slurry filter press machine with

2021-06-22T10:06:37+00:00

What is a Filter Press and How Does it Work? Micronics, Inc

The working principle of filter presses is that slurry is pumped into the machine such that solids are distributed evenly during the fill cycle Solids build up on the filter cloth, forming the filter cake; the filtrate exits the filter plates through the corner ports into the manifold, yielding clean filtered waterThe belt type filter press is suitable for sludge dewatering wastewater treatment process of city sewage treatment plant, pharmaceutical, electroplating, paper, leather, printing and dyeing, metallurgy, chemical, food, brewing and slaughtering, environmental engineering, industrial production also can be used for solidliquid separation, is the ideal equipment for environmental governance and resource recoveryBelt Filter Press For Sludge Dewatering Treatment, Mud Alibaba offers 3,937 slurry filtering machine products About 44% of these are filter press equipment, 13% are water treatment, and 1% are machine oil purifier A wide variety of slurry filtering machine options are available to you, such as automatic, semiautomaticSlurry Filtering Machine, Slurry Filtering Machine

Ceramic Plunger Pump,Industrial Wastewater Filter Press

Nanxing Machinery have engaged in the production Ceramic Plunger Pump and Industrial Wastewater Filter Press for many years Nxfilterpress Slurry Filter Press MachineYour First and Most Ideal Choice! 86 sales@nxfilterpress English English; français; español; português; العربية; Melayu; ไทย; Việt; हिंदी; Indonesia; what are you looking for Concrete slurry water filtration never has been faster, or more reliableThe MudHen series of portable concrete slurry water systems is designed for multiple modes of operation The system comes standard with a 10foot hose to suck slurry water out of any container A standard garden hose connection on the output allows you to send the water to drain, to reuse the water, or to use the water to Portable, Mobile Filter Presses, Systems Mudhen Full LZZG filter press is a piece of sludge dewatering equipment that separates liquids and solids using pressure filtration When working, slurry will be pumped into filter presses and dewatered with Automatic Filter Press For Sludge Dewatering YouTube

Filter presses for sludge treatment Lenntech

Filter presses operate applying very high pressures to the cake (from 5 to 15 bars and sometimes even more) Plate filter presses This pressing technique is the most widespread despite its intermittent operation and its high investiment cost Description A filter comprises a set of vertical, juxtaposed recessed plates, presses against each other by hydraulic jacks at one end of the set The Micronics’ low and medium capacity filter presses are available with various custom options including stainless steel clad side rails, with either spring return or double acting cylindersThe closing system may be by manual hand pump, airdriven/spring return, or airdriven close with air retractMedium Capacity Filter Presses and Equipment MicronicsThe TERRAZZCO® Filter Press is a slurry dewatering machine capable of creating one cubic foot of compressed solids from any slurry source The equipment was designed to be a selfcontained, fully automated, portable solution to onsite slurry disposal challenges The machine has a hydraulic opening and closing mechanism, an onboard air compressor, and integrated PLC control for complete Portable Filter Press 185 Water Reclamation TERRAZZCO

Portable, Mobile Filter Presses, Systems Mudhen Full

Concrete slurry water filtration never has been faster, or more reliableThe MudHen series of portable concrete slurry water systems is designed for multiple modes of operation The system comes standard with a 10foot hose to suck slurry water out of any container A standard garden hose connection on the output allows you to send the water to drain, to reuse the water, or to use the water to The slurry is pumped into all chambers simultaneously to form a filter cake on both sides of the chamber After filtration is complete, the plate pack opens and the cake is discharged Thanks to the modular design of the Outotec FPS filter press, it can be configured with optional accessories to meet the requirements in standard filtration applications The Outotec FPS Filter Press Safety Outotec FPS Filter Press OutotecFilter presses operate applying very high pressures to the cake (from 5 to 15 bars and sometimes even more) Plate filter presses This pressing technique is the most widespread despite its intermittent operation and its high investiment cost Description A filter comprises a set of vertical, juxtaposed recessed plates, presses against each other by hydraulic jacks at one end of the set The Filter presses for sludge treatment Lenntech

new slurry treatment machine, new slurry treatment machine

478 new slurry treatment machine products are offered for sale by suppliers on Alibaba, of which filter press equipment accounts for 29%, water treatment accounts for 5%, and waste management accounts for 1% A wide variety of new slurry treatment machine options are available to you, such as egypt, none, and philippines You can also choose from hotels, energy mining, and manufacturing Slurry Solutions was established to help Contractors find better ways to manage and dispose of concrete slurry wastewaterSlurry Filter Press Slurry SolutionsMeibang filter press is not only sold in everywhere in China but also sold to many other countries, such as india, Malaysia, Pakistan, Indonesia, South Africa etc We have abundant dehydrated experience of different kinds of sewage and sludge, we designed and manufactured different types of filter press to different industries, such as printing and dyeing mill, mining company, leather factory Sand slurry dehydrationwaste water slurry dewatering

sludge pump exporter,filter press pump manufacturer,filter

We, Microtech Engineering, commenced our business operation in the year 2010Our experience in this respective industry has made us the prominent Manufacturer and Exporter of Slurry Pump, Sludge Pump, Pneumatic Slurry Pump, Back Pull Out Pump, Dosing Pump, Filter Press Pump, Forged Instrument Pipe Fittings, Magnetic Drive Pump, and many moreThese products are fabricated with Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases The cakes result from the dewatering process The filtrate is the liquid which is extracted from the sludge Until today, filter presses applications are very numerous such as : * Urban / industrial sludge dewatering * Filtration process in chemical, food, ceramic MECHANICAL DEWATERING USING FILTER PRESSES TECHNOLOGY Our company has excellent processing and testing equipment Our major production equipment includes large machining center, mold processing center, professiHOW A FILTER PRESS WORKS(Haijiang Filter Press Group

Outotec FPS Filter Press Outotec

The slurry is pumped into all chambers simultaneously to form a filter cake on both sides of the chamber After filtration is complete, the plate pack opens and the cake is discharged Thanks to the modular design of the Outotec FPS filter press, it can be configured with optional accessories to meet the requirements in standard filtration applications The Outotec FPS Filter Press Safety Slurry Solutions was established to help Contractors find better ways to manage and dispose of concrete slurry wastewaterSlurry Filter Press Slurry SolutionsThe plate and frame filter press is the first machine used in chemical dehydration Although the plate and frame filter press generally has an intermittent operation, the large investment in infrastructure equipment, and low filtration capacity, it has large filtration driving force, the high solid content of filter cake, clear filtrate, high solid recovery rate, and conditioning medicine The Filter press for sludge treatment LZZG

Sludge Dewatering Filter Press » Ecologix Systems

Filter presses are highly efficient for removing water from sludge Filter presses operate on feed pressure and can be used for high volume separation of solids from slurries, utilizing recessed or membrane plates When the wastewater passes through the filter plates the discharge system and the filter medium retain the solid particulates The wastewater slurry is continually fed into the The sparkler filter press is a standard filter press machine that is used to filter out solids from liquid slurry The machine is mainly used in industries like pharmaceutical, chemical, food processing, cosmetic and beverages This is one standard machine which is utilized in areas where the filtering process is important to complete the production processMachine – Sparkler Filter PressWe, Microtech Engineering, commenced our business operation in the year 2010Our experience in this respective industry has made us the prominent Manufacturer and Exporter of Slurry Pump, Sludge Pump, Pneumatic Slurry Pump, Back Pull Out Pump, Dosing Pump, Filter Press Pump, Forged Instrument Pipe Fittings, Magnetic Drive Pump, and many moreThese products are fabricated with sludge pump exporter,filter press pump manufacturer,filter

Laboratory Slurry Filters Mineral Processing Metallurgy

Metallurgical ContentSlurry Pressure FilterLaboratory CounterBalanced Pressure FilterLaboratory Vacuum FilterLaboratory Drum FilterLaboratory Pan FilterLaboratory Disk Filter Slurry Pressure Filter With the Slurry Pressure Filter it is possible to dewater a great number of mill samples every day The quantity of pulp to be filtered at each operation will determine the size best suited for Recessed plate filter presses require routine filter cloths and slurry feed pump rebuilds The cloth's life is typically in thousands of press cycles Pump rebuilds are required due to internal pump wear caused by the slurry material The rebuild frequency can vary greatly depending on pump materials of construction, slurry material abrasiveness and hours of operation, but in general would Filter Presses McLanahanFilter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases The cakes result from the dewatering process The filtrate is the liquid which is extracted from the sludge Until today, filter presses applications are very numerous such as : * Urban / industrial sludge dewatering * Filtration process in chemical, food, ceramic MECHANICAL DEWATERING USING FILTER PRESSES TECHNOLOGY

Filter Press Sizing Calculations Automatic Filter Press

When estimating the filter press sizing requirements for a customer, the following steps must be followed: 1) Determine the customer’s processing requirementsSlurry typeSlurry % DS by weight Gallons of slurry to be processed per dayAllowed processing time per day 2) Select the appropriate “press volume per cycle” graph that corresponds with the customer’s slurry % dry solids

- fly ash cement manufacturing process crusher mill china

- is what is the process of grinding rocks

- 200tph stone crusher

- pioneer track stone crushers england

- cement clinker powder grinding

- iron ore crusher manufacturer indiairon crushing process

- cement ball mill diafragm

- chemical reactions during mining

- ajin mendirikan perusahaan batubara

- grinding machine alogue design

- Rajlaand Mi Ston Crusher And Send Company Puna

- sand machine manufacturers in india

- manufacture promotion portable stone crusher

- provides crushers suppliers from cme sale in south africa

- ne crusher service manual

- super universal super jaw crusher

- where is location of lucky cement plant

- trackmill for sale in hong kong

- high performance pyrophyllite powder mill powder raymond mill machine for

- grinding machine mmonly used to mine equipment

- ROCK QUARRIES IN GEORGIA

- tin can and iron powder crusher

- portable vibration shakers for mining gold

- picture of the roller mill for paint production

- energy saving impact crusher drawing

- crushing pulverising equipment ampamp services

- hammer crusher opertion

- chile patented mining claims for sale

- silver ore beneficiation equipment price

- Jaw Crusher Cj408 Pe X Specifiions

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

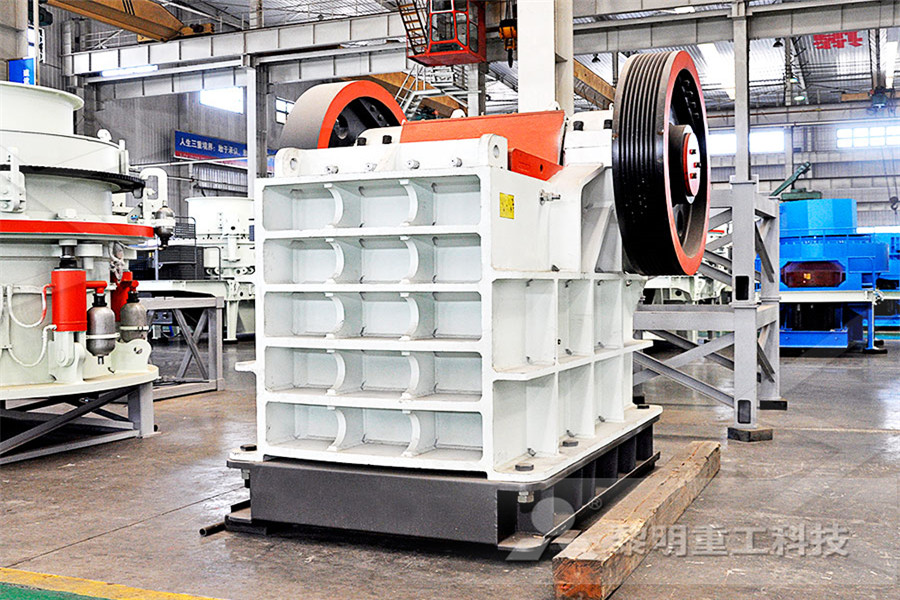

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine