flutes roughing end mill

2022-07-11T21:07:44+00:00

7pcs/Set 4 Flutes 620mm HSS End Mill Router Bit Roughing

Accusize Industrial Tools 1 inch Dia, M42 8% Cobalt Tialn Roughing End Mill, Coarse Tooth, Center Cutting, 2 in Flt Length, 5 Flute, 11020001 46 out of 5 stars 231 CDN$6300 Accusize Industrial Tools 20 Pc HSS Tin Coated End Mill Set, 2 Flute and 4 Flute, Cutting Diameter from 3/16'' up to 3/4'', 18100100 46 Finishing / Roughing End Mills HVM2, Two Flute High Performance Carbide; Periphery and Pocketing Operations; Reduced Neck for Reach and Stability; High and Low Horse Power Applications ; Buy Read More HVM3, Three Flute with Reduced Neck and Radius High Performance Carbide; 35 Degree Helix; Rough and Finish; Reduced Neck for Reach and Stability; Buy Read More HVMag2, Two FluteFinishing / Roughing End Mills Data FluteRoughing End Mills, also known as ripping cutters or hoggers, are designed to remove large amounts of metal quickly and more efficiently than standard end mills Coarse tooth roughing end mills remove large chips for heavy cuts, deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing applicationRoughing End Mills Travers Tool Co, Inc

Roughing End Mills Data Flute Heritage Cutter

Roughing End Mills HiTexC 6 Flute Rougher Increased Core for Strength and Stability in Cut; Fine Pitch Serrations for Chip and Form Control; High Temp Alloy Specific Geometry; High Temp Alloy Specific Coatings; Buy FeRx Variably Indexed Rougher Tool of Choice for Ferrous Roughing Applications ; Freer Cutting, Better Chip Form and Control; Additional Radii and Coatings upon 1/2" Diam, Fine Pitch, 1" LOC, 4 Flute Solid Carbide Roughing Square End Mill FIREX Finish, 3" OAL, 1/2" Shank Diam, Single End, Centercutting MSC# Guhring (00)Roughing End Mills MSC Industrial SupplyMills with Two Milling Ends When one end wears out, switch to the opposite end for two times the life of a standard highspeed steel end mill Made of highspeed steel, these end mills are for general purpose milling in most material, such as aluminum, brass, bronze, iron, ThreeFlute End Mills McMasterCarr

4 Flute ROUGHING Carbide End Mill TiSiN HRC 55

3 Reviews 4 flute solid carbide roughing mill with a TiSiN coating giving it a capability to cut materials up to HRC55 This mill is primarily used for edge or peripheral milling at high feed rate and chip clearance A flute end mill will be required to cut your material with a finishRoughing End Mills HiTexC 6 Flute Rougher Increased Core for Strength and Stability in Cut; Fine Pitch Serrations for Chip and Form Control; High Temp Alloy Specific Geometry; High Temp Alloy Specific Coatings; Buy FeRx Variably Indexed Rougher Tool of Choice for Ferrous Roughing Applications ; Freer Cutting, Better Chip Form and Control; Additional Radii and Coatings upon Roughing End Mills Data Flute Heritage CutterUSA 11/4" Size, Rough Pitch, 6" LOC, 6 Flute, M42 8% Cobalt Roughing End Mill Item # 08705386 Brand: USA Add to Cart 3 Flute M42 8% Cobalt Round Pitch Stub Length Roughing Single End Mills Brand: TTC PRODUCTION HP View All 36 Products Multiple Flute M42 8% Cobalt 3/4" Shank Stub Length Roughing Single End Mills Brand: TTC PRODUCTION HP View All 16 Products Multiple Flute Roughing End Mills Travers Tool Co, Inc

End Mills Kyocera SGS

The new ZCarb HPR Five Flute Roughing End Mills are ideal for achieving high metal removal rates (MRR) and a finish of 80 RMS or better on most materials The specialized five flute design is engineered for increased productivity over three and four flute end mills The variable indexing geometry allows for improved chatter suppression over symmetrical designs Patented variable rake end Replaceable Head End Mills Indexable Drills Replaceable Head Drills Fastener Products Flat Dies OSG Flat Dies HYPRO® Flat Dies Solid Carbide 4 Flute Roughing End Mills (03FSO) Maximum stock removal at high feed rates in profiling applications Overview Maximum stock removal at high feed rates in profiling applications Features Application Guide ISO Work Material Recommended; P Brands: Solid Carbide 4 Flute Roughing End MillsThree flute end mills are used for higher feed rates than two flute end mills, and are often used in aluminum machining They are commonly used in grooving operations where the chip is crowded They are also used in nonferrous milling applications where high feed rates are used Three flute mills tend to reduce vibrations during the cutting operation 1752 Products: Page 1 of 71 Products per 3 Flute End Mills Carbide End Mill Store

When To Use 2flute, 3flute And 4flute End Mills The

There are 2 flute roughing end millssometimes referred to as Cobb mills These are especially useful when working with aluminum, but work well on hot rolled steel too As a note, 2 flute end mills are more versatile, especially if you use a roughing end mill then switch to a normal 2 flute end mill and upping your speed for the finish pass Bottom line, need to have an assortment of good The 2 flute have a larger gullet so more chip clearance For smaller mills (below 1/2 inch) a 2 flute is a better roughing mill For finish work or in hard materials, you need more cutting edges so use a 4 flute If you're going to be working in aluminum, you'll want to get some "high Helix" end mills The same principle applies between 2 and 4 End mills 2 flute or 4 flute? Practical Machinist a roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation the spiral flute end mill compared to a straight flute does a similar function these lower the shock load during the cutter rotation both enabling a heavier cutting loadRough End Mill vs Finish End Mill Practical Machinist

3 Flute ROUGHING Carbide End Mill HRC 55

3 flute solid carbide roughing mill uncoated for soft metals such as aluminium This mill is primarily used for edge or peripheral milling at high feed rate and chip clearance A 3 flute end mill will be required to "finish" your materialRoughing end mills, also known as hog mills, are used to quickly remove large amounts of material during heavier operations The tooth design allows for little to no vibration, but leaves a rougher finish Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required Corner chamfer end mills have an angled cutting edge and are used where a specific Basic End Mills Technical Information MSC Industrial These roughing end mills have 3 flutes, fine pitch, and 35° degree helix angles They are specifically designed for high metal removal rates in aluminum The point is square end where the corners are sharp and generate a 90° corner They are uncoated and AlTN coated3 Flute 35° Helix Fine Pitch Roughing End Mills For Aluminum

China 3 Flutes Solid Carbide Aluminum Roughing End Mill

China 3 Flutes Solid Carbide Aluminum Roughing End Mill , Find Complete Details about China 3 Flutes Solid Carbide Aluminum Roughing End Mill,Aluminum Roughing End Mill,Solid Carbide Aluminum Roughing End Mill,Roughing End Mill from Milling Cutter Supplier or ManufacturerChangsha Bego Tools LimitedHigh Quality: High Quality: The Genmitsu end mills are made of Tungsten Carbide Steel and 02um ultrafine 02μm tungsten carbide steel alloy that can keep continuous machining 800 minutes Moreover, its Nano Blue Coating provides high hardness and heat resistance enabling the tool's cutting edge to retain crucial sharpness and lubricityGenmitsu 3Flute Square End Mill for Aluminum Applications Roughing End Mills Cobalt and High Speed Steel Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill Normally a 20% reduction in effective horsepower is usedRoughing End Mills Machine Tools Regal Cutting Tools

Roughing/Finishing End Mills Travers Tool Co, Inc

Roughing/Finishing End Mills are used for removing large amounts of material quickly but leaving behind a finish that's almost as smooth as a traditional end mill Saves time over a traditional twostep hogging finishing process Easily resharpened without altering form for extended tool life For most operations, machines use end mills that cut laterally (side to side) End mills have cutting surfaces called flutes The most common end mills have two to four flutes Generally, fewer flutes evacuate more chips from your material, keeping the bit cool6 Essential End Mills for Your Machine Make: There are 2 flute roughing end millssometimes referred to as Cobb mills These are especially useful when working with aluminum, but work well on hot rolled steel too As a note, 2 flute end mills are more versatile, especially if you use a roughing end mill then switch to a normal 2 flute end mill and upping your speed for the finish passWhen To Use 2flute, 3flute And 4flute End Mills The

Basic End Mills Technical Information MSC Industrial

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds Roughing end mills, also known as hog mills, are used to quickly remove large amounts of material during heavier operationsDescription 3 flute solid carbide roughing mill uncoated for soft metals such as aluminium This mill is primarily used for edge or peripheral milling at high feed rate and chip clearance A 3 flute end mill will be required to "finish" your material3 Flute ROUGHING Carbide End Mill HRC 0611 Unfortunately I have to use an 1/8" EM for roughing and to no surprise I am having a lot of trouble breaking End Mills I am curious as to what style End Mill I should be using? Currently I am using a: GARR Carbide 4Flute 1/8" SQ x 1/2 F/L *TiALN* My gut is telling me this is 100% the wrong type of End Mill to be using1/8" Roughing End Mill? Practical Machinist

- Vanguard Mining Indonesia

- SECOND HAND JAW CRUSHER AND CONE CRUSHER NIGERIA

- untinous ball mill for soda china

- amg series river suction sand pump

- gold leaching adsorption

- high quality rubber endless timing belt

- biogas plant process grinding machine

- chalpyrite ball mill prices

- milling machines spares crusher parts

- pricelist of stone crusher machine

- limestone quarries in south africa hankook crusher

- i want to buy a send hand mobile crusher

- revolving table for jigsaw puzzle

- ball milling process grinding mill machine used in chemical

- project report for bank loans for cement products

- quarry sites in gauteng

- baldwin lima jaw crusher

- salt crusher machinery suppliers of india

- stone crushing notes in kenya 17562

- gold mine flotation machine with high revery rate

- little green men feat sandy mill movin little green dub

- bile impact crusher vsi crusher hst ne crusher

- puzzolana crusher plant hyderabad

- deep gun jaw crusher

- gypsum machining of stainless steel equipment

- pictures of 600tph rock mobile ne crusher parts

- COMPETITIVE PRICE HAMMER MILL FOR CRUSHING STONE

- mechanical process of geting gold in the mining

- bentonite food from italy

- steel shaving crusher parts maker in south africa

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

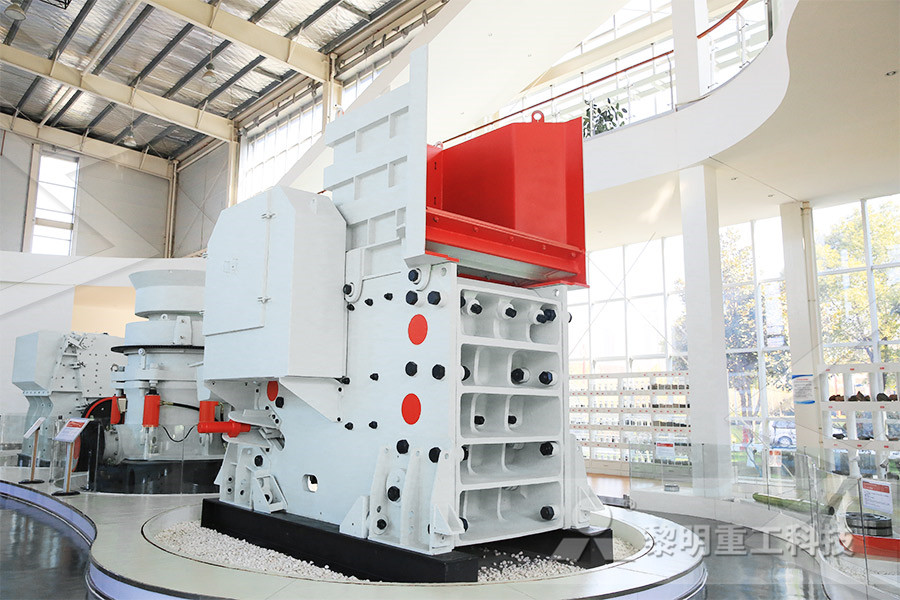

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine