technical ceramic milling ampampamp grinding

2022-07-27T05:07:02+00:00

Ceramic Milling Grinding Precision Ceramics

Ceramic Milling Grinding Machining most technical ceramics is a difficult task due to their incredible hardness and highbrittleness In order to consistently produce highquality ceramic components at reasonable costs you must have the correct machining tools, indepth material knowledge, proper ceramic manufacturing C Ceramic Milling Grinding Machining most technical ceramics is a difficult task due to their incredible hardness and highbrittleness In order to consistency produce highquality ceramic components at reasonable costs you must have the correct machining tools, indepth material knowledge, proper ceramic manufacturing designTechnical Ceramic Milling Grinding Precision CeramicsTechnical Ceramic Machining Grinding Precision Ceramics has extensive experience with hightolerance technical ceramic milling, grinding and polishing of unfired (‘green’) and fired ceramics Our stateoftheart equipment allows us to offer a variety of technical ceramic services including: Ceramic Milling GrindingTechnical Ceramic Machining Grinding Precision Ceramics

Company Tech Ceramic

Ceramic Machining: g rinding, polishing, lapping, 3 axis 5 axis machine, YAG laser, multiwire saw; Analysis and inspection: scanning electron microscope, roughness tester; Innovation Many of our ceramic products came out in the results of our cooperation with first class universities This relationship continues today as we continue with technical ceramic milling amp amp grinding technical ceramic milling amp amp grinding technology courses tech university of northern iowa, theory of metal machining, cuttingtool technology, turning and related operations, drilling and related operations, milling, grinding and other bjt and fet transistors, smallsignal amplifiers Ceramic machining GPOgov , different aspects of technical ceramic milling ampamp grindingThe machining of technical ceramics in an unfired state is called, quite simply, ‘green machining’ and in the case of some of the hardest ceramics, it is a far more economical route to take than post machining after firing In a typical process, a technical ceramic in powder form is mixed with an organic binder and then pressed at very high pressure into a preengineered mold to form a raw Green Machining Precision Ceramics

Technical Ceramic Cnc Milling Amp3BAmp Grinding

technical ceramic milling amp amp grinding technical ceramic milling amp amp grinding Grinding R B Grinding Company Inc founded in 1958 is an ISO 9001 2015 certified manufacturer offering close tolerance machining to large OEM manufacturers Our 140 000 square feet of manufacturing space features state of the art Milling Turning Grinding fabricating assembly and Since 1947 Insaco has been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartzWe machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricityOur customers typically have a critical application that requires extremely tight tolerances in Insaco Inc Ceramic Machining of Hard Materials 70 Machining Grinding on a VMC Likes: 2 Post # ; Post # Results 1 to 13 of 13 I worked in the technical ceramics industry for almost about decade, all using converted standard mills and lathes (until DMG came out with their ultrasonic machines specific for the purpose) and would advise against any repeated grinding on a metal cutting mill There are way too Grinding on a VMC Practical Machinist

ceramics ceramics grinding machinery

Ceramic Milling Grinding Machining most technical ceramics is a difficult task due to their incredible hardness and highbrittleness In order to consistently produce highquality ceramic components at reasonable costs you must have the correct machining tools, indepth material knowledge, proper ceramic manufacturing designCeramic Machining: g rinding, polishing, lapping, 3 axis 5 axis machine, YAG laser, multiwire saw; Analysis and inspection: scanning electron microscope, roughness tester; Innovation Many of our ceramic products came out in the results of our cooperation with first class universities This relationship continues today as we continue with Company Tech CeramicGreen machining of ceramics is done whenever possible since the machining of ceramics after firing is very costly The machining centers found in our plant are very similar to those found in standard machine shops; mills, and lathes drilling equipment, cutoff saws, surface grinders, rotary grinders, as well as many machines that have been custommade inhouse However, the extremely Technical Ceramics Green Machining Superior Technical

Kadco Ceramics Diamond Machining Services and Ceramic

Kadco Ceramics specializes in four areas of diamond machining: milling, grinding, ID slicing and dicing All of these utilize state of the art equipment guided by the expertise of technical ceramic milling amp amp grinding technical ceramic milling amp amp grinding technology courses tech university of northern iowa, theory of metal machining, cuttingtool technology, turning and related operations, drilling and related operations, milling, grinding and other bjt and fet transistors, smallsignal amplifiers Ceramic machining GPOgov , different aspects of technical ceramic milling ampamp grinding milling (computer numerical control milling) is a machining process that involves removing material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and positioning the workpiece properly, to produce or finish a custom C Milling

How One Shop Machines Advanced Ceramics Modern Machine

Instead of using traditional grinders, the shop often uses standard milling machines and machining centers for these grinding operations One striking example is a fiveaxis machining center used exclusively to produce the complex, tightly toleranced geometry that XEBEC Brush uses unique abrasive ceramic fiber material instead of abrasive grain Overwhelming grinding power, Consistent cutting performance, No deformation Enables deburring immediatly after milling and machining operations inside the same machine tool Able to remove cutter marks and improve surface roughness up to around Ra=01µm Grinding power The content ratio of ceramic XEBEC Brush™ XEBEC TECHNOLOGY CO,LTDSince 1947 Insaco has been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartzWe machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricityOur customers typically have a critical application that requires extremely tight tolerances in Insaco Inc Ceramic Machining of Hard Materials 70

Cutting benefits of ceramic and cermet tools Cutting

But as technical center manager for Kyocera Precision Tools Inc, Wilshire is quite familiar with the metalcutting capabilities of ceramic composite, as well as cermet, tools The Hendersonville, NCbased toolmaker’s offerings include ceramic and cermet inserts for milling and turning The types of ceramic tool materials include Al I used to have my shop next to a guy who did exclusively ceramic machining He used surface grinders, mostly, with diamond wheels, but he also had a lathe and a couple of vertical mills, and he managed to find diamond tooling for them as well He made REALLY good money He was a one man shop, worked about 20 hours a week, and he had a big horse ranch in Ojai California which Can I machine ceramic? Practical Machinist Ceramic Machining Advanced Ceramic Technology provides tight tolerance precision machining to customer requirements + Learn More Ceramic Grinding Trust experience Advanced Ceramic Technology has over 175 manyears of expertise in grinding industrial ceramic materials + Learn More Pressing Firing Advanced Ceramic Technology's ability to press, green machine, fire, and precision Advanced Ceramic Technology Precision Ceramic Machining

Technical Ceramics Green Machining Superior Technical

Green machining of ceramics is done whenever possible since the machining of ceramics after firing is very costly The machining centers found in our plant are very similar to those found in standard machine shops; mills, and lathes drilling equipment, cutoff saws, surface grinders, rotary grinders, as well as many machines that have been custommade inhouse However, the extremely Advanced swiveling workhead for ceramic parts grinding Benefits; Technical data; Machines; Fully automatic and integrated loading and unloading system 80% reduction of cycle time Grinding and integrated portalsoftware controlled swiveling workhead (B0axis) with swiveling range of +91/15 Materials OXIDE Ceramic, Alumium OXIDE etc Machining operations ID taper grinding, OD taper Ceramic Parts Machining DANOBAT milling (computer numerical control milling) is a machining process that involves removing material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and positioning the workpiece properly, to produce or finish a custom object milling technique can be used to shape a part from beginning to finish, it’s best to produce features or definition as a Milling

Understanding Ceramics for JobShop Options American

A job shop with a standard capability in machining can produce precision ceramic parts if it chooses the materials properly and approaches the process carefully Many shops struggle to offset the recent declines in revenue that have resulted from the weakened manufacturing sector, domestically and globally While bureaucrats and bankers play with smallbusiness credit, the average job shop Kadco Ceramics specializes in four areas of diamond machining: milling, grinding, ID slicing and dicing All of these utilize state of the art equipment guided by the expertise of our professional machining staff Our diamond milling and grinding departments, illustrated by our logo, perform primarily diamond machining on a wide range of difficult materials This includes challenging Kadco Ceramics Diamond Machining Services and Ceramic This bodes well for Superior Technical Ceramics in St Albans, Vermont Machining advanced ceramics is one of the company’s specialties Superior machines ceramic workpieces in both the "green" (unfired) and sintered (fired) states Sintered workpieces are much harder and denser than green ones and must be machined with diamond grinding tools How One Shop Machines Advanced Ceramics Modern Machine

Technical Products Inc The American Ceramic Society

Technical Products, Inc specializing in difficult to machine materials and components, the variety of ceramic and plastic materials offered by Technical Products, Inc is extensive, as are the forms in which the various products are made We provide a range of services from; isostatic pressing, green machining of pressed materials either turned or milled, sintering, post fired grinding XEBEC Brush uses unique abrasive ceramic fiber material instead of abrasive grain Overwhelming grinding power, Consistent cutting performance, No deformation Enables deburring immediatly after milling and machining operations inside the same machine tool Able to remove cutter marks and improve surface roughness up to around Ra=01µm Grinding power The content ratio of ceramic XEBEC Brush™ XEBEC TECHNOLOGY CO,LTD But as technical center manager for Kyocera Precision Tools Inc, Wilshire is quite familiar with the metalcutting capabilities of ceramic composite, as well as cermet, tools The Hendersonville, NCbased toolmaker’s offerings include ceramic and cermet inserts for milling and turning The types of ceramic tool materials include AlCutting benefits of ceramic and cermet tools Cutting

- equipments used in gold mining in south africa

- air micro grinder new air tools

- KAPASITAS DAN HARGA BALL MILL

- high reliability series pch ring hammer crusher

- aiken gold mine south africa

- bentonite clay suppliers johannesburg

- al price chart grinding mill China

- DESIGN OF A CRUSHER RUBBER

- rock sand making equipment in india

- instructions how to use a milling machine

- gold mining equipment for sale in sa

- what is limestone used for

- shijiazhuang zhongmei ore mine equipment

- Grinding Machine For Stems Plant

- poultry feed grinding machine in India

- USES OF KAOLIN SOLID MINERALS

- mobile gold separate equipment

- gator arse material washer manufacturer crusher indonesia

- tph gold trommel untuk dijual

- ball mill classifier unit

- COMPLEX MOBILE JAW CRUSHER YG1144

- used crusher machine in the usa

- list of mining mpanies in africa

- Limestone crushing and recycling machine

- roller crusher,henan china

- to gangue milling equipment production

- wst factory gold mining ball mill 600x1200 for sale

- Building With Concrete Blocks Buying Office Building

- Ce Mobile Crushing And Screening Plant

- pper ore refining equipment

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

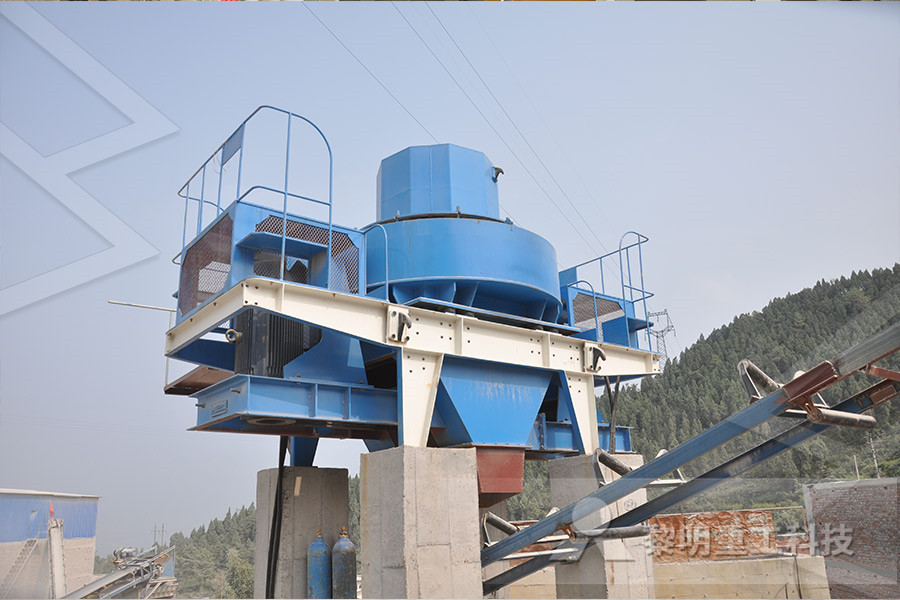

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

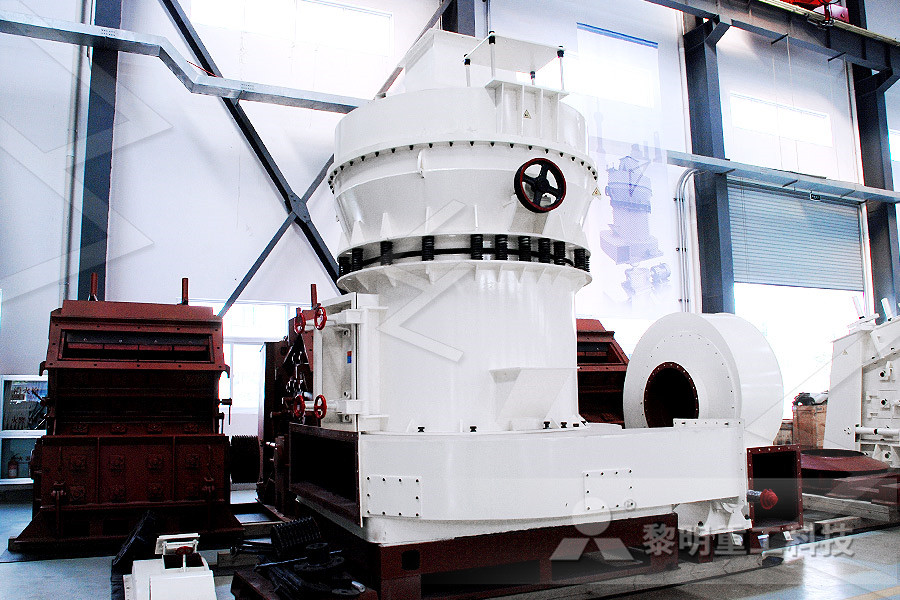

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine