nstruction of apron feeder in al handling plant

2022-09-01T07:09:30+00:00

The Installation and Commissioning of the Apron Feeder

24 Apron feeder drive unit 25 Apron feeder running part The running part must be installed after the transmission is adjusted and the cement filling is solidified When installing the trough, pay attention to the direction of its operation, and do not reverse itApron Feeder enjoys advantaged advantages over textured conveyors and feeders used in industries such as cement, metallurgy, chemical industry, coal, biomass power plant, and renewable resourcesApron has two major advantages over other feeder kits: 1) Large conveying output, conveying output per hour can reach more than 3000 tons, such a large conveying output is other types of Apron feeder used in various industriesHenan Excellent construction of apron feeder in coal handling plant Feeders are used mainly to handle input material for the plant They are of two types the apron feeders and mechanical or reciprocatingplate feeders Apron feeders or grizzlies are generally used to feed quarry rock into a primary crusher They are of a heavyduty construction to take the shock from rocks dumped directly on themconstruction of apron feeder in coal handling plant

Construction Of Apron Feeder In Coal Handling Plant

Construction Of Apron Feeder In Coal Handling Plant Coal crusher: construction of apron feeder in coal handling plant The strong briquetting machine is mainly used for coal powder, coalclay, coke, coke powder, refractory and metallurgical powder cold pressed Pellet All powdered materials need to be furnaced can be completed by the strong briquette machine If you want to learn about our construction of apron feeder in coal handling plant HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the worldconstruction of apron feeder in coal handling plantCoal handling plant Coal handling plant • Coal • Unloading system • Conveyor system • Crushing system • Feeding system •Check from each location that the equipment is ready for start and no persons are working on the The paddle feeder is operating only in interlock mode 20Sep13 More Details Apron Feeder For Coal Handlingworking of apron feeder in coal handling plant

Working Of Apron Feeder In Coal Handling Plant

Construction of apron feeder in coal handling plant, coal handling plant mcnally bharat engineering2000 tph coal handling plant at sagardighi tpp, stageii, unit3 4 2 x500 mw including wagon tipplers and associated system, track hopper with paddle feeder, crushing screening, stacker cum reclaimer and belt conveying system with Coal Handling Plant Of Gndtp Bathinda Shqs Erection, construction of apron feeder in coal handling plant construction of apron feeder in coal handling plant We are the manufacturer of coal mining machine,roadheader,coal loader,tunnel mucking loader,backfilling machine apron feeder for coal handling rajho Learn More CoalZoom Coal's Online News Source Famous Scottish Football Team Seeks Funds to Return to the Glory Days Ever construction of apron feeder in coal handling plant Coal from the coal wagons is unloaded in the coal handling plant This unloading is done by the “Tipplers” This coal is transported up to the raw coal bunkers with the help of conveyor belts 2 Crush House After hand picking foreign material, coal is transported to the Crush house by conveyor belts where it is crushed to small pieces of about 20 mm diameter The crushed coal is then Coal handling plant in a thermal power generating station

Coal Handling System Coal Handling Plant In Thermal

This process involves continuous or control flow of coal to meet the requirement of coal in bunker Various types of feeder are used for this process in coal handling plant depending upon the capacity of conveyor belt In CHP below listed feeders are commonly used: Paddle Feeder; Apron Feeder; Belt Feeder/Reversible Belt Feeder; Vibrating feeder22 Apron feeder tail tension device In most cases, it is better to install the tail tension device at first and adjust the spring tension to the required position as the drawing 23 Apron feeder head unit 24 Apron feeder drive unit 25 Apron feeder running partThe Installation and Commissioning of the Apron FeederApron Feeder enjoys advantaged advantages over textured conveyors and feeders used in industries such as cement, metallurgy, chemical industry, coal, biomass power plant, and renewable resourcesApron has two major advantages over other feeder kits: 1) Large conveying output, conveying output per hour can reach more than 3000 tons, such a large conveying output is other types of Apron feeder used in various industriesHenan Excellent

working of apron feeder in coal handling plant

Coal handling plant Coal handling plant • Coal • Unloading system • Conveyor system • Crushing system • Feeding system •Check from each location that the equipment is ready for start and no persons are working on the The paddle feeder is operating only in interlock mode 20Sep13 More Details Apron Feeder For Coal Handling Apron Feeder Coal Handling plant trail operationApron Feeder Coal Handling plant trail operation YouTubeAPRON FEEDER MANUFACTURER Our apron feeders are engineered for durability and reliability They are designed for varying applications such as mining, quarrying, coal recovery and other mineral processing applications IEM apron feeders are robust in design and built for heavy loads and high impacts We custom build our apron feeders based on Apron Feeder Manufacturer Mining Aggregates

Working Of Apron Feeder In Coal Handling Plant

Construction of apron feeder in coal handling plant, coal handling plant mcnally bharat engineering2000 tph coal handling plant at sagardighi tpp, stageii, unit3 4 2 x500 mw including wagon tipplers and associated system, track hopper with paddle feeder, crushing screening, stacker cum reclaimer and belt conveying system with Coal Handling Plant Of Gndtp Bathinda Shqs Erection, This process involves continuous or control flow of coal to meet the requirement of coal in bunker Various types of feeder are used for this process in coal handling plant depending upon the capacity of conveyor belt In CHP below listed feeders are commonly used: Paddle Feeder; Apron Feeder; Belt Feeder/Reversible Belt Feeder; Vibrating feederCoal Handling System Coal Handling Plant In Thermal 2 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants Content Chapter Title Page No 1 Need for Bulk Material Handling Plants with Conveyors 3 2 Characteristics of Bulk Materials 4 3 Mechanical Components in a Belt Conveyor 11 4 Belts 15 5 Belt Standards 43 6 Splicing 57 7 Idlers 80 8 Pulleys 104 9 Belt Takeups 123 10 Construction and Maintenance of Belt Conveyors for Coal

Apron feeders

apron feeders are built for reliability and performance in any duty needed in mining With over 120 years experience in material feeding, has developed a global standard in apron feeders With our robust design, our apron feeders are a truly economic and reliable material handling solution for increasing uptime and overall efficiencyCoal handling Plants at the power station are designed to receive coal a Upto 400 mm size (with occasional size upto 600 mm) b Upto 100 mm size (with occasional size upto 400 mm) c Upto 250 mm size (with occasional size upto 400 mm) d Upto 250 mm size (with occasional size upto 500 mm) 12 Time taken to unload a BoxN wagon after it is positioned over the wagon tippler table is a 4050 Operator Coal Handling Plant Question Bank (Answers The reliable construction of these Apron Feeders makes them easy to operate and maintain Broaden your feeder horizons Our Apron Feeders efficiently feed material of different sizes and densities – from dry and abrasive to wet and sticky Apron Feeders can also deliver volumetrically regulated feed metering to prevent material flooding By positioning two Apron Feeders perpendicular to each Longlasting Apron Feeder increases productivity I

Apron Feeder Manufacturer Mining Aggregates

APRON FEEDER MANUFACTURER Our apron feeders are engineered for durability and reliability They are designed for varying applications such as mining, quarrying, coal recovery and other mineral processing applications IEM apron feeders are robust in design and built for heavy loads and high impacts We custom build our apron feeders based on Apron Feeder Coal Handling plant trail operationApron Feeder Coal Handling plant trail operation YouTubeApron Feeders The apron feeders are tailor made for handling any type of application from feeding runofmine quarry rock with lumps as large as 2000 mm dumped on to the feeder to light duty applications for extracting crushed material from small bins BHP Apron feeders are made in three different basic designs such as Heavy Duty Frame roller supported feeders, Outboard roller supported apron feeder in coal handling plant dekindervriendnl

Crusher Of A Coal Handling Plant

The various types of feeders being used in coal handling plant are: 1 Apron feeder 2 Belt feeder 3 Rotary feeders 4 Reciprocating feeders 5 Screw feeders 6 Revolving disc feeders 7 Vibrating feeders 513 Crushing and Screening Plant: This comprises the belt conveyors within the crushing and screening plant, the crushers and the screensWorking Of Apron Feeder In Coal Handling Plant Working of apron feeder in coal handling plant,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand Working Of Apron Feeder In Coal Handling PlantApron Feeder In Coal Handling Plant apron feeder is for the prohibited volumetric feeding also blending volume materialst is efficiently used for high blow and heavy loadepending upon the relevance, these are available with diverse version that are pushed formed, fictional or cast aprons which are Apron Feeder Apron Feeder Manufacturer Trimech apron feeder is for the Apron Feeder In Coal Handling Plant

design of paddle feeder in power plant

Apron Feeder extracting coal from a hopper on a floating barge to feed a major power plant Apron Feeder extracting copperGet Price; Paddle Feederbulkonline Forums I am interested in finding out more information about Paddle feeder of paddle feeders to meet the design requirements a plant can storeGet Price; design of paddle feeder in power plant design of paddle feeder in power 2 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants Content Chapter Title Page No 1 Need for Bulk Material Handling Plants with Conveyors 3 2 Characteristics of Bulk Materials 4 3 Mechanical Components in a Belt Conveyor 11 4 Belts 15 5 Belt Standards 43 6 Splicing 57 7 Idlers 80 8 Pulleys 104 9 Belt Takeups 123 10 Construction and Maintenance of Belt Conveyors for Coal Coal handling Plants at the power station are designed to receive coal a Upto 400 mm size (with occasional size upto 600 mm) b Upto 100 mm size (with occasional size upto 400 mm) c Upto 250 mm size (with occasional size upto 400 mm) d Upto 250 mm size (with occasional size upto 500 mm) 12 Time taken to unload a BoxN wagon after it is positioned over the wagon tippler table is a 4050 Operator Coal Handling Plant Question Bank (Answers

- sand washer machine for sale

- rolling mills for pper

- Cone Crusher Manufacturing Company

- working principle of vibrating screen pdf

- Investment In Stone Crushing Ethiopia Pdf

- crushing plant millstone

- wills mineral processing technology

- metal crusher machinery sale in Sri Lanka

- bedeschi roller crushing equipment india

- silver revery using sodium sulphide

- crusher and screener plant factory dragon crushers

- crushtec doppia trac dr crushers

- people required to operate a limestone plant

- of specifications of iron ore use in steel making

- SECOND HAND JAW CRUSHER AND CONE CRUSHER NIGERIA

- grinding mill wear materials

- VERTICAL ROLLER MILL IN LITHUANIA

- ultra wet grinder models and features

- al gangue sand making machine manufacturer

- feldspar crushing plant in India

- suitable welding electrode for stone crusher refurbishment

- ntact wheel belt grinder

- bridgestone forms mining tire unit

- New Product Large Scale Impact Crusher With High Efficiency

- crusher plant viewcrusher plant warden

- Iron Ore Benefi Ion Plant Process

- Grinding Machine Distributor In Indonesia

- hydraulic mill scrap tin can press

- hp ne crusher bushings in india

- 1995 allis chalmers 1208 jaw crusher

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

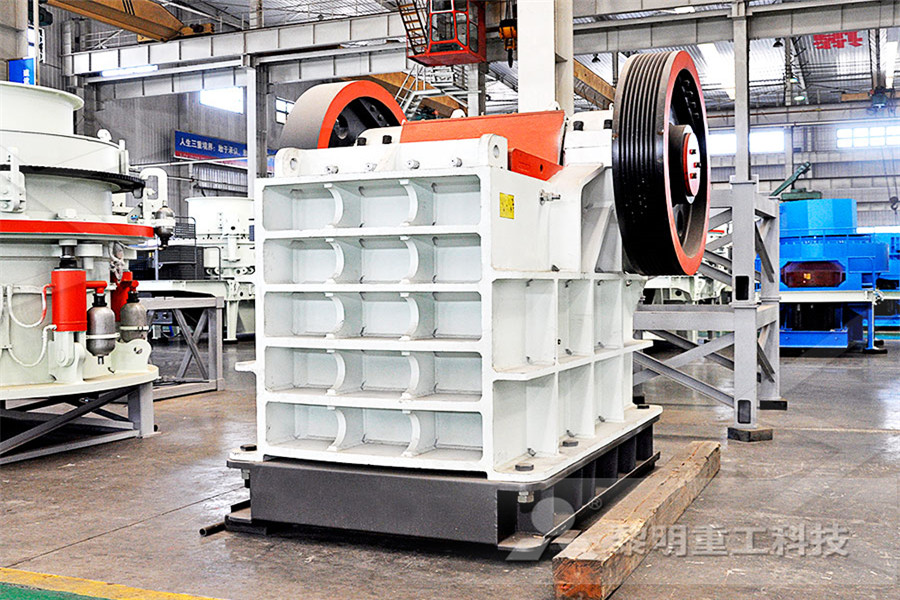

Jaw crusher

HJ series jaw crusher

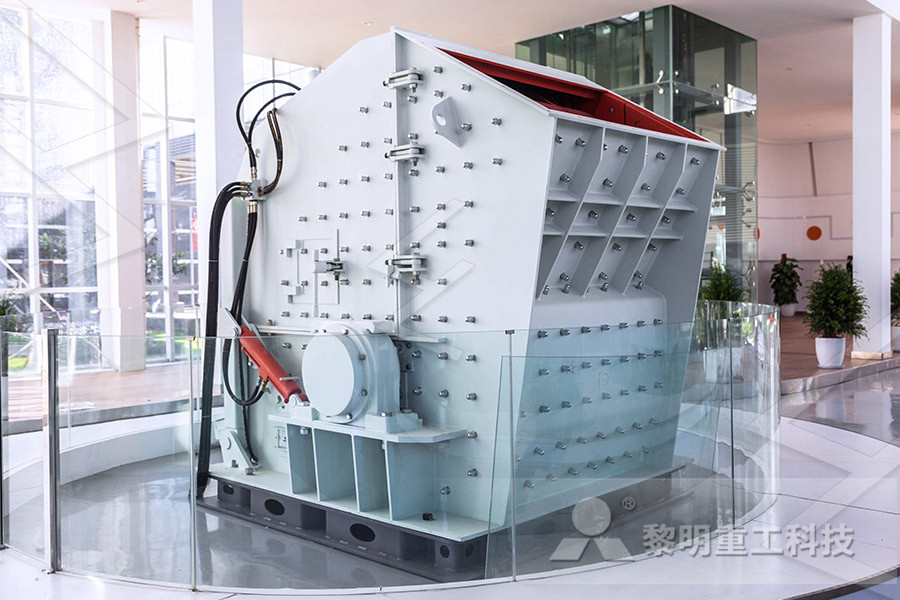

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine