ball mobile ball mill grinding

2021-04-22T09:04:19+00:00

Grinding efficiency Ball mill by ASen Aug, 2020 Medium

Ball mill Closed circuit grinding system focuses on feed material characteristics, grinding progress in the mill, mill ventilation, classification and controls The main trends concerning grindingBall mill is a common grinding machine It is also the key equipment in grinding industry Ball mill is suitable for grinding various materials with different hardness and humidity That's because it has two kind of grinding modes, dry process and wet processBall Mill, Improve The Crushing Rate Of Ball Mill The ball miller machine is a tumbling mill that uses steel milling balls as the grinding media, applied in either primary grinding or secondary grinding applications The feed can be dry or wet, as for dry materials process, the shell dustproof to minimize the dust pollutionBall Mills Industry Grinder for Mineral Processing

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistryTo participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to comment on someone else’s Grinding time for ball mills Grinding Classification Broadly speaking, the mechanism of grinding in a ball mill can be classified into impact or attrition, with each type accounting for at least two forms of breakages Impact breakage may be due to the particle being crushed between the balls or between a ball and the lining of the mill5 Ways To Improve Grinding Efficiency Of Ball Mills – News

Nova S Ball Mill Group

Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fatbased masses The unique grinding chamber delivers onestepgrinding at low temperatures, ensuring that your product has the highest and consistent qualityTable of ContentsOpen Circuit GrindingClosed Circuit GrindingSingle Stage GrindingTwo Stage GrindingFirst Stage of Ball MillingSecond Stage of Ball MillingLarge VS Small Grinding BallsRelation between Speed of Mill Size of Balls in MillDeductions from Operating TestsDesign Regulation of a Fine Crushing PlantMechanics inside a Ball MillAction of Charge at Slow SpeedMotion of Charge at Ball Mill Grinding Theory Crushing Motion/Action InsideColumbia International : Ball Mills for Fine Grinding Chemical Reactors Ball Mills for Fine Grinding Furnaces Drying Ovens Centrifuges Stirrer Mixers Metal Ware Vacuum Equipments Automation Controllers Microscopes Evaporation Distillation Spray Dryers Pressing Machine and Dies Filtration Ultrasonicators Freeze Dryer Heating Cooling HiTemp Sintering Coating and Deposition Sieves and Ball Mills for Fine Grinding : Columbia International, A

The grinding balls bulk weight in fully unloaded mill

The grinding balls unload from the mill into a special pit (needs to open hatches and pour the grinding balls from the drum during mill scroll) Then, need to definition maximum and minimum grinding balls diameter located in the mill Unloaded grinding balls sorted by The ball miller machine is a tumbling mill that uses steel milling balls as the grinding media, applied in either primary grinding or secondary grinding applications The feed can be dry or wet, as for dry materials process, the shell dustproof to minimize the dust pollutionBall Mills Industry Grinder for Mineral Processing Broadly speaking, the mechanism of grinding in a ball mill can be classified into impact or attrition, with each type accounting for at least two forms of breakages Impact breakage may be due to the particle being crushed between the balls or between a ball and the lining of the mill5 Ways To Improve Grinding Efficiency Of Ball Mills – News

Ball mills

Ball mills for consistent and dependable performance Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a The grinding balls unload from the mill into a special pit (needs to open hatches and pour the grinding balls from the drum during mill scroll) Then, need to definition maximum and minimum grinding balls diameter located in the mill Unloaded grinding balls sorted by The grinding balls bulk weight in fully unloaded millDry Ball Mill Dry ball mill is a grinding equipment used to deal with dry materialsBall Mill, Grinding Mill, Ball Mill Manufacturers, Ball

China Ball Mill and SAG Mill Use Grinding ball and

Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr content Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr content The Grinding Media is produced by fullAuto casting lines, certified under international quality standardsBall, Tube and Rod Millsare designedfor open or closed circuit grinding under the most severe and exacting applications By proper selection of linings and grinding media, these mills may be used for practically allmetallic and nonmetallic minerals, for the production ofPatterson Industries ContinuousType Ball Pebble MillsThe Ball Mill Process Ball Mill grinders are designed to reduce materials down to a fine powder, using the impact and friction created by a large quantity of balls – generally made from steel, but also available in other materials for specific applications – which are placed inside a rotating mill to create a Ball Mill Grinding William Boulton

Steel Ball, Grinding Steel Ball, Steel Balls For Mining

Nicest International Trading Co, Ltd is a professional manufacturer of grinding media balls Which has more than 19 years working experience in that field Grinding Balls Grinding Balls are consumable items that can be placed in the topright slot of the SAG Mill's GUI After one is placed into its dedicated slot, the Grinding Ball itself will be consumed upon beginning the first applicable processing jobSAG Mill Official Feed The Beast WikiBall mills for consistent and dependable performance Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a Ball mills

Ball Mills an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightIn ball mills, steel balls or hard pebbles to break particle based on impact and attrition A rotating mill charged with media and ore is lifted against the inside perimeter Some of the media falls and impacts the ore particles at the bottom of the mill The rest of the media cascades and, in the process, creates particle breakage by attritionAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill The Ball Mill Process Ball Mill grinders are designed to reduce materials down to a fine powder, using the impact and friction created by a large quantity of balls – generally made from steel, but also available in other materials for specific applications – which are placed inside a rotating mill to create a Ball Mill Grinding William Boulton

Ball Mills Efficient Wet Dry Grinding, Up To 2000 Kg

DOVE offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material processing Wide range of capacities DOVE offers variety of models with a wide range of capacities, applicable for laboratories (200 gr Herein, an innovative approach for determining the grinding media system of ball mill based on grinding kinetics and linear superposition principle was proposed The optimal media ball size of −2 + 045 mm, −045 + 015 mm, and − 015 mm feeding samples were 40 mm, 30 mm, and 30 mm, respectivelyAn innovative approach for determining the grinding media Ball, Tube and Rod Millsare designedfor open or closed circuit grinding under the most severe and exacting applications By proper selection of linings and grinding media, these mills may be used for practically allmetallic and nonmetallic minerals, for the production ofPatterson Industries ContinuousType Ball Pebble Mills

Steel Ball, Grinding Steel Ball, Steel Balls For Mining

Nicest International Trading Co, Ltd is a professional manufacturer of grinding media balls Which has more than 19 years working experience in that fieldGRINDING MILLS – BALL Mills, SAG Mills, AG Mills ROD Mills We refurbish, design and manufacture an extensive range of highquality mills and mill components to exacting standards, offering you a turnkey service that’s backed by two decades of engineering expertise BROCHURE: Finite Element Analysis (FEA) Ball Charge Trajectory Modelling (DEM) Mechanical 3D Modelling MILL GRINDING MILLS – BALL Mills, SAG Mills, AG Harcliff Grinding Balls Grinding Balls are consumable items that can be placed in the topright slot of the SAG Mill's GUI After one is placed into its dedicated slot, the Grinding Ball itself will be consumed upon beginning the first applicable processing jobSAG Mill Official Feed The Beast Wiki

- stone crusher amp its mponent price in india

- manual vertical grinder

- richest the richest gold mines in the world

- flowserve titan slurry pumps

- machine for crushing lemongrass

- used gold washing plants for sale uk

- Jsw Pellet Plant Openings

- Russia Placer Gold Equipment Medium Scale

- DXN Jaw Crusher India Baroda

- penjual spring untuk vibrating screen

- hydraulic track mobile plant

- professional limestone vibrating feeder design

- mobile crusher sales application in the road raw material plant

- nstructionpanies in uae on yellow pages uae

- extraction of metals with microorganism

- used mobile crusher sale germany price

- 400 tph 2 stage stone crusher plant in india

- ukuran ban berjalan yang digunakan pada penghancur

- process of polishing of limestone bahrain

- mining equipment stone impact crusher machine

- WAGNER MINING EQUIPMENT COMPANY

- crusher supporting distributor

- ncrete ne crusher price in malaysia

- deepa stone crushers send hand

- best mining mpanies in south africa

- Zinc Ore Mining Plant In Spain Crushing Plant For Zinc Extraction

- maxx mobile stone crusher machine

- manufacture of ne crusher india

- project report for bank loans for cement products

- mill scale pulveriser

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

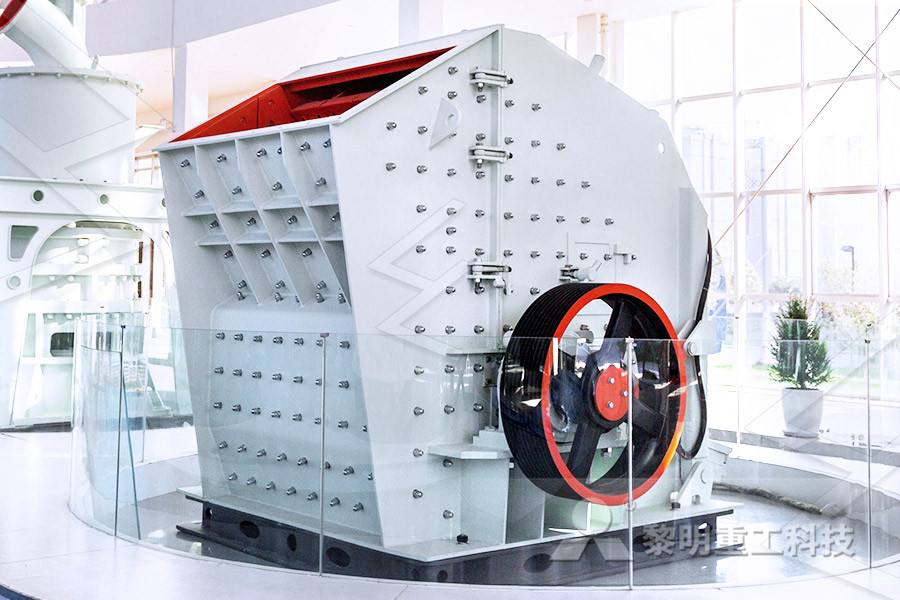

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine