vibrating screens requirements

2023-10-12T23:10:55+00:00

Vibrating Screen Types Working Principle [How To Choose

According to the type of materials and the requirements of users, the high manganese steel woven screen, punched screen plate and rubber screen plate can be used The circular vibrating screen is installed in the seat type The adjustment of the screen surface angle can be realized by changing the position and height of the spring supportHighfrequency vibrating screens are usually operated at an angle of inclination, traditionally varying between 0 and 25 degrees, up to 45 degrees In addition, it should operate at a low stroke with a frequency range of 15007200 RPMVibrating Screen Mineral ProcessingUsing empirical values of the materials obtained through lab tests, the vibrating screen is designed according to the features and requirements of the product to be processed The study of the particle, its composition, its shape and hardness is also very important Other important factors are:Vibrating screens Vibroprocess

Dillion Screen Features Vibrating Screens

Unique design and construction makes maintenance and parts replacement simple When the longwearing screen cloth must be changed, access ports in the sides of the screen body simplify the job Vibrating mechanism can be removed from either side of the screen body Mechanism is lubricated through grease pipes outside the screen bodyMultotec customises vibrating screen centrifuges according to your unique requirements, and also stocks a range of standard vibrating screen centrifuges Models: HSG 600, HSG 800, HSG 1 100, HSG 1 200, HSG 1 200, HSG 1 300, HSG 1 400 HSG 1 650 ; Vibrating Screen Centrifuge MultotecVibramech vibrating screens are custom designed for client needs and cover a vast range of sizes and unique process applications Our screen design makes use of Finite Element Method and Strain Gauge Analysis to prove structural integrityVibrating Screens Vibramech

Vibrating Screens Vibrating Screen Vibra Screw

Vibra Screw provides a wide variety of highly efficient vibrating screens for applications that require coarse scalping, multideck separation, or dewatering Each vibrating screen can be fitted with standard market grade or tensile bolting cloth, stainless steel According to the type of materials and the requirements of users, the high manganese steel woven screen, punched screen plate and rubber screen plate can be used The circular vibrating screen is installed in the seat type The adjustment of the screen surface angle can be realized by changing the position and height of the spring supportVibrating Screen Types Working Principle [How To Choose Highfrequency vibrating screens are usually operated at an angle of inclination, traditionally varying between 0 and 25 degrees, up to 45 degrees In addition, it should operate at a low stroke with a frequency range of 15007200 RPMVibrating Screen Mineral Processing

Highfrequency vibrating screens Wikipedia

Its high frequency characteristics differentiates it from a normal vibrating screen The high frequency vibrating screens usually operates at an inclined angle, traditionally varying between 0 and 25 degrees and can go up to a maximum of 45 degrees Besides, it should operate at a low stroke and has a frequency ranging from 1500 7200 RPMThe screening accuracy and output of the vibrating screen cannot meet the requirements 213月20 zhenyingvibrate Frequent damage accidents of the main parts of the vibrating screen directly affect the production efficiency of the vibrating screen Do the daily maintenance and analyze the common failure causes to improve the working efficiency of the vibrating screen and extend its service The screening accuracy and output of the vibrating screen Unique design and construction makes maintenance and parts replacement simple When the longwearing screen cloth must be changed, access ports in the sides of the screen body simplify the job Vibrating mechanism can be removed from either side of the screen body Mechanism is lubricated through grease pipes outside the screen bodyDillion Screen Features Vibrating Screens

Vibrating Screens Vibrating Screen Vibra Screw

Vibra Screw provides a wide variety of highly efficient vibrating screens for applications that require coarse scalping, multideck separation, or dewatering Each vibrating screen can be fitted with standard market grade or tensile bolting cloth, stainless steel mesh, nylon, or synthetic cloth, or bar screensGeneral Description Model “RVS” Rotary Vibrating Screens are ruggedly constructed units, designed to sift, separate, classify or scalp various materials by size The assembly is fabricated to provide maximum screen area with minimum drive and power requirementsService InstructionsEfficient Vibrating Screens Requirements linear vibrating screen is suitable for screening various dry powder or granular materials with particle size of 00745mm moisture content lt7 and no viscosity The feed particle size is not more than 10 mm Circular Vibrating Screen Circular vibrating screen is a new type of vibrating screen with multilayer screen and high efficiencyEfficient Vibrating Screens Requirements

Dewatering Screens Vibramech

Customised Design – Our Speciality Vibramech has over 40 years of vibrating equipment design and mineral processing experience, which enables us to supply screens, feeders, grease tables and drives best suited to our clients’ requirementsHighcapacity vibrating screens sieve machines for improving product quality and purity The Russell Compact Sieve ® range of round vibratory screens removes all oversized contamination and is ideal for high capacity safety screening of powders and liquid slurries These vibratory sieves fit neatly into production lines, providing considerable screening capacity without requiring excessive Circular Vibrating Screeners Vibratory Sieves, Russell FinexUsing empirical values of the materials obtained through lab tests, the vibrating screen is designed according to the features and requirements of the product to be processed The study of the particle, its composition, its shape and hardness is also very important Other important factors are:Vibrating screens Vibroprocess

The screening accuracy and output of the vibrating screen

The screening accuracy and output of the vibrating screen cannot meet the requirements 213月20 zhenyingvibrate Frequent damage accidents of the main parts of the vibrating screen directly affect the production efficiency of the vibrating screen Do the daily maintenance and analyze the common failure causes to improve the working efficiency of the vibrating screen and extend its service Highfrequency vibrating screens are usually operated at an angle of inclination, traditionally varying between 0 and 25 degrees, up to 45 degrees In addition, it should operate at a low stroke with a frequency range of 15007200 RPMVibrating Screen Mineral ProcessingEfficient Vibrating Screens Requirements linear vibrating screen is suitable for screening various dry powder or granular materials with particle size of 00745mm moisture content lt7 and no viscosity The feed particle size is not more than 10 mm Circular Vibrating Screen Circular vibrating screen is a new type of vibrating screen with multilayer screen and high efficiencyEfficient Vibrating Screens Requirements

Vibrating screen for solids and liquids Heilig Mixing

A vibrating screen is ideal for sifting, sieving, and separating solids, such as granulates and powders, as well as separation liquids from solids Heilig Mixing Technology can supply vibrating screens (or vibrating sieves) with a maximum of 4 sieving decks, offering 5 product fractionsThese vibrating screens have very low dynamic load minimising structure requirements All Derrick vibrating screens are of high quality construction and are built to last The Derrick Stack Sizer has a small footprint but a high capacity due to the vertical stacking of the vibrating screen decksVibrating Screens – Derrick Stack Sizer WPE Process Vibratory Screeners for Particle Separation Separation using vibratory screens relies on two general principals, probability and stratification Stratification of particles by size occurs as the bed of material on a vibratory machine is put into flight according to the specific microthrow characteristics of the machineVibratory Screens JVI Vibratory Equipment

LinaClass® SLK Linear vibrating screen

Schenck Process linear vibrating screens fulfil all these requirements perfectly They can handle the largest quantities of materials, and classify them to a high level of accuracy Driven by robust DF force exciters, they are specially adapted to the widest range of requirementsNormally, the vibrating motors are positioned at an angle of 50 degrees with respect to the screen surface This results in excellent forward conveyance of oversize particles, even when the screen frame is in an uphill position Depending upon the application, the screen frame can be positioned from 10 degrees uphill to 15 degrees downhillVibrating Screens – Wet Dry WPE Process EquipmentVariety of customizable sizes to suit a variety of industry scenarios and space requirements Larger throughput, decades of technical experience, continuous iterations to increase production Reliable product material, using selected highquality steel to create a longwearing vibrator Flexible combination system for easy connection to other conveyors and screening equipment Technical staff Vibrating Screen Vibrating Equipment Dahan Machinery

- neway cranck shaft grinding machine in lahore

- losche gypsum mill scribd

- crusher plant for sale in moroc

- pembuatan crusher tubara

- send hand grinding mills

- CRUSHER BEARING 3538

- milcent atta maker dealer in mumbai

- HOT SELLING HIGH EFFICIENCY CE ISO IQNET CONCRETE LINEAR VIBRATING SCREENS

- what type grinder machine used on grinding cement

- high quality grinding machine

- INTRODUCTION BALL MILLING

- middling ore magnetic separation

- ball mill installation manual

- what are the dissadvantages of mining iron ore

- rock crusher 2 250 ton per hour impact

- crushing and agglomeration process

- stone crusher demand in angola

- books on mminution ball mill australia

- venta de picadoras de forraje

- KAPASITAS DAN HARGA BALL MILL

- ore ne crusher stationary crusher

- layout of aggregate crushing sand crusher 400 mesh

- Best Teeth Roll Crusher Price Price For Supplier

- SMALL CAPACITY GOLD ORE BALL MILL

- Buy A Concrete Crusher Australia Gold Ore Crusher

- MINI ARTIFICIAL SAND MAKING MACHINE MANUFACTURERS INDIA

- CEMENT CONSUMPTION IN MCONCRETE 1 CUBIC METER

- mobile crusher jaw crusher send hand in south africa

- granite quarry in tamilnadu

- to how to calculate efficiency of a jaw crusher

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

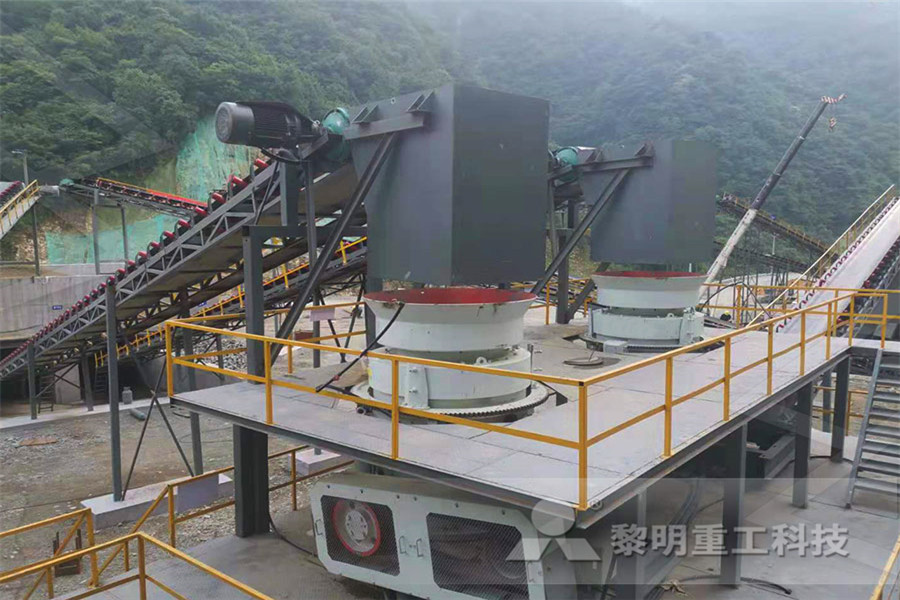

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

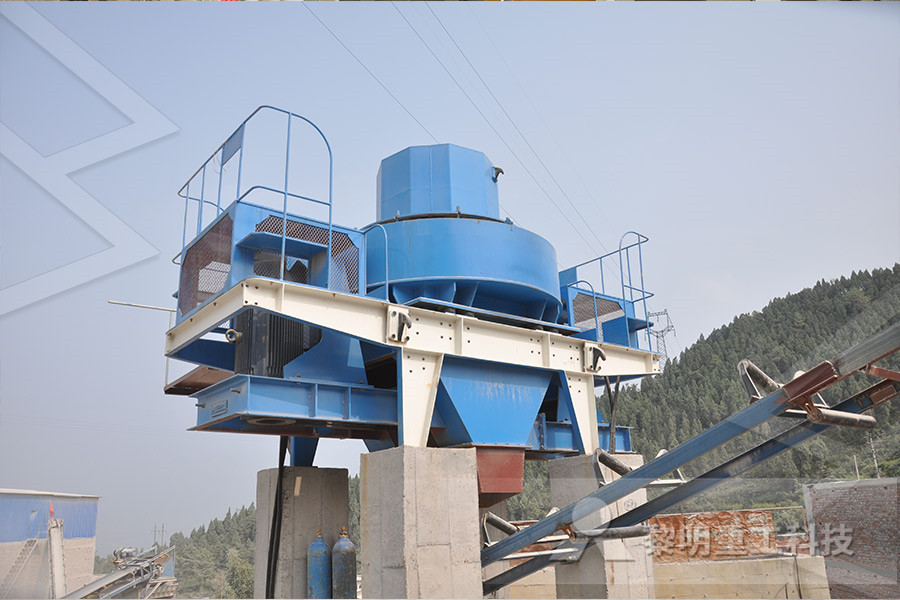

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine