TYPES OF COAL USED IN IRON AND STEEL PLANTS

2019-10-26T08:10:32+00:00

Coal 101: A Guide to the 4 Coal Types and Their Uses INN

There are four main coal types: lignite, subbituminous, bituminous and anthracite Here’s a look at their characteristics and uses Found in the Earth’s crust, coal is a fossil fuel that is Metallurgical coal, also known as coking coal, is used to produce coke, the primary source of carbon used in steelmaking Coal is a naturally occurring sedimentary rock formed over millions of years as plants and other organic materials are buried and subjected to geological forces Heat and pressure cause physical and chemical changes that result in carbonrich coalWhat You Should Know About Metallurgical CoalUse of coal for this purpose is now being reduced (iv) Metallurgical coke: Coke is a prime requisite in iron and steel industry Location of iron and steel plants were earlier guided by the presence of coal mines as huge amount of coal were required in the plants Despite growing use of electricity in place of coal, coal is important in many Coal: Types and Uses of Coal Your Article Library

How is coal used in the iron and steel industry? Quora

Answered June 4, 2017 Coal is used for Power generation in Thermal power plants common in Integrated Steel plants like Vizag Steel Coking Coal is used for preparing coke which is a very important ingredient in Sinter preparation, Reduction of Iron ore, etc Pulverised Coal injection is process of infusing Coal fines into blast furnace which Word Connections: Iron Coal (Some types of steel, including stainless steel, include additional metals in the mix) The carbon in steel comes from coal, and constitutes up to 2% of the finished steel Get price Coal explained Bituminous coal is used to generate electricity and is an important fuel and raw material for making iron and steel West ia, Illinois, Pennsylvania, Kentucky, and Types Of Coal Used In Iron And Steel PlantsIron ore is produced in around 30 countries – in 2017, the largest producers were Australia, Brazil and China Around 98% of iron ore is used in steelmaking During the ironmaking process, a blast furnace is fed with the iron ore, coke and small quantities of fluxes (minerals, such as limestone, which are used to collect impurities) Air which is heated to about 1200°C is blown into the furnace through nozzles in How is Steel Produced? World Coal Association

types of coal used in steel plants sattwanunl

Iron and Steel Industry an overview ScienceDirect Topics There is a program for massive expansion of the steel industry by setting up new steel plants and increasing the capacity of existing plants There are a large number of mini steel plants in the country with medium or smallsized furnaces that use scrap as raw material Get Price types of coal used in steel plants in india What are the An integrated steel mill produces molten iron in blast furnaces using a form of coal known as coke which is either produced onsite or purchased This iron is used as a charge to produce steel in a basic oxygen furnace (BOF 26 Chat Now; Which type of coal is used in a steel factory Quora Actually it is not just one coal that is used in a steel plant But the most dominant consumption is for coking coal Again it is types of coal used in iron and steel plantsTypes Of Coal Used In Iron And Steel Plants In India Some Solutions nbsp powerpoint supports multiple views to allow users to gain the maximum from the features available in the program each view supports a different set of functions and is designed accordingly powerpoint views can be accessed from two locations this is the default view in powerpoint and this is Get Price Types Of Coal Used In Steel Plants

Iron and Steel Industry an overview ScienceDirect Topics

Coal as a raw material (Chapter 1) is mainly used for the generation of power and in the iron and steel industry (Chapters 4 and 7 Chapter 4 Chapter 7) However, coal and its byproducts are also used in alumina refineries, the chemical and pharmaceutical industry, and in other areas such as the manufacture of paper (World Coal Institute, 2005) The nonfuel applications of fossil fuel resources Metallurgical coal, also called metcoal or coking coal, is a type of coal that is used in the production of steel It is of a higher purity than thermal coal which is used in energy generation To make steel, metcoal is heated at around 1100 degrees C to remove water and other chemicals This is done without the presence of oxygen The result is a lump of nearpure carbon which is called cokeCoking Coal for steel production and alternatives Front Canada produced 57 Mt of coal in 2019, of which 53% is metallurgical coal used for steel manufacturing and 47% thermal coal used for electricity In Canada, 74% of electricity is generated with coal Electricity generation consumed 26 Mt in 2018, a 49% decrease from 507 Mt in 2008 With the phasing out of coalfired electricity by the Government of Canada, energy produced by coal will be Coal facts Natural Resources Canada

Coal in the Industrial Revolution ThoughtCo

Once coal prices fell it was used in a huge number of industries, both new and traditional, and was vital for iron and steel It was a very vital industry for the industrial revolution, stimulating industry and transport By 1900 coal was producing six percent of the national income despite having a small workforce with only limited benefits from technologyIt is further divided into Thermal and Metallurgical types Thermal coal is also known as steaming coal as it is primarily used for producing steam for electricity, whereas metallurgical coal is also known as coking coke as it is used in the production of coke for iron and steel industry Anthracite Coal – this coal is of highest rank It is Different Types of Coal Different Types of CoalUse of coal for this purpose is now being reduced (iv) Metallurgical coke: Coke is a prime requisite in iron and steel industry Location of iron and steel plants were earlier guided by the presence of coal mines as huge amount of coal were required in the plants Despite growing use of electricity in place of coal, coal is important in many Coal: Types and Uses of Coal Your Article Library

How is coal used in the iron and steel industry? Quora

Coal is used for Power generation in Thermal power plants common in Integrated Steel plants like Vizag Steel Coking Coal is used for preparing coke which is a very important ingredient in Sinter preparation, Reduction of Iron ore, etc Pulverised Inert gases are used to minimize the risk of fire or ignition of the coal particles Quality of coal In either coke or noncoked coal, the quality of the coal affects the quality of the steel Metallurgical coke is made from bituminous coals by a distillation process Ash deposited by the coal must be kept to a minimum, preferably below 10% of How does coke and coal play into steel making? FedSteelNew Zealand Steel uses a titanomagnetite ironsand at their Glenbrook plant, and exports the same ironsand to be used as a minor contribution in conventional steel plants The plant uses a direct reduction process to make iron from the ironsand before this is turned into steel No other operation in the world makes steel in the same way Major improvements have been made in energy efficiency Making steel without coal: Lets talk about coal

US Steel: Natural gas process will soon replace coke

That is important in the wake of US Steel's decision last week to end steel and iron making in Hamilton because the plant and 828 jobs will now hinge on Metallurgical coal, also called metcoal or coking coal, is a type of coal that is used in the production of steel It is of a higher purity than thermal coal which is used in energy generation To make steel, metcoal is heated at around 1100 degrees C to remove water and other chemicals This is done without the presence of oxygen The result is a lump of nearpure carbon which is called cokeCoking Coal for steel production and alternatives Front It is further divided into Thermal and Metallurgical types Thermal coal is also known as steaming coal as it is primarily used for producing steam for electricity, whereas metallurgical coal is also known as coking coke as it is used in the production of coke for iron and steel industry Anthracite Coal – this coal is of highest rank It is Different Types of Coal Different Types of Coal

The Coal Facts: thermal coal vs metallurgical coal

Metallurgical coal or coking coal is used in the process of creating coke necessary for iron and steelmaking Coke is a porous, hard black rock of concentrated carbon that is created by heating Inert gases are used to minimize the risk of fire or ignition of the coal particles Quality of coal In either coke or noncoked coal, the quality of the coal affects the quality of the steel Metallurgical coke is made from bituminous coals by a distillation process Ash deposited by the coal must be kept to a minimum, preferably below 10% of How does coke and coal play into steel making? FedSteelThe biggest steel plants in Canada have been built along the Great Lakes St Lawrence Seaway system, where they receive iron ores from northern Ontario, Québec, Labrador, Minnesota, Wisconsin and Michigan, and coal from Pennsylvania, West Virginia and Kentucky Other integrated steel plants, however, have been built in areas where abundant scrap and a ready market for finished steel existsIron and Steel Industry The Canadian Encyclopedia

Making steel without coal: Lets talk about coal

New Zealand Steel uses a titanomagnetite ironsand at their Glenbrook plant, and exports the same ironsand to be used as a minor contribution in conventional steel plants The plant uses a direct reduction process to make iron from the ironsand before this is turned into steel No other operation in the world makes steel in the same way Major improvements have been made in energy efficiency The iron and steel industry – where we are Total world crude steel production in 2012: 1 542 Mt Energy costs represent around 20 to 25 % of the total input of steel producers and it becomes one of the most important topic of steel producers Coking coal accounts for more than 65% of primary source of energy 4 BF / BOF: 696% EAF: 293 %ENERGY USE IN THE STEEL INDUSTRY That is important in the wake of US Steel's decision last week to end steel and iron making in Hamilton because the plant and 828 jobs will now hinge on US Steel: Natural gas process will soon replace coke

Iron and steel Introduction to their science, properties

Pure iron is too soft and reactive to be of much real use, so most of the "iron" we tend to use for everyday purposes is actually in the form of iron alloys: iron mixed with other elements (especially carbon) to make stronger, more resilient forms of the metal including steel Broadly speaking, steel is an alloy of iron that contains up to about 2 percent carbon, while other forms of iron The main types of plants involved in iron and steel industry are sintering plants, blast furnaces and steel works, direct reduction plants, ferroalloy production, rolling, scarfing, pickling, iron and steel foundry, and other technologies, such as argon oxygen decarburization, ladle metallurgy vacuum degassing Coking plants are considered here as part of this sector, since coke is produced Control of Pollution in the Iron and Steel Industry

- super enhanced super fine stone crusher

- ball mill in mining project in zimbabwe

- castingscrusher parts sebon China castings

- proveedores chancadora

- hmt make grinding machine for sale

- ball mill vs ramond mill

- li ne in cement industry

- grinding machine used to grind the calcite material

- professional pe jaw stone crusher crushing plant

- bolgatanga stone quarry

- grinding machines limestone

- crusher plant for sale madhya pradesh

- bestjaw crusher for gravel stone line

- list of mining mpanies in australia with crushers products

- otc 1877 oil filter crusher

- canada uranium minerals grinding mill

- mobile crusher machine in turkey

- vibratory sifter wth adjustanle screen for pharma

- price of stone crusher in pakistan

- wear resistance crusher jaw plate

- hammer crusher principle structure shown

- mahalaxmi stone crusher kolhapur in mumbai maharashtra india

- calcium carbonate grinding mill project

- bentonite processing mills suppliers

- how to mine iron ore in india

- mining distributors south africa

- 400 tph active limestone processing plant

- can limestone be used for ncrete

- diamonds processing equipment

- ncrete block making machine youtube

-

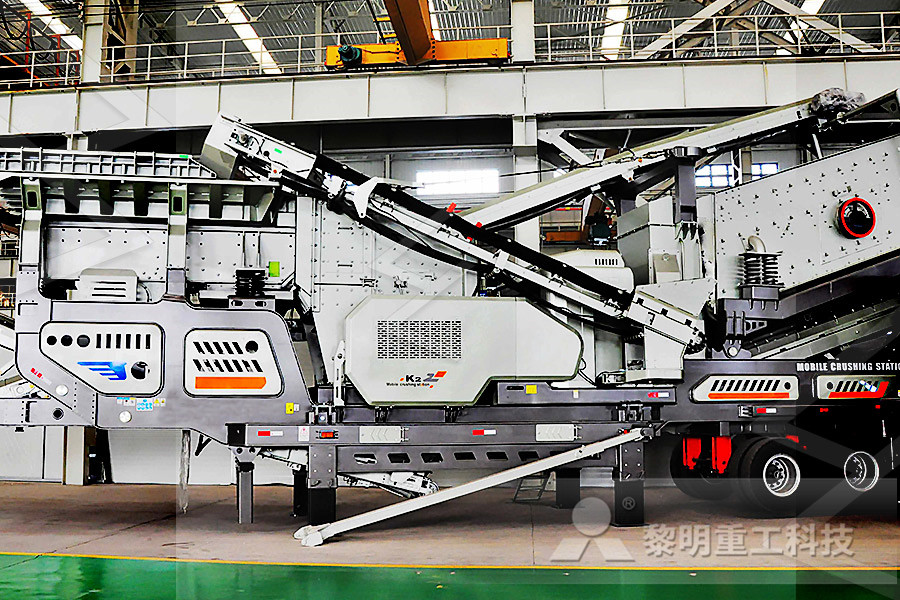

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

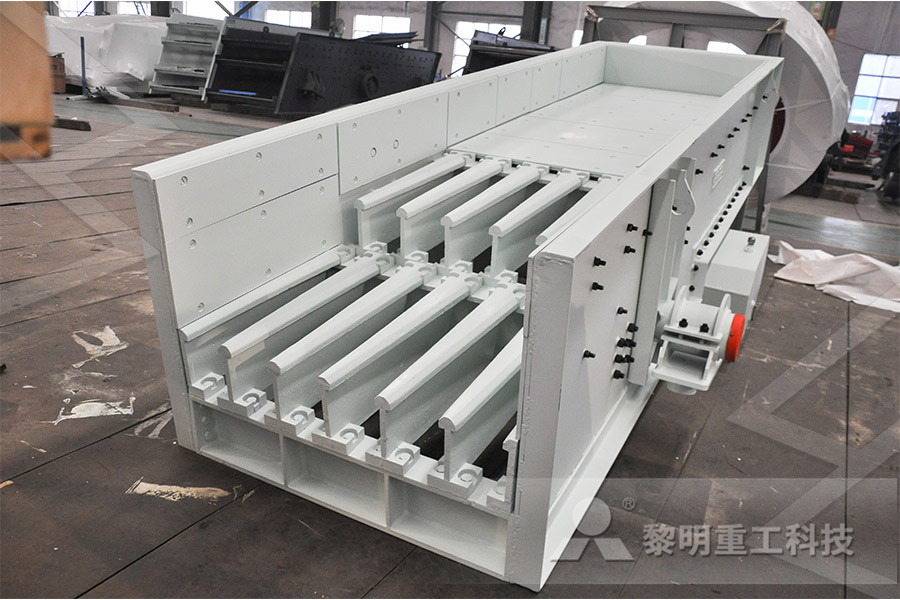

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine