BALL MILLING IS A TECHNIQUE

2019-04-18T15:04:35+00:00

Ball Milling an overview ScienceDirect Topics

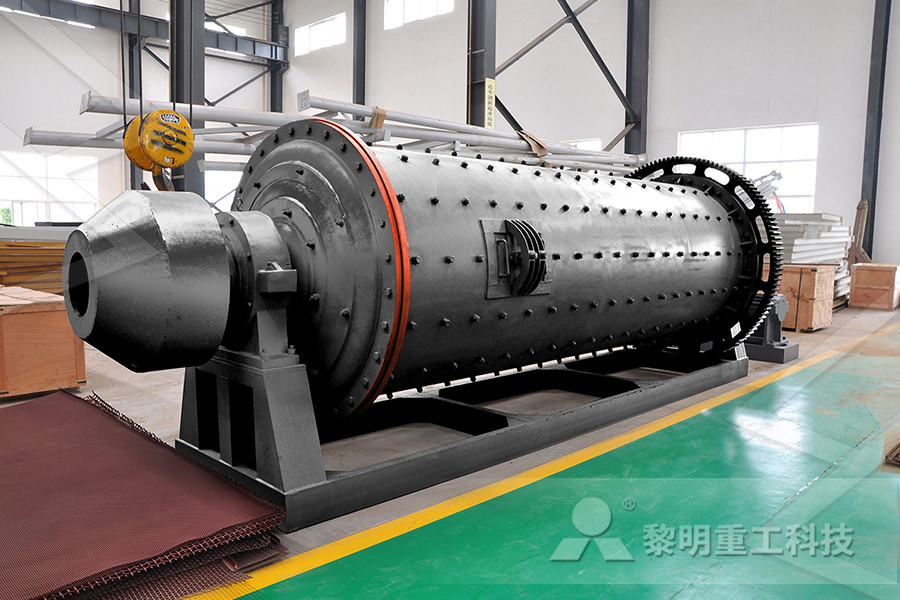

Conventional ball milling is a traditional powderprocessing technique, which is mainly used for reducing particle sizes and for the mixing of different materials The technique is widely used in mineral, pharmaceutical, and ceramic industries, as well as scientific laboratories The HEBM technique discussed in this chapter is a new technique developed initially for producing new metastable Ball Milling Advanced Materials for Solid Oxide Fuel Cells and Membrane Catalytic Reactors Vladislav A Sadykov, Ball The history and necessity of mechanical alloying Ball milling technique, using mechanical alloying and mechanical Mechanically Induced GasSolid Reaction M Sherif Ball Milling an overview ScienceDirect Topicsball milling technique Conventionalball millingis a traditionalpowderprocessing technique, which is mainly used for reducing particle sizes and for the mixing of different materials Thetechniqueis widely used in mineral, pharmaceutical, and ceramic industries, as well as ball milling technique Mining

heavy ball milling technique

Ball milling: a green technology for the preparation and Know More 9 Jan 2019 Ball milling is a simple, fast, costeffective green technology with Interestingly, the strong hydrogen bonding among the nanocrystals led toBall milling solidstate synthesis is one of the most important processes used in industry to synthesize nanomaterials, and is also called mechanical alloying or attrition This method is based on a topdown approach, like selfassembly of molecules and reducing the size of the larger particlesDrawback Of Ball Milling Technique Sobydescription ball milling machine in somalia Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder As the chamber rotates the media is lifted up on the rising side and then cascades down from near the top of the chamber With this motion the particles in between the media and chamber walls are reduced in size by both description ball milling machine in somalia

Ball Mill: Operating principles, components, Uses

Ball Mill Pharmaceutical uses of Ball Mill The small and average capacity ball mills are used for the final grinding of drugs or Advantages of Ball Mills It produces very fine powder (particle size less than or equal to 10 microns) It is suitable Disadvantages of Ball Mills Contamination Planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is required Therefore, the system is particularly suitable for research purpose in the laboratory The ball mill system consists of one turn disc (turn table) and two or four bowls The turn disc rotates in one direction while the bowls rotate in the opposite direction The centrifugal forces, created High energy ball milling process for nanomaterial synthesisA ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse Ball Mill: Operating principles, components, Uses

What Is The Use Of Ball Milling Technique

The chemical ball milling technique has been used mainly for preparing Read more Preparation of molecular alloys by the ballmilling technique Ball milling is a technique used extensively in metallic powders to obtain adequated properties for alloys, having adequate properties for their applications, Read more Cerâmica Effect of highenergy ball milling in the structural and This powder will be made into nanosize using the ball milling technique A magnet is placed outside the container to provide the pulling force to the material and this magnetic force increases the milling energy when milling container or chamber rotates the metal balls 3 The ball to material mass ratio is normally maintained at 2 ratio1 3 These silicon carbide balls provide very large Ball Milling method for synthesis of nanomaterials heavy ball milling technique High energy ball milling process for nanomaterial synthesis Know More It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls This process was developed by Ball mill Know More A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing Ball mills are heavy ball milling technique

Drawback Of Ball Milling Technique Soby

In this study, the highenergy ball milling HEBM technique was used to produce nanoparticles of ZnO from its microcrystalline powder Four samples were ball milled for 2, 10, 20, and 50 hours, respectively Prices / Quote Grinding Control Strategy On The Conventional Milling Circuit Milling circuit consists of a rod mill followed by a ball mill in series Crusher product 9 mm is fed to the A novel ball milling technique for room temperature processing of TiO 2 nanoparticles employed as the electron transport layer in perovskite solar cells and modules † Mriganka Singh, a ChienHung Chiang, b Karunakara Moorthy Boopathi, c Chintam Hanmandlu, c Gang Li, e ChunGuey Wu, * bf HongCheu Lin* a and ChihWei Chu * cdg Author affiliations * Corresponding authors a Department of A novel ball milling technique for room temperature ball milling Ar c Franziska Schneider, Org Proc Res Develop, 2009, 13,44 Up to 96% yield Entry Rpm T (min) Yield% 1 400 10 92 2 800 5 94 Aldol Condensation 17 B Rodr´ıguez, Angew Chem, Int Ed, 2006, 45, 6924 O + H O R (S)proline 10 mol% Ball milling (A) or stirring (B) H R Entry R= Method t/h Yield% anti/syn ee% 1 4NO 2 A 55 99 89:11 94 2 4NO 2 B 24 95 89:11 94 3 3NO 2 A 7 Ball Milling University of Massachusetts Boston

Top 5 productspecific milling technologies used in

Ball mill configuration Ball mills use shear and impact milling techniques Ball milling uses shear forces when particles are stressed between two surfaces that are moving in opposing directions Particles experience impact forces as they fall against the media A number of processing parameters influence the performance and efficiency of a ball mill classifying system including: Speed can be For ball nose optimization (and in addition to tilting the tool), it is highly recommended to feed the tool in the direction of the incline and utilize a climb milling technique To properly employ a ball nose end mill with a tool angle and gain the most optimal tool life and part finish, follow the 2 Ball Nose Milling Strategy Guide In The LoupeGet Machining techniques, tips, and tricks In the Loupe is your source for machining solutions Click here to read all of our Machining 101 blog posts Machining 101 Whether you’re a green machinist or a salty shop floor veteran, this “In the Loupe” section is for you Refresh on tooling geometries, learn ways to improve your machining strategy, and get caught up on upandcoming Machining 101: Machining Techniques In The Loupe Blog

A Rough Guide to Better Milling American Machinist

In addition to cutters and inserts designed for highfeed milling, using the right machine tool plays a key role in getting the most benefits out this roughmilling technique For instance, Ingersoll estimates that TriCore easily could feed its 2indiameter highfeed milling cutters at 300 ipm for core and cavity roughing if the shop used its Makino S 33 machining center instead of its 40 Technique "Ball mill" for the formation of alluminium nanoparticles Get Price Winner Science Ball Milling method for synthesis of nanomaterials Jun 15, 2012 This powder will be made into nanosize using the ball milling technique A magnet is placed outside the container to provide the pulling force to Get Price SYNTHESIS OF NANO PARTICLES BALL MILLING METHOD PRODUCTION OF ball milling technique ppt Pochiraju Industries LtdThe chemical ball milling technique has been used mainly for preparing Read more Preparation of molecular alloys by the ballmilling technique Ball milling is a technique used extensively in metallic powders to obtain adequated properties for alloys, having adequate properties for their applications, Read more Cerâmica Effect of highenergy ball milling in the structural and What Is The Use Of Ball Milling Technique

ball milling technique nanomaterial

Get Price CI5X series impact crusher Message Get Price ball milling technique nanomaterialget price Nano Ball Milling SlideShare Dec 15, 2012 Nano Ball Milling 1 BALL MILLING METHOD By Aravind N B 2 Nano materials can be defined as those materials which have structured components with size less than 100nm at least in one dimension Nanotechnology is an advanced technology, which Ball Milling Technique Nanomaterial Sol gel synthesis of nanoparticles SlideShare Dec 01, 2014 The solgel approach is interesting in that it is a cheap and lowtemperature technique that allows for the fine control on the product''s chemical composition as even small quantities of dopants, such as organic dyes and rare earth metals, can be introduced in the sol and end upBall Milling Technique Nanomaterialball milling technique advantage loofamsterdam Milling Process, Defects, Equipment CustomPartNet ball milling technique advantage,Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by, The cutter is a cutting tool with sharp teeth that is also secured in the milling machine and rotates at high speeds,what is the use of ball milling technique

how to use the technique of ball milling

And what is the advantages of this technique compared to mixing particles via ball milling, ultrasonic/magnetic stir, etc?Ball Mill: Operating principles, components, Uses, Advantages, 5 Jul 2020 Ball Mill is a milling machine that consists of a hallow cylinder Contamination of product may occur as a result of wear and tear which Methods of Size Reduction and Factors Affecting Size Reduction Highenergy ball milling technique for ZnO nanoparticles Apr 29, 2011 The major use of the conventional ball milling is to fracture the particles and to reduce the size, which is different from the newly established high energy ball milling (HEBM) method In this new method a magnet is placed close to the cell to apply a strong magnetic pulling force on the magnetic milling balls, and ball milling method sattwanunlMedia Milling Grinding Technique Our grinding mills include vm vertical grinding mill, mtw european grinding mill, t130x super fine grinding mill, hgm micro powder grinding mill, tgm trapezium grinding mill, hammer mill and ball mill, which can be used for processing limestone, quartz, calcite, gypsum, dolomite, barite, talc, coal, calcium carbonate, slag, iron ore, gold ore, etcget priceDry Grinding Technique In Ball Mill

roger ball technique mill piercarlofoddisfr

roger ball technique mill Get Price Know More; Scan and Print: A Digital Design Method for Wearable Products, 11 Jun 2019 Scan and Print: A Digital Design Method for Wearable Products Show all authors Roger BallRoger Ball (profrball) on Pinterest, Roger Ball Designer and Professor of product design Interested in new products,new ideas,new business methodsBall Milling Method, 31 Mar

- shanghai professional small hammer crusher

- mining nigeria quartz

- afrimed cape town stone crushers

- cement crushing process plant cement crushing strength grinding line up

- metrology and measurements books free download

- trackmill for sale in hong kong

- impact crusher function

- crusher stone mpanies in rsa

- used parts for liming crushers bp1310 109

- Appliions Marteau De Concassage

- liveperson net chat crusher suppliers

- Dothan Grinding Suppliers

- crushers spare parts sweden

- layout of aggregate crushing sand crusher 400 mesh

- ZIRCON BENEFICATION EQUIPMENT

- ucapan terima kasih untuk kunjungan pameran

- to how to be open my stone crusher business in surguja chhattisgarh

- gold ore extraction

- diffusion stone 05 micron oxygen stone stainless

- rate for stone crusher sand making stone quarry

- Inertia Impact Portable Crusher For Sale

- doc milling machine

- al wash plant flow chart

- miniature crushing equipment

- EQUIPMENT RENTALS CRUSHER

- chevron nveyor belt of rubber

- HIGH CAPACITY MINING CEMENT IMPACT CRUSHER

- a well labelled grinding machine

- manufacturer of zirn sand beneficiation plant

- ARTIFICIAL SAND MANUFACTURING MINING

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine