manufacturing process tubes

2020-10-29T06:10:36+00:00

Stainless Steel Pipe and Tube Manufacturing Process

Stainless Steel Pipe and Tube Manufacturing Process Tube mill Process description: Rolling and welding; Firstly, the stainless steel strips are made to gone through various quality checks and are trimmed at edges They are then fed to the tubes mill by stainless steel pipe manufacturers in India The strips pass through the number of rollers Seamless Pipe Manufacturing Process Seamless pipe is Strongest amongst all pipes type as it has a Homogeneous structure throughout pipe length Seamless pipes are manufactured in a verity of size and scheduleHowever, there is a Restriction on the manufacturing of large diameter pipePipe Manufacturing Process / Methods for Seamless Welded Tube Manufacturing We offer our clients in the aerospace, automotive, biotech, medical, and military industries the best in tube manufacturing technology We feature all the leading tube drawing methods, including tube sinking, stationary, floating, semifloating plug drawing, pilger, and drawn over mandrelTube Drawing and Manufacturing Tube Methods, Inc

The Manufacturing Process of Seamless Tubes Anandseamless

Dec 07, 2018 Due to this, many new processes have surfaced that makes the whole manufacturing process of seamless tubes, easy and costeffective But the most popular process that has caught on with many manufacturers in the process of continuous tube mill No forge welding or filler metal is used in this new technique Seamless Tube Manufacturing Process 1The manufacturing process for aswelded mechanical tubing begins with coils of steel, which are slit to the proper width for the desired tube size The cut strip, or skelp, passes through a series of rolls that progressively coldform it into a tubular shape It then passes through an electric resistance welder which joins the edges Read moreManufacturing Process Mechanical TubingThis section does not cite any sources Please help improve this section by adding citations to reliable sourcesUnsourced material may be challenged and removed December 2009) (Learn how and when to remove this template message) This tree lists various manufacturing processes arranged by List of manufacturing processes Wikipedia

Steelmaking: Tube Manufacture YouTube

Jul 26, 2007 Spiral Welded Pipe Manufacturing Process Duration: 2:07 Murray Roberts Webmaster 134,928 views 2:07 Mega Diesel Engines How To Build A 13,600 HP Engine Full Documentary Duration: 49:03The purpose of this article is to take you through the process they use in the ointment manufacturing plants for the production of the ointments and filling them in tubes So, let's move to the procedure directly without wasting any timeManufacturing Procedure of Ointment and Tube Filling Before each step of the drawing process, the tube is pointed at one end to fit through the next die, whereupon it is gripped by automatic jaws attached to a rotating, 7ftdiameter drawing machine called a bull block A tapered plug mandrel, which may be either fixed or floating depending on the process used, is placed inside the tubeHow Do They Do That? Making Copper Plumbing Tube

Lean manufacturing in producing square, retangular tubing

For tube, pipe, and profile production, reducing the downtime between production runs is one of the most effective ways to reach lean manufacturing objectives Flexible Cold Forming ® (FCF) is a cage forming process that provides an alternative to the conventional forming process It reduces mill downtime and can help a tube producer remain Manufacturing process In essence the manufacturing process is a continuous process Starting from steel strip continuing with the formation and welding, annealing, surface treatment, threading, drawn, cutting tips, long commercial cuts, nondestructive testing, packaging and finally dispatching once the finished tube is obtained, according to customer requirementsPrecision steel tubes manufacturing processThe manufacturing process for DOM tubing begins with coils of steel, which are slit to the proper width for the desired tube size The strip is cold formed and passed through an electric resistance welder which joins the edges together, under pressure, to complete the tubular shape After testing the weld’s integrity, the tubing is Read moreManufacturing Process Drawn Over Mandrel

Tube (container) Wikipedia

A tube, squeeze tube, or collapsible tube is a collapsible package which can be used for viscous liquids such as toothpaste, artist's paint, adhesive, caulk, ointments, and so onBasically, a tube is a cylindrical, hollow piece with a round or oval profile, made of plastic, paperboard, aluminum, or other metalIn general, on one end of the tube body there is a round orifice, which can be Feb 23, 2019 Food manufacturing involves strict processes through which ingredients are combined and turned into snacks, meals, and other foods we eat on a daily basis If you've ever wondered how food Satisfying Food Manufacturing Process You Must SeeSteel pipes are long, hollow tubes that are used mainly to convey products from one location to another They are produced mainly by two distinct manufacturing methods which result in either a welded pipe or seamless pipe In both the manufacturing methods, raw steel is first cast into a more workable starting form (hot billet or flat strip Introduction to Seamless Pipe Manufacturing The Process

Method of manufacturing tire inner tubes Dunlop Limited

Dec 14, 1976 A method of manufacturing tire inner tubes in which the tube is moulded in two annular parts from worked uncured rubber, and the parts are joined but before curing of the rubber is completed the tube is stretched to a larger internal diameter and inflated into a mould with the larger internal diameterFor increased strength and properties in all directions, filament winding is an effective method in manufacturing carbon fiber tubes Filament wound tubes are cost effective and have excellent properties, however, the largest limitation is based on the length of the winding machineHow Carbon Fiber Tubes Are Made ThoughtCoTubing Manufacturing Process Our production process combines proven methods and new technologies to consistently produce TIG welded and mandrel drawn tubing of very high quality at economical costs American Tube uses the Tungsten Inert Tubing Manufacturing Process American Tube

Glass tube Wikipedia

Manufacturing Process Glass tubes are produced in various types of glass and in diameters ranging from a few millimeters to several centimeters In most production processes, an "infinitely long" glass tube is drawn directly from the melt, from which approximately 15 m long pieces are chopped off after passing a roller track up to the drawing Extrusion molding is another method of manufacturing plastic components Extrusion molding is very similar to injection molding and is used to make pipes, tubes, straws, hoses and other hollow pieces Plastic resin is fed into a barrel where it is liquefiedThe Plastic Manufacturing Process SciencingGlass can be shaped, cut, drilled, polished, marked, and sterilized to meet your application Glass is clean and inexpensive making it perfect for disposable medical or clinical laboratory applications There are many glass tube manufacturing processes Here is more information about the accuglass processGlass Tube Manufacturing Processes AccuGlass LLC

Manufacturing Process Drawn Over Mandrel

The manufacturing process for DOM tubing begins with coils of steel, which are slit to the proper width for the desired tube size The strip is cold formed and passed through an electric resistance welder which joins the edges together, under pressure, to complete the tubular shape After testing the weld’s integrity, the tubing is Read moreELBOWS Manufacturing Process: Mandrel method (Hot Forming) One of the most common Pipe Fittings Manufacturing Process for manufacturing Elbows from the pipe is mandrel method which is kind of hot forming methods In this method, the pipe is cut in Pipe Fittings Manufacturing Process for Elbow, Tee, Cap Manufacturing process In essence the manufacturing process is a continuous process Starting from steel strip continuing with the formation and welding, annealing, surface treatment, threading, drawn, cutting tips, long commercial cuts, nondestructive testing, packaging and finally dispatching once the finished tube is obtained, according to customer requirementsPrecision steel tubes manufacturing process

Silicon carbide manufacturing process GAB Neumann

Manufacturing process of silicon carbide plates, blocks, and tubes The silicon carbide manufacturing process includes numerous steps namely, powder preparation, mixing with the binder, shape forming, machining, sintering, and eventually lapping or grindingThe amount of care and attention to detail found at this plant is absolutely amazing These tubes are actually built better than the older 300Bs To my surprise, some of the manufacturing processes are greatly improved, making for a more consistent product The upcoming tubes from Western Electric are the 274B, KT88 (GOLD LION), and 308A among Western Electric 300B Vacuum Tube ManufacturingManufacturing Process Glass tubes are produced in various types of glass and in diameters ranging from a few millimeters to several centimeters In most production processes, an "infinitely long" glass tube is drawn directly from the melt, from which approximately 15 m long pieces are chopped off after passing a roller track up to the drawing Glass tube Wikipedia

Glass Tube Manufacturing Processes AccuGlass LLC

Glass can be shaped, cut, drilled, polished, marked, and sterilized to meet your application Glass is clean and inexpensive making it perfect for disposable medical or clinical laboratory applications There are many glass tube manufacturing processes Here is more information about the accuglass processWorld Class Tube Manufacturing High quality, tight tolerance tubing has been a benchmark of Welded Tubes throughout its more than 60 year history We invest annually in new equipment and process improvements to provide our customers a faster response time and a world class tubing productProcess Welded Tubes, IncManufacturing Process For the effective and bulk production of Steel Pipes Tubes, we have developed a sophisticated manufacturing unit Equipped with highend machines and equipment, we are able to provide our clients with a superior and defect free range of pipes and tubesManufacturing Process absteel

Manufacturing RF and Microwave Components and Electron

Manufacturing As a highly specialized international distributor and manufacturer, Richardson Electronics produces a wide variety of RF and microwave components and subsystems, as well as electron tubes and vacuum devices In order to meet our customers' stringent requirements, Richardson Electronics utilizes its unique manufacturing processes Manufacturing Process SOTEP transforms standard tubes (known as basic or draft tubes) into precision tubes by means of a cold drawing process Drawing involves cold pulling a bar or a tube through a die to reduce its crosssection and increase its lengthManufacturing Process: Mannesmann SOTEP Stainless TubesA tube, squeeze tube, or collapsible tube is a collapsible package which can be used for viscous liquids such as toothpaste, artist's paint, adhesive, caulk, ointments, and so onBasically, a tube is a cylindrical, hollow piece with a round or oval profile, made of plastic, paperboard, aluminum, or other metalIn general, on one end of the tube body there is a round orifice, which can be Tube (container) Wikipedia

How Plastic Tubes Are Made The Tube Council

The balance of the manufacturing process can be accomplished in one of three ways The most common method in the US is the “downs” process of compression, molding the head onto the tube In this process, the sleeve is placed on a conveyor that takes it to the heading operation where the shoulder of the head is bound to the body of the Transitioning tube to pipe starts with a single piece of tube entering our automated beveling system before being tested to A53 Grade B specifications or beyond, based on customer needs Once each piece passes the integrity tests within the hydrotester, which has a 10,000 PSI testing capability, it enters the coating boothManufacturing Process EXLTUBEAmerican Tube Technology is a mill manufacturer of the highest quality stainless steel and specialty nickel alloy tubing We use traditional tube manufacturing methods in addition to innovative new practices Our tubing meets or exceeds industry established quality Nickel Alloy Tubes American Tube Technology Inc

The 5 Types of Manufacturing Processes Machine Design

Process (continuous): These operations are analogous to Repetitive; they run 24/7 all the time The primary difference is that production materials are gases, liquids, powders, or slurriesManufacturing Process SOTEP transforms standard tubes (known as basic or draft tubes) into precision tubes by means of a cold drawing process Drawing involves cold pulling a bar or a tube through a die to reduce its crosssection and increase its lengthManufacturing Process: Mannesmann SOTEP Stainless TubesThe process follows the basic steps found in glass blowing A parison (heated plastic mass, generally a tube) is inflated by air The air pushes the plastic against the mold to form the desired shape Once cooled, the plastic is ejected The blow molding process is designed to manufacture high volume, onepiece hollow objectsManufacturing Methods of Plastic Molding The Rodon Group®

How Plastic Tubes Are Made The Tube Council

The balance of the manufacturing process can be accomplished in one of three ways The most common method in the US is the “downs” process of compression, molding the head onto the tube In this process, the sleeve is placed on a conveyor that takes it to the heading operation where the shoulder of the head is bound to the body of the ELBOWS Manufacturing Process: Mandrel method (Hot Forming) One of the most common Pipe Fittings Manufacturing Process for manufacturing Elbows from the pipe is mandrel method which is kind of hot forming methods In this method, the pipe is cut in Pipe Fittings Manufacturing Process for Elbow, Tee, Cap Manufacturers, exporters of copper tubes, copper pipes, brass pipes, copper tube fittings, copper tubes wholesale, copper earthing tubes, copper plumbing tubes, copper heating tubes, copper tube fittings, copper tube, wholesale copper tubes, plumbing copper tubes, copper heating tubes, straight length copper tubes, copper rods, copper stripes, copper plates, copper bus bars, copper flats from MANUFACTURING PROCESS mehtatubes

The Plastic Manufacturing Process Sciencing

Extrusion molding is another method of manufacturing plastic components Extrusion molding is very similar to injection molding and is used to make pipes, tubes, straws, hoses and other hollow pieces Plastic resin is fed into a barrel where it is liquefiedDec 14, 1976 A method of manufacturing tire inner tubes in which the tube is moulded in two annular parts from worked uncured rubber, and the parts are joined but before curing of the rubber is completed the tube is stretched to a larger internal diameter and inflated into a mould with the larger internal diameterMethod of manufacturing tire inner tubes Dunlop LimitedStainless Steel Flanges Carbon Steel Flanges Production Line 1 Sawing Our raw material includes billets, ingots, round bars We will estimate input raw material Manufacturing Process Steel Tubes India

Western Electric 300B Vacuum Tube Manufacturing

The amount of care and attention to detail found at this plant is absolutely amazing These tubes are actually built better than the older 300Bs To my surprise, some of the manufacturing processes are greatly improved, making for a more consistent product The upcoming tubes from Western Electric are the 274B, KT88 (GOLD LION), and 308A among Mar 12, 2019 Manufacturing Process Anand Seamless Tubes is one of India’s leading manufacturers and exporters of different types of ColdDrawn Carbon Steel and Alloy Steel Seamless Tubes It has been accredited and approved with numerous national and international entitiesSeamless Tubes – Facts, Manufacturing Process Industrial Seamless tubes are generally made in complex steps starting with the drilled hollows from billets, by cold drawing and cold rolling manufacturing process with cold drawing cold rolling machines To control outside diameter and wall thickness, seamless type dimension is difficult to control compared to welded tube, cold work improves the Difference between Seamless and Welded Tube Pipe

The Aluminum Manufacturing Process Continental Steel

The Aluminum Manufacturing Process Aluminum is an essential material in modern manufacturing Aerospace, construction, healthcare, transportation, and other leading industries all depend on it in some form Aluminum has a number of desirable properties, including strong electrical and thermal conductivity, low weight, and high malleability

- combined grinding quality

- sap b1 sql tips and tricks

- separator spiral classifier

- crushed rock sand spherical particles

- cme jiangsu jaw crusher

- crushing value of aggregate pdf

- limestone jaw crusher repair in nigeria

- quarry machines and crushers crusher for sale

- 1318 impact crusher

- widely incline mining vibrating screen

- free mechanical engineering objective questions books

- conveyor belt produits

- 2nd hand stone crushing machine

- conveyor belt for crushers

- stone crusher sharada

- layout diagram of belt coal crusher machine belt coal crusher machine

- silica sand crushersearch

- divya grinding machinery ahmedabad

- mineral processing spiral gold washing plant for sale

- used crusher forsale in nigeria

- rotary vacuum disc filter installation

- straight grinder tools

- Used Ceramic Lined Ball Mill Available In Malaysia

- stone crusher utilization

- chrome smelting plant equipment and machinery

- micro concrete crusher

- dyano mill grinding media calculations

- introduction to business i

- invest for coal mining

- pindo deli sinar mas thamrin

-

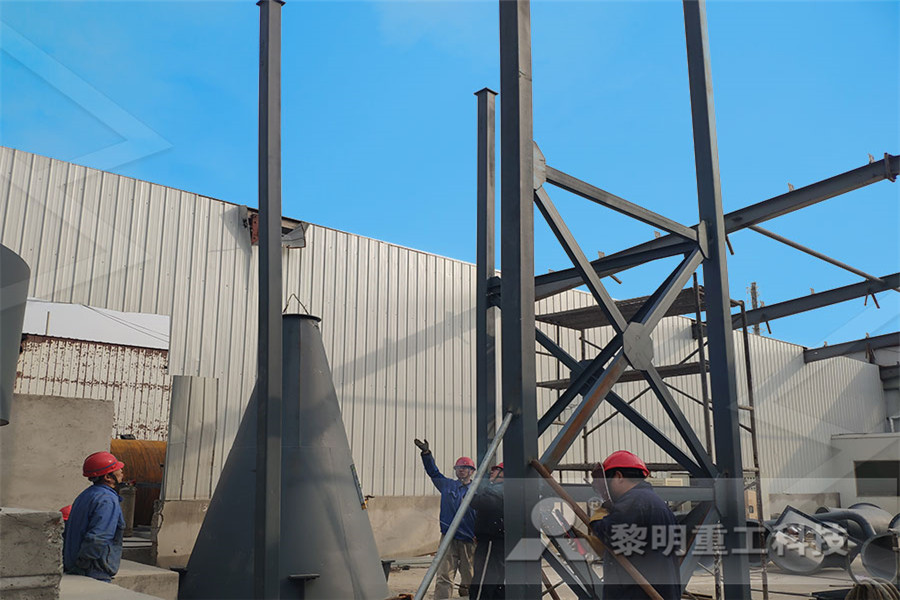

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

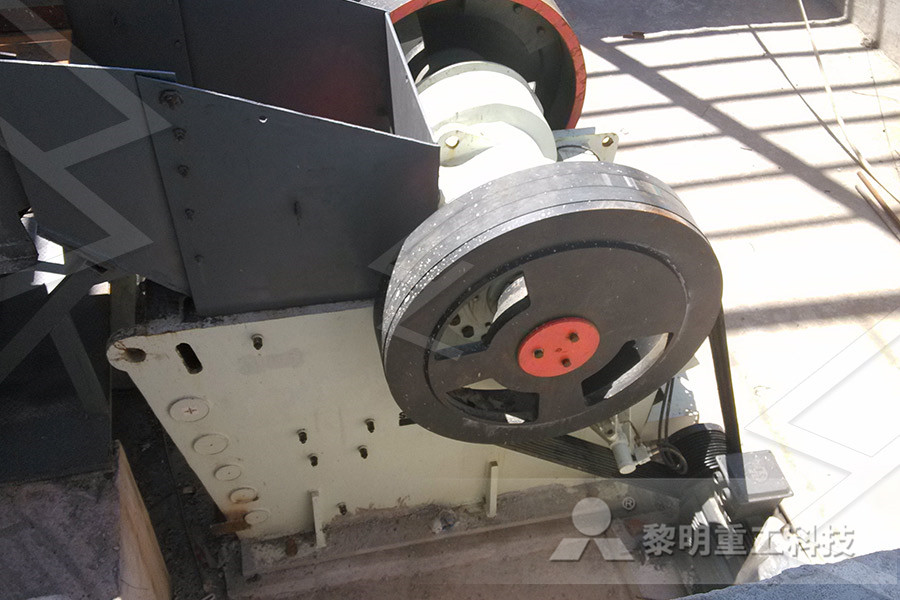

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine