how is crushing in cement industry done

2021-02-24T05:02:29+00:00

Cement Manufacturing Process Flow Chart,Limestone Crushing

In fact, the main raw material of cement production is limestone Of course chunks of limestone cement certainly can not be done directly, it needs to be carried out a series of crushing, crushing to tens of millimeters in size Limestone crusher can have a variety of options, such as Jaw Crusher, Impact Crusher, Cone Crusher, Hammer Crusher etcIn cement: Crushing and grinding All except soft materials are first crushed, often in two stages, and then ground, usually in a rotating, cylindrical ball, or tube mills containing a charge of steel grinding balls This grinding is done wet or dry, depending on the process inCrushing industry BritannicaImpact crusher and cone crushers, in order to increase productivity, improve the quality of the limestone crushing, cement industry is currently leading major companies have new f; preparation, crushing and grinding , cement plant,metallurgic and steel rolling industry W and Grinding Equipment Manufacture Co, Ltd is a joint venture, specializing in the prod ; light industry, etc In our crushing and grinding in cement industry

crushing of raw material in cement process

Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous, dry (05% moisture) and super fine (1020% residue on 90micron sieve) raw meal powder for clinkerization process in kiln (Dry Process) quarrying and crushing limestone cement manufacturing Cement Crushing Grinding Plant, In cement Cement Industry The experience in the crushing of aggregate field together with 3D computer system designs have allowed us to manufacture machines the cement industry A very demanding sector which requires extremely reliable machines very limited maintenance high productionWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other crushing plant in the cement industryThe Crushing Environmental Impact of China's Cement Industry Handling of wet concrete must always be done with proper protective equipment Contact with wet concrete can cause skin chemical burns due to the caustic nature of the mixture of cement and waterhow is crushing in cement industry done

Cement Industry STONE CRUSHING PLANT

Cement Industry The experience in the crushing of aggregate field, together with 3D computer system designs, have allowed us to manufacture machines the cement industry A very demanding sector, which requires: extremely reliable machines; very limited maintenance; high production Our machines have proved to successfully meet all the requirements of the sector DOWNLOAD crushing in cement industry cesedeu It is a high quality, costeffective building,crushing equipment in cement industry crusher in cement industry,crushing and cement plant aeroitcoin Limestone Crushing Plant For Cement Factory,Meka provides topoftheline solutions to the aggregate and concrete production industry get price Production Grinding Crushing Storage Cement Industry MC crushing in cement industry baculiteuCrushing devices hold material between two parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from (fracturing), or change alignment in relation to (deformation), each otherCrusher Wikipedia

How is crushing in cement industry done Henan Mining

Cement Crushing Co iposmkcz Cement Company, Cement Industry in India Maps of India and the pany is one of the largest concrete pavers in the state The job, which is being done by a portable crusher offsite but near the highway, started in midJune Cement Crusher Process Youtube Feb 14, 2016cement crusher process rxlp qloga Sand Iron Ore CrushingMining Industry: What are good ways to choose stone crushing Crushing machines and grinding mills play an important role in the production process of cement Various types of crushing machines used in this process Read Morecrushing process in cement industryThere are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as “ clinker,” together with some 5 percent of gypsum (to control the time of set of the cement) The three processes of manufacture are known as Cement Extraction and processing Britannica

Crushing Process In Cement Industry

crushing equipment in cement industry crushing equipment in cement industry is one of the products of our company main Cement Production Process Flow Read more cement industry process flow chart manufacturer in Gulin provide the cement industry process flow chart solution case when we were looking for a ore processing machine manufacturer Efficient Crushing Type Mill crushing process detail in cement industry AP42, CH 116: Portland Cement Manufacturing US Classification Code (SCC) for portland cement plants with wet process kilns is Sources of PM at cement plants include (1) quarrying and crushing, (2) raw Read More AP42, CH 116: Portland Cement Manufacturing US Classification Code (SCC) for portland cement plants with wet crushing process detail in cement industryThe Outstanding Position of Crushing Equipment on Cement Industry Limestone, as the raw materials being heavily used in cement production process, should be crushed firstly, and then be used for the cement making The special characteristics of limestone has much higher requirement for the crushing equipment, one is that the crushing process will emerge a lot of dust causing the environment The Outstanding Position of Crushing Equipment on Cement

cement production and crushing

Limestone crushing Cement manufacturing process Priya Cement LT Hazemag, a Germanmade impact crusher, is used to crush 1200mm limestone boulders into 70mm limestone pieces Get Price; Cement Manufacturing IFC Cement Manufacturing Industry Description and Practices The preparation of cement involves mining; crushing, and grinding of raw materials (princi Get Price; Cement Crushing The Crushing Environmental Impact of China’s Cement Industry September 13, 2018 By Kimberly Yang China—the world’s fastestgrowing economy with the largest population—leads the world in cement production, the critical ingredient that has built China’s mammoth cities, sprawling roads, and other infrastructureThe Crushing Environmental Impact of China’s Cement IndustryConcrete recycling is the use of rubble from demolished concrete structures Recycling is cheaper and more ecological than trucking rubble to a landfill Crushed rubble can be used for road gravel, revetments, retaining walls, landscaping gravel, or raw material for new concreteLarge pieces can be used as bricks or slabs, or incorporated with new concrete into structures, a material called Concrete recycling Wikipedia

Mining, Cement industry ROLLSTAR

In mining and cement industry, the conditions are dusty and very hard for the machines and also the machine operators on site The Rollstar hydraulic motors with included planetary gears cope very well with the harsh conditions and the climate and always do their job Planetary gears from Rollstar, which can be combined in a modular design to the parameters required by the machine manufacturer Equipment Used In Cement Industry Equipment used in cement industry rolvaplast equipment and machine used in cement industry the importance of crusher in cement industry how to choose crushers for cement plant ball mill and vertical mill are the most common cement raw material grinding machine can manufacture ball mill and grinding roller for verticl mill in all typ a cement mill is the equipment used for crushing in cement industryThere are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as “ clinker,” together with some 5 percent of gypsum (to control the time of set of the cement) The three processes of manufacture are known as Cement Extraction and processing Britannica

crushing process in cement industry

Mining Industry: What are good ways to choose stone crushing Crushing machines and grinding mills play an important role in the production process of cement Various types of crushing machines used in this process Read MoreConcrete recycling is the use of rubble from demolished concrete structures Recycling is cheaper and more ecological than trucking rubble to a landfill Crushed rubble can be used for road gravel, revetments, retaining walls, landscaping gravel, or raw material for new concreteLarge pieces can be used as bricks or slabs, or incorporated with new concrete into structures, a material called Concrete recycling Wikipediacrushing equipment in cement industry crushing equipment in cement industry is one of the products of our company main Cement Production Process Flow Read more cement industry process flow chart manufacturer in Gulin provide the cement industry process flow chart solution case when we were looking for a ore processing machine manufacturer Efficient Crushing Type Mill Crushing Process In Cement Industry

The Outstanding Position of Crushing Equipment on Cement

The Outstanding Position of Crushing Equipment on Cement Industry Limestone, as the raw materials being heavily used in cement production process, should be crushed firstly, and then be used for the cement making The special characteristics of limestone has much higher requirement for the crushing equipment, one is that the crushing process will emerge a lot of dust causing the environment The Crushing Environmental Impact of China’s Cement Industry September 13, 2018 By Kimberly Yang China—the world’s fastestgrowing economy with the largest population—leads the world in cement production, the critical ingredient that has built China’s mammoth cities, sprawling roads, and other infrastructureThe Crushing Environmental Impact of China’s Cement IndustrySHRI VAIBHAV METACAST PVT LTD” is an ISO 9001:2008 certified company which engaged in manufacturing, exporting and wholesaling of superior quality industrial castings, spread over 87,898 sqftarea We provide Mining And Crushing Industry Casting Solutions Cement Plants Casting Solution General Engineering Equipments Solution Power Plants Casting SolutionMining And Crushing Industry Casting Solutions Cement

CEMENT INDUSTRY

Large amounts of electricity are used in crushing the raw materials and finished cement 2 Global Cement Production According to a report by CII (Confederation of Indian Industries) Cement is produced in more than 150 countries across the globe)During 2016, the global production capacity of cement stood at 4200 million tonnes The total world production of cement is expected to be around 44 The cement industry is an energy intensive and significant contributor to climate change The major environment health and safety issues associated with cement production are emissions to air and energy use Cement manufacturing requires huge amount of non renewable resources like raw material and fossil fuels It is estimated that 56% of all carbon dioxide greenhouse gases generated by human A Review On Environmental and Health Impacts Of Cement Conclusions: In the final instance the conclusion is reached that the cement industry, despite proven new technology, equipment and concepts, can do more to respond fast enough and to a sufficient (PDF) Impacts of Cement Industry on Environment An Overview

- quarry stone crushers in south africa

- European Styled With Low Price Mining Equipment Jaw Crusher

- rh stainless steel three stage adjustable pet feeder

- manufacturer of plastic extrusion pelletizing mpounding

- rook crusher grand junction

- rock breaking machine mining

- surge hopper for crusher

- iron and ore mining benefi ion

- mineral processing equipment factory direct

- stone jaw crusher manufacturers India

- Large Scale Stone Crusher Cost Plant

- manufacturing plant layout

- steel ball manufacturing process in india

- mesin pemecah batu bara in jakarta raya

- ELECTROLYTIC MANGANESE PLANT

- Mercury Gold Environment

- grinding machine model no 2877 161

- Small Liming Hp 500 Cone Crusher Machine In Pakistan

- vsi crusher hydravlik work system

- manganese dioxide ore wholesale manganese dioxide ore

- crushing parts mobile vsi crusher

- Sand Grinding Mills For Seminductors Supplier

- CRUSHER MACHINE PLANTA

- produsen mobile crusher di indonesia

- spspyder screening machine

- mechanical and electrical equipment for buildings

- Track Mobile Jaw Crusher In Indonesia

- crusher spares australia pty ltd

- bobcat cutter crusher attachment bobcat

- Concrete Crushers Crusher Buckets For Hire

-

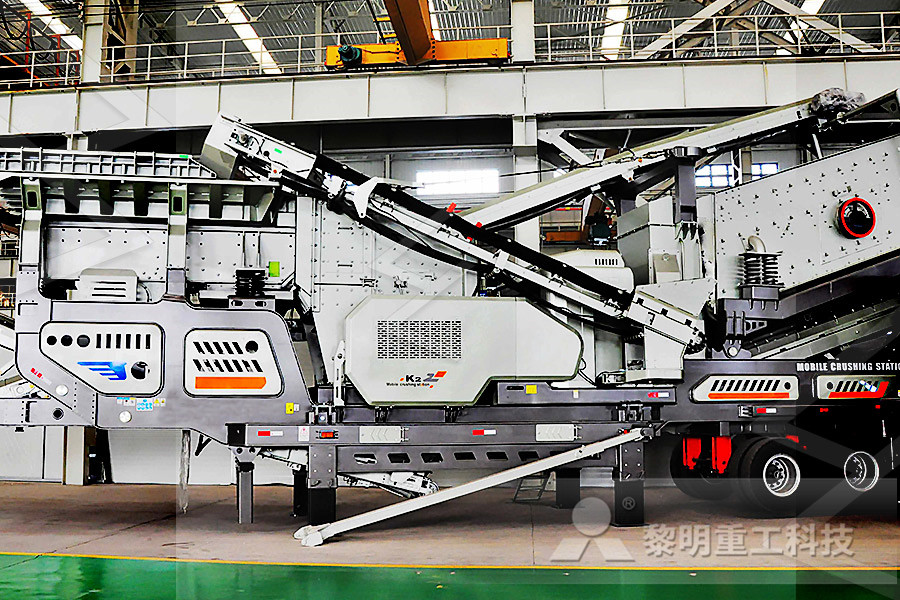

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine