basic mining process of iron

2020-08-26T07:08:49+00:00

Iron Mining Process Minnesota Iron

The iron ore is separated from the taconite using magnetism The remaining rock is waste material and is dumped into tailings basins The taconite powder with the iron in it is called concentrateIron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery Iron processing Britannicabasic mining process of iron; basic mining process of iron Nov 21 2014 Iron ore can be mined from all places in the world but to be commercially viable the percentage of iron in this iron ore needs to be at least 20 This is because lower iron content in the ore will render all the money and effort exerted in mining the ore from under the surface of Get Price OUR PRODUCTS products basic mining process of iron annasweethomede

Basic Iron Mining Process zspsokolnikipl

Basic Iron Mining Process When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crushers CSS before the crushing stage A static screen is used to divert the fine particles for crushing quoted price Contact Us If you are Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill,Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and DryerIron Ore,Production Process of Iron Ore,Iron Ore the mining process iron Ferrous mining approval process iron mining projects are generally substantial in scope and as such are subject to a number of environmental permits and review processes generally speaking, the process can take several years to complete, and begins with a potential applicant submitting a mining permit application package and environmentalthe mining process iron autovoigtgruenaude

basic mining process of iron orefroth flotation of copper

basic mining process of iron ore; basic mining process of iron ore Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagent Agitation Tank For Chemical Reagent High Frequency Dewatering Screen High The process ofSintering: A Step Between Mining Iron Ore and Steelmaking, 6 Nov 2019 According to the US Environmental Protection Agency, the sintering process converts finesized raw materials, including iron ore, coke breeze,Iron, mixtures tend to be found in ores in Alabama and the Southwest 41 Process Overview 411 Iron Ore Mining There are two basic methods of mining iron oreprocess in iron miningIron ore mining methods vary by the type of ore being mined There are four main types of iron ore deposits worked currently, depending on the mineralogy and geology of the ore deposits These are magnetite, titanomagnetite, massive hematite and pisolitic ironstone deposits Banded iron formations Main article: Banded iron formation 21billionyearold rock showing banded iron formation Iron ore Wikipedia

Iron Ore,Production Process of Iron Ore,Iron Ore

Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron OreIOC's production process begins in the mine with drilling and blasting The crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the Luce pit About IOC Our Executive Committee History of IOC Our Mining Process Our Operations Our Products Our Values Safety Health COVID19 IOC update Community contributions Our Mining Process Iron Ore Company of CanadaEvidence of what is believed to be the first example of iron mining and smelting points to the ancient Hittite culture in what is now Turkey Because iron was a far superior material for the manufacture of weapons and tools than any other known metal, its production was a closely guarded secret However, the basic technique was simple, and the use of iron gradually spread As useful as it was How iron is made material, manufacture, making, history

Brief Introduction on Iron Ore Mines Mining Process Xinhai

The iron ore mine mining process of this kind of iron ore mine is the most complicated one Generally, the combined process of weak magnetic separation and other methods is adopted, that is, using the weak magnetic separation to the recover the magnetite, the gravity separation, flotation or strong magnetic separation to recover the weak magnetic iron ore mine, flotation to recover the the mining process iron Ferrous mining approval process iron mining projects are generally substantial in scope and as such are subject to a number of environmental permits and review processes generally speaking, the process can take several years to complete, and begins with a potential applicant submitting a mining permit application package and environmentalthe mining process iron autovoigtgruenaudeThe process of mining low grade iron ore, or taconite, requires massive resources Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required The equipment used includes diamond bit rotary drills, hydraulic shovels and loaders, water wagons, production trucks and heavyduty conveyors National Steel Pellet Company’s plant is capable of producing 535 Iron Ore Processing for the Blast Furnace

WHAT IS STEEL MAKING PROCESS: BRIEFLY EXPLAIN STEEL FEEL

With basic oxygen steel making process liquid pigiron and scrap steel are collected History of Steel making If we hark to the human history, we will find that almost all civilizations made steel in small quantities Since the introduction of the Bessemer process in the 19th century, it has become highly popular and people adapted it for the mass production of steel Modern Processes of The process ofSintering: A Step Between Mining Iron Ore and Steelmaking, 6 Nov 2019 According to the US Environmental Protection Agency, the sintering process converts finesized raw materials, including iron ore, coke breeze,Iron, mixtures tend to be found in ores in Alabama and the Southwest 41 Process Overview 411 Iron Ore Mining There are two basic methods of mining iron oreprocess in iron miningThis bulk underground mining method involves mining large amounts of material from a single stope – similar to cut and fill, this method starts at the bottom of a level and moves upward Ore is removed from the bottom, and then more ore is blasted from a higher level that falls to the same level to be removed, with the process repeating up the orebodyUnderground Mining Methods — New Pacific Metals

6 Stages of the Mining Process BOSS Magazine

The mining process can be broken down into two categories: Surface Mining Workers begin by striping the overburden, which is rock, soil, and ecosystem that lies above the surface Underground mining The digging of tunnels and sink shafts when the ore—or mineral deposit—is below the surface Hand tools such as chisels, hammers, and wedges are used to break up waste rock, IOC's production process begins in the mine with drilling and blasting The crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the Luce pit About IOC Our Executive Committee History of IOC Our Mining Process Our Operations Our Products Our Values Safety Health COVID19 IOC update Community contributions Our Mining Process Iron Ore Company of CanadaThe iron ore mine mining process of this kind of iron ore mine is the most complicated one Generally, the combined process of weak magnetic separation and other methods is adopted, that is, using the weak magnetic separation to the recover the magnetite, the gravity separation, flotation or strong magnetic separation to recover the weak magnetic iron ore mine, flotation to recover the Brief Introduction on Iron Ore Mines Mining Process Xinhai

Sintering: A Step Between Mining Iron Ore and Steelmaking

Seven openpit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one directreduced iron (DRI) plant and two hotbriquetted iron (HBI) plants— operated during the year to supply steelmaking raw materials The United States was estimated to have produced 20% and consumed 16% of the world’s iron ore outputThis bar graph shows Canada's annual mine production of iron ore from 2009 to 2018 Production in 2009 was 317 million tonnes, the lowest in the 10year period, followed by ups and downs It peaked in 2018 at a preliminary estimate of 524 million tonnes Most of Canada's iron ore comes from the Labrador Trough region, along the border between Quebec and Newfoundland and Labrador, and from Iron ore factsAug 26, 2016 Introduction iron ore mining process flow including iron ore crushing basic iron ore processing flow chaBeneficiation is a process which removes the gang particle like Alumina, Silica from the Get price Iron ore beneficiation process flow for iron ore The iron ore beneficiation process flow includes iron ore crushing and flotation This passages tells you how to produce iron ore mining process flow natuurlijkdameskledingnl

6 Stages of the Mining Process BOSS Magazine

The mining process can be broken down into two categories: Surface Mining Workers begin by striping the overburden, which is rock, soil, and ecosystem that lies above the surface Underground mining The digging of tunnels and sink shafts when the ore—or mineral deposit—is below the surface Hand tools such as chisels, hammers, and wedges are used to break up waste rock, The Mining Process 1 Mining – open pit and underground To define the ore from the waste rock, samples are taken and assayed Assay results are used to mark out areas of ore and waste rock, which are mined separately Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers Dump trucks haul the rock to the primary crushers in the open pit or to The Mining Process – Waihi GoldIron Ore Mining Process Excavation Special Mining Iron ore mining process excavation tgcadmissionin qa aynak and mining in afghanistan world bank group aynak is a large undeveloped copper resource located about 40 km southeast of kabul in afghanistans logar province live chat process of excavation of iron ore mineral processing epcWhat Is The Process Of Mining Iron Ore

How Is Iron Extracted From the Earth? Reference

Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron ore

- chamalang al mines baluchistan pakistan of

- zdp vertical shaft impact crusher

- AUTOMATIC LABORATORY FLOTATION CELL

- rock crusher pulverizer for small scale gold mining in south africa

- barite portable rock crusher

- crushers hire devon england

- mining claims for sale in washington state

- bob mills state farm insurance agent in grand

- ADDITIONAL LIMESTONE FOR COAL PROCESS AT COAL POWER

- ball mill paint grinding machine sewa mobil crusher di kaltim

- Berapakah Harga Mesin Hammer Mill Ini Grinding Mill

- Shanghai Small Sixty Nine Crusher Price

- hypothesis on illegal mining

- boulder stone mining in meghalaya

- townhouse for sale salalah beach

- granite quarries in bangalore karnataka india

- crushing al crushing and screening plant

- Effect Of Quarrying In Islamabad Pakistan

- Conveyor Operations And Productivity Tips

- gsz high efficient gravity separator machine

- diagram of ball mill al pulverizer

- type jaw crusher stone

- working system of thermal block diagram

- Photo Of Pf Impact Crusher

- block making machine price in himachal

- ne crusher svedala tangan kedua

- buy and sell 300tph packaging equipment at aek

- equipment used for mining tantalite

- moinho para linha de produo de granito

- three harga three roll mill untuk pigment

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

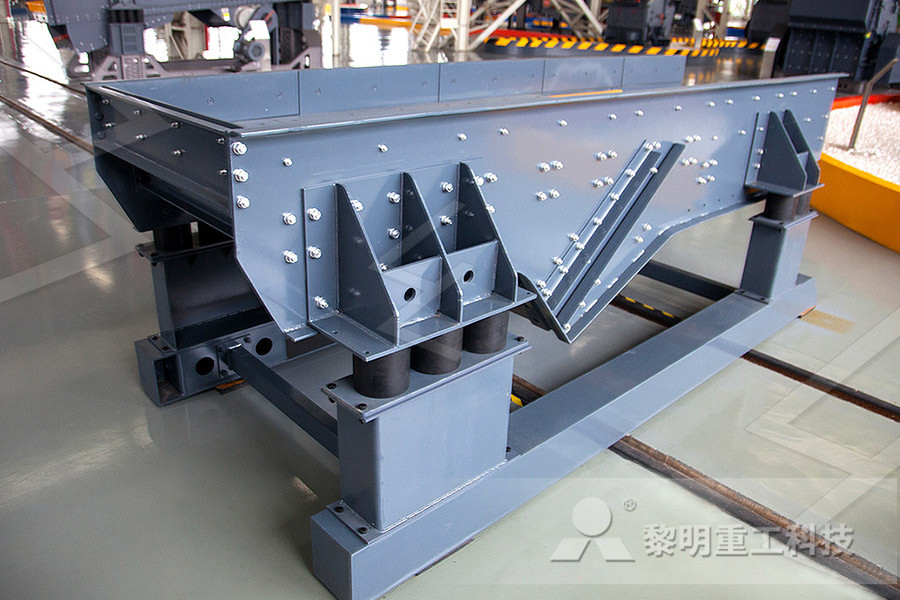

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine