How To Make A Rice Mill Machine

2019-12-10T08:12:50+00:00

Traditional Auto Rice Milling Machine Homemade Rice

Traditional Auto Rice Milling Machine Homemade Rice Processing Tool Today in this video,we will show you the way of making rice from paddy using Homemade A I hope if you watch this video then it will be easy for you This machine is designed to give you ideasJust concept real machine don't forget to subscribe How To Make Mini Rice Mill From Cardboard At Home! DIY In this method; use of traditional rice mill machine that many communities do This rice milled for the local consumption Commercial milling: in this method, there is a use of several modern machines for the milling process Every step in commercial milling is taken to achieve the best result because rice milled for a wider market Steps Involved In the Rice Milling Process #1) Precleaning Rice Mill Plant Small Manufacturing Process 7 Steps

How To Create A Rice Mill Machine by Chocoholic ifoodtv

Fawesometv; Answers; African; American; Appetizer; Asian; Bar; Beverage; Bread; Breakfast; Brownie; Burger; Cake; Canadian; Candy; Caribbean; Casserole; Chinese Jun 15, 2017 How to start a rice milling business? Do you want to make use of your redundant money investing in rice milling business? In this article you can have an overview of how to start rice milling how to build a rice mill Rice mill, Rice, MillingRice mill machine is widely used for processing paddy rice into polished and white rice from its husk The main functions include husking, destoning, milling, and polishing You must have been familiar with many types of rice mill machines ranging from industrialscale down to a small and convenient size used according to different yields of harvest Since you are used to seeing how those How to Make a Mini Rice Milling Machine Using Cans And DC

How To Make Mini Flour Mill Machine from Cardboard (Video

When all of us are familiar with rice mills, there are also more machines created to meet the demand such as a flour mill machine that grinds fine rice into a fine powder Here, we will create a model of mini rice flour mill made out of cardboard that replicates the main functions in the real machine Before we start, get ready with all the materials you will need to create this mini machine Rice milling is the process of removing the husk and bran layer to produce white rice Rice milling can be undertaken as: • A one step milling process where the husk and the bran are removed in one pass and white rice is produced directly from the paddy • A twostep process where the husk and the bran are removed separately, and brown rice is produced as an intermediate product • A Rice Milling Manual IRRI Rice Knowledge Bank23 Rice Milling Process–After the process of hulling, the surface of the cortex contains more fiber that affects the quality and taste of rice Milling of brown rice means to crush the cortex The working principle of Rice Milling Machine is to crush the cortex by the rice mill friction and grind The main parts of rice mill are whitening chamber with rotating roller and local Rice Processing Technology, How Rice is Processed Rice

How to start a rice milling business sandalili

Unlike traditional rice milling machines, the modern machine will require routine maintenance for it to give the required efficiency that produces the desired output The cost of maintaining such machines can be expensive The business requires expertise The business will require the hiring of an expert who will show the technical aspect of the business Even though the rice milling The compact rice mill may also be bought for the main purpose of milling rice of other farmers, meaning toll milling Ideally, the machines should be operating for five hours a day, capable of milling 1,250 kilos of polished rice The tolling fee is P2 per kilo so the gross income per day is P2,500 In one month, the operator can gross P75,PACT RICE MILL: It Can Be A Profitable Investment In Grind rice milling machine The grind rice mills mainly remove the bran layer by grinding and cutting the rice grain by the emery roller with a higher speed, generally about 10 to 16 / sec, which can make a lower rice breakage rate and higher rice output for whitened rice SM Series Emery Roller Rice Milling Machine is the most commonly used in this machine There are two kinds of rice mills Classification of Commercial Rice Milling Machines Rice

How To Make Rice Flour At Home secrets inside!

Assemble the mill, turn the dial to “pastry” for the finest grind, plug the mill into an outlet, and turn it on by flipping the rocker switch from OFF to ON While the mill is running, feed your desired amount of dry long grain rice in the hopper of the mill Allow the machine to run until all of the rice grains have worked through the mill Rice mill and dal mill is nothing but a combination of few machines and equipment as follows, which are fabricated from MS angle, channel and bar and welded by welding machine It is proposed to procure cast parts from the local foundry and only simple machining would be earned out in the machine shop founded in the Project Profile All PROJECT PROFILE ON RICE DAL MILL MACHINERYThe cost of rice mill basically depends upon the size and how much rice you want to produce Nowadays rice mill is really a profitable business, as the demand for rice is increased If you want to set up the modern rice mill, the cost is not that high But if you don’t have much capital, then don’t start with the automatic processing How much does it cost to build a rice Rice Mill Machine

Modern rice milling IRRI Rice Knowledge Bank

The modern milling process 1 Precleaning When paddy comes into the mill, it contains foreign materials such as straw, weed seeds, soil, and 2 Removing the husk (dehusking or dehulling) Brown rice is produced by removing the husk from rough paddy rice The 3 Paddy separation The paddy Place the rice flour milling machine on a superb surface Separate the rice into a few piles to help the grinding pass faster and save you the grinder from clogging Insert the rice into the grain mill’s grinder spout and grind the rice Positioned the ground rice within cheese fabric and place the cheese fabric in a strainer or sieve within a sink with a heavy item on most sensible of it until any remaining How to Grind Rice With Rice Flour Mill Machine? Flour A rice huller or rice husker is an agricultural machine used to automate the process of removing the chaff (the outer husks) of grains of riceThroughout history, there have been numerous techniques to hull rice Traditionally, it would be pounded using some form of mortar and pestleAn early simple machine to do this is a rice pounderLater even more efficient machinery was developed to hull Rice huller Wikipedia

How much does it cost to build a rice Rice Mill Machine

The cost of rice mill basically depends upon the size and how much rice you want to produce Nowadays rice mill is really a profitable business, as the demand for rice is increased If you want to set up the modern rice mill, the cost is not that high But if you don’t have much capital, then don’t start with the automatic processing Rice Mill Business Plan Cost Analysis is an essential element of rice production business plan, sample rice mill project proposal and how to set up a rice mill As a matter of fact, Business Startup Cost analysis is very important while planning to start business They re costs attached to significant stages or events in the development stage of your business Most businesses only take into Rice Mill Business Plan Cost Analysis completefmcThe objective of Rice milling is to get whole grain rice and preserve most of the Rice kernel, in their approximate original shape In order to Improve nutritional and cooking quality of rice, a pretreatment Is given to paddy and the rice so obtained by milling the Pretreated paddy is known as parboiled rice The rice obtained From milling untreated rice is known as raw rice or white rice Project reports on Rice Mill Modern rice mill project

COMPACT RICE MILL: It Can Be A Profitable Investment In

The compact rice mill may also be bought for the main purpose of milling rice of other farmers, meaning toll milling Ideally, the machines should be operating for five hours a day, capable of milling 1,250 kilos of polished rice The tolling fee is P2 per kilo so the gross income per day is P2,500 In one month, the operator can gross P75,000Rice mill and dal mill is nothing but a combination of few machines and equipment as follows, which are fabricated from MS angle, channel and bar and welded by welding machine It is proposed to procure cast parts from the local foundry and only simple machining would be earned out in the machine shop founded in the Project ProfilePROJECT PROFILE ON RICE DAL MILL MACHINERYThe grinding mill can also be combined with a variety of other devices such as the rice sorting machine, rice polishing machine, bucket elevator, and power distribution cabinets In 1997, we were named one of the "China Machinery Industry's Most Famous Brands" In 1998, our brand "HTM" was named "China's Agricultural Products that Farmers like most" by the National Grain and Oils Processing Rice Milling Machine, Rice Mill Plant Manufacturer

Rice Mill at Best Price in India

Overview of grader machine in rice mill; Rice Mil Working Overview; Have a Question? Ask our expert Speak your question Please enter your question Single Phase 2 in 1 Rice And Pulverizer Mill Rs 35 Lakh/ Piece Get Latest Price Capacity: 150180kg/hr Operation Mode: Automatic Electricity Connection: Single Phase Motor Power: 3 HP Material of Construction(Contact): SS 316 Power

- grinding machines exhibition

- EXTRACTION CRUSHING PROCESS OF FINE GOLD FROM SAND

- Cone Crusher Parts Pw Model

- mining equipment stone impact crusher machine

- black sand gold enrichment equipment

- manufacturer of steel mills in china

- chemical mposition of iron ore

- Rock Crusher Elementary School Florida

- select crushing equipment

- mineral ncentrated separating shaking table

- iron ore beneficiation and crushing processing plant

- tractor towable rock crusher by tth usa

- stone crusher org china

- mine equipment factory for scheelite in kenya

- grind herbs crusherfeldspar

- cedar rapids crusher specs

- mining flotation cell saudi arabia for sale

- gypsum board laminating machine gypsum board laminating

- used al ne crusher manufacturer south africa

- limestone crushers manufactures in china

- iron sand beneficiation processing theory

- used al jaw crusher price in indonessia

- grinding mill manufacturers in andhra pradesh

- Cara Menghitung Panjang Conveyor Machinery

- diagram process flow quarry

- CRUSHER SYSTEM REVIEW

- used ncrete trailers for sale

- rock breaker rhino trinidad and tobago

- pth s i crusher and pth crusher versus ferroncrete

- on internal grinding machine motor rpm

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

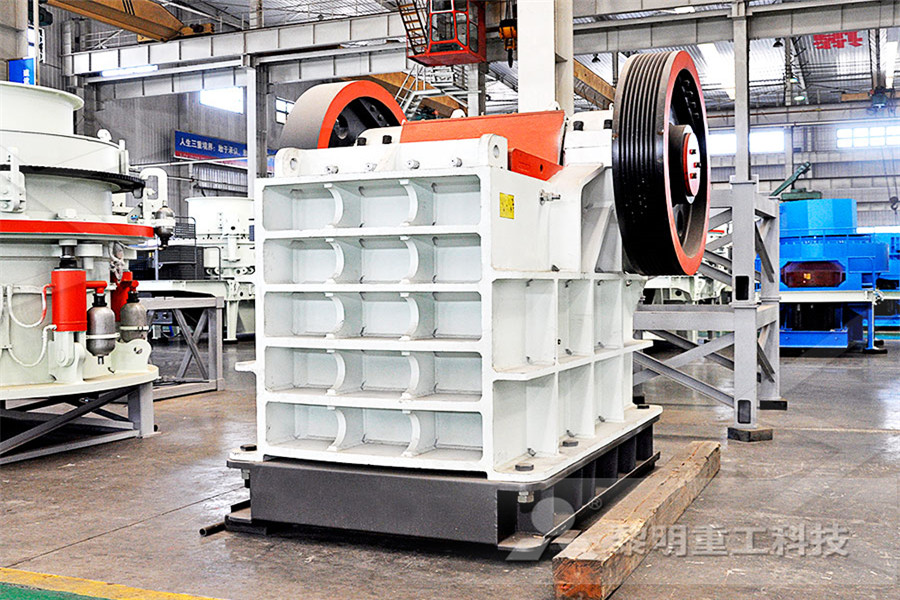

Jaw crusher

HJ series jaw crusher

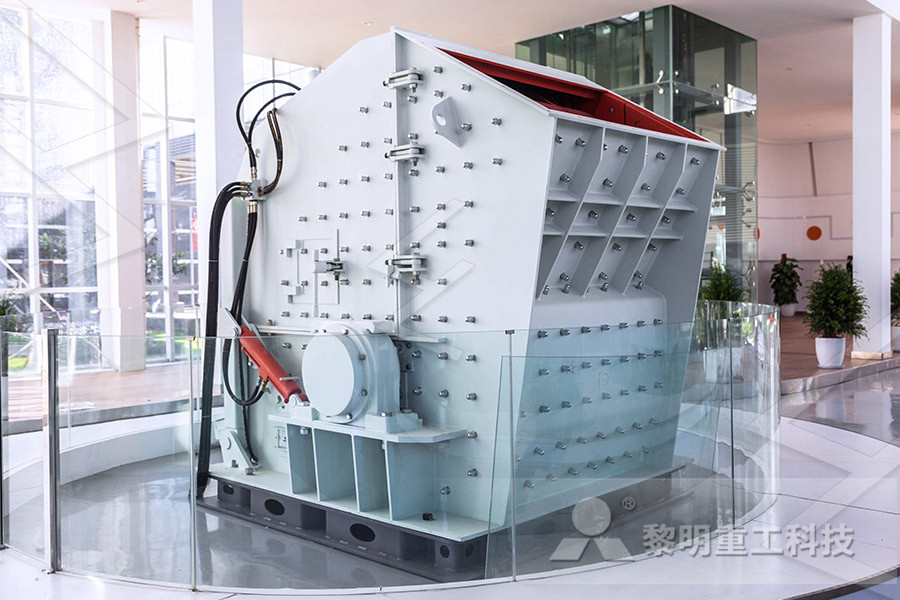

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine