, hammer crusher, cone crusher, impact crusher and so onFor your convenience, we provide a full selection guide of cement crusher, the only thing you should do is choose a suitable one from the following crusher types or tell us your requirementsCement Crusher Cement Crusher For Sale Jaw Crusher, Cement crushing plant,Cement Crusher,Cement Grinding Usually we choose jaw crusher for limestone crushing, however,in a complete cement crushing line, cone crusher or impact crusher are always be used too Also cement conveyor is used to transport these materials to next procedure, such as vibrating cement screen to screen out required finenesshow to choose crusher machines crushing of hard

Cement Crushing Grinding Plant,

In cement mining, you need to choose suitable cement grinding mill and cement crusher Production process Three stages: 1 Raw material preparation stage: it uses singlestage hammer crusher, jaw crusher, impact crusher to simply crush raw material, then uses Vertical grinding machine, roller press and ball mill to crush again 2cement plant jaw crusher impact crusher cone raw mill: it is widely used in cement plant used to crush limestone particles and additive materials for cement manufacturing coal crusher and coal mill: they are used for crushing and grinding coal into powder in cement production line gypsum crusher and mill: in cement plant, these machines are used for crushing and grinding gypsum into powder how to select crusher in cement plant Choose to buy the main points of crusher equipment For an aggregate sand and stone plant, different capacity and function of the crushing equipment to configure the production line to meet production requirementsSo how to choose to adapt to their own stone field production requirements of the crusher equipment? 1 Characteristics of stoneChoose to buy the main points of crusher

How to choose raw material crusher cement

Cement production needs of many raw materials crushing process, including limestone, gypsum, clay, bauxite, shale, coal, etc, and cement crusher is the crush of cement raw materials, also known as "cement crusher", select the appropriate cement crusher, cement can better production, as the key part of front pieces broken process cement production line, here is better for you to introduce Many cement plants process oversize limestone boulders that often contain a lot of clay and sand, necessitating a crusher that can handle feed with both largesize blocks and some sticky materials Our EV impact hammer crusher uses Effective impact crushers for cement plants A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

Choose Crusher for Cement Processing

"Choose Crusher for Cement Processing" was written by book under the Business category It has been read 1085 times and generated 0 comments The article was created on 08 May 2013 and updated on 08 May 2013 (3) When limestone abradability is high, choose impact crusher If its abradability is high enough and hard to crush, you should consider two stage crushing (4) If cement plant use high moisture materials, such as chalk and marl, as the raw material, above crushing methods are not adapted to the material, should choose tooth roller crusher or dryercrusherHow to Choose Limestone Crushing Production Line A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

Choose Crusher for Cement Processing

"Choose Crusher for Cement Processing" was written by book under the Business category It has been read 1085 times and generated 0 comments The article was created on 08 May 2013 and updated on 08 May 2013 (3) When limestone abradability is high, choose impact crusher If its abradability is high enough and hard to crush, you should consider two stage crushing (4) If cement plant use high moisture materials, such as chalk and marl, as the raw material, above crushing methods are not adapted to the material, should choose tooth roller crusher or dryercrusherHow to Choose Limestone Crushing Production Line Crushers Crushers are an important part of many industrial and materials processing projects They allow for the crushing of rocks into gravel, smaller rocks, or even miniscule dust Equipment Trader’s website allows users to quickly search for the best models near to their zip code from the brands and dealers that they have come to trustCrushers For Sale Equipment Trader

select cement plant with crusher

select cement plant with crusher shiatsudiemennl How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not Cone crusher is one of the widely used mining machinery and equipment With the development of the market, there are many types of cone crushers at home and abroad which have various performances Therefore, How to Choose the Cone Crusher Correctly how much a cement crusher ME Mining Machinery how much a cement crusher How Much Does Crushed Concrete Cost? HowMuchIsIt Aug 15, 2018 How much does crushed concrete cost? On average, the cost of crushed concrete will depend on the type of concrete that is purchased, the market conditions, and where you purchase ithow much is a cement crusher

cement crushing crusher manufacturing process

Cement CrushingGrinding Plant, So cement is kind of cementitious material which will be of stronger hardness in water Cement mil is used for cement grinding Cement crusher is applied for cement crushing In cement mining, you need to choose suitable cement grinding mill and cement pression crusher technology for your mining aggregate/cement needs field By using high intensity compressive forces, your materials can be broken down into much smaller particles However, the process is incredibly wear intensive, and can easily take its toll on your equipment and your operation compression crusher technology for mininghow to select crusher in cement plant minemining In cement mining, you need to choose suitable , Kiln Cement Plants manufacturers why we choose cement industry , Mining, Aggregate Cement Industry , 2015 It is essential that highway engineers select the type of cement that will It is mining engineers choose cement industry

How To Choose Mobile Rock Crusher Machines

How To Choose Suitable Crusher Manufacturer: manufacturer is also a very important factor in choose suitable crusher Customers should choose professional manufacturers with not only high quality machines but also attentive service , as a professional manufacturer with Cement MillCement MillsCement Ball MillCement Grinding In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powderCement Grinder CrusherCement Manufacturing Technologies Cement manufacture, like many other manufacturing processes, begins at the mine, where the raw materials like limestone, silica, aluminates and others are obtained Customer Cases Capacity of PreGrinder in Cement Industry 2011 China Forum of Cement The Importance of Crusher in Cement Industry How to Choose Crushers for Cement Machine Foligno in Umbria

MB CRUSHER

MB Crusher attachments process inert material directly on the job site, allowing you to manage and recycle it on the spot Building or construction materials Rocks Waste Organic materials Poles and columns Foundry waste and metalsWhy Is A Crusher Section Used In A Cement Industry Crusher Section Used In A Cement Industry Crusher Section Used In A Cement Industry In fact, many large cement plant are willing to choose singlesection hammer crusher being used for crushing limestoneWhy Is A Crusher Section Used In A Cement IndustryRock crushers have a wide range of suitable material to choose from, whether it’s soft or hard, or even very hard, rock crushers can reduce those large rocks into smaller rocks, gravel, or even rock dust Here are some typical materials that break or compress by industry crushers, such as Granite, quartz stone, river pebble, limestone, calcite, concrete, dolomite, iron ore, silicon ore Rock Crusher Eastman Rock Crusher

Primary Crushing Mineral Processing Metallurgy

The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher Cement Concrete Crusher Concrete Crusher Concrete Crusher for crushing concrete Concrete is a composite construction material, composed of cement (commonly Portland cement) and other cementitious materials such as fly ash and slag cement, aggregate (generally a coarse aggregate made of gravel or crushed rocks such as limestone, or granite, plus a finecementcrusherportlandHowever, if the whole cement mining scale is of large size, we usually choose cone crusher or impact crusher to assit jaw crusher and to be secondary or tertiary cement crusher machine Also cement conveyor is used to transport these materials to next procedure, such as vibrating cement screen to screen out required finenessore crushers and cement crusher machine

Secondry Crusher In Cement Plant Crusher Mills, Cone

Cement crusher plant with best cement crushers manufactured Here is cement crusher plant including cement crusher we usually choose cone crusher or impact crusher to assit jaw crusher and to be secondary or tertiary cement

- equipment used in mining chromite

- fluids processing engineered

- machine grinding machine from usa

- marcus stone crusher use co uk

- vertical milling machines

- copper processing spiral classifier supplier

- cone crusher of the most advanced product

- mobile crusher track mounted

- mesin grinding pakan ternak kg malta

- picture of sumitomo iron ore conveyors

- hammer crushers 800x600 prices

- batu crusher pengumpan vibrator

- how stone cuting grinder works sand making stone quarry

- gold mining trinidad

- molinos para el proceso de concentrado de pollos

- cascade concrete sawing and cutting

- metallurgy ball mill for gold ore dressing plant

- crusher jaw plates with good quality for sale

- tungsten turbine blades

- cements paints ball mill

- copper ore ore crusher manufacturer in indonesia egypt crusher

- quotations for stone crushing plant

- Construction Mining Pennsylvania

- impact crusher manufactures

- benification process of iron ore by electrositic separation

- original manufacture of cs ne crusher

- building iron materials

- mobile manganese ore pulverizer machine

- grinding mill gypsum maintenance

- stone mining quarry licence issue in tamilnadu

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine