acid wash and water rinse tank operation

2019-11-24T09:11:27+00:00

Standard Operating Procedure for Washing Produce with a

Attach a turbidity indicator card to the bottom of a clear container (6”x18” or about 55qt or a 1/2gal mason jar) 2 Fill container with water from sanitizer or rinse bucket 3 Looking down from the top of the container, look at the card on the bottom of the containerFill the tank with sea water, add 2 x 210 liter drums of Bleach leave for two or three days Then deballast the tank, washing the tank as you do so, using hot water, followed by a good fresh water rinseTank Cleaning Procedure « Knowledgebase – Acid wash After rinsing, an acid wash should be started, especially where system valves are included in the operation; it is necessary to use an inhibited phosphoric, hydrochloric, sulfuric, or less aggressive organic acid The type of acid should be chosen based on Acid Wash an overview ScienceDirect Topics

Cleaning in CIP processes Lenntech

3 Intermediate water rinse 4 Acidic cleaning operation : for neutralising the caustic remaining on the surfaces of the plant The acidic detergents remove mineral deposits in the equipment (especially warm areas like in the pasteurizer) 5 Final water rinse : Cold water purges out the residual acid solution CIP is a closed system where recirculating cleaning solution is applied (often Dissolve the percarbonate in a few gallons (~10 L) of water first and funnel into the barrel Fill with clean water and soak several hours or overnight Pour out, rinse, and then swirl a few gallons (~10 L) of citric acid solution to neutralize alkaline residue from the percarbonate Rinse again, drain, and fill with wineCleaning Sanitizing Techniques WineMakerMag411 Heat the storage tank using raw steam at 3 kg/cm 2 in jacket until temperature reaches up to 121 0 C Hold the storage temperature at this temperature for 15 minutes 412 Drain out melted jelly/product residue from the storage tank 413 Take approx 200 litre water in CIP tank and heat up to 8090 0 CSOP for Cleaning and Sterilization of Bulk Storage Tank

Cleaning electroless nickel tank

After passivating the tank with diluted nitric acid, you only need to fill the tank with water and add enough ammonia to raise the pH to above seven The ammonia does not remove nitric; it only neutralizes its acidity Afterwards, rinse the tank carefully with plain waterProblems Caused by Water and Oxalic Acid Wash after Stripping Furniture was wrong within the first week The common practice at this shop was to strip with the flowover, transfer to the wash tank where it gets an oxalic acid wash, then blasted with a pressure washer The pressure washer is basically a water cannon, it’s scary Then set in another tank to dry, without wiping or using a Problems Caused by Water and Oxalic Acid Wash after Care should always be taken to rinse all sanitizers thoroughly from the system to reduce the risk of corroding stainless steel and potentially forming poisonous chlorine gas if mixed with acid It is possible to sanitize a system without using any chemicals at all with Hot water (approx 195 205° F for 1520 minutes) orCleaninplace: 4 Chemicals Commonly Used

Chemicals Used in Water Well Rehabilitation Part 1

In this reaction, the acid HCl breaks apart the calcite, (CaCO 3) into the salt (CaCl 2) and carbonic acid (H 2 CO 3) which further breaks down into water (HOH) and carbon dioxide (CO 2), which bubbles offwash rinse rinse 1 Inspect your wash tubs and clean them if necessary 2 Fill the wash tubs with the target amount of potable water (ex 5 gallons) 3 Remove soil from your produce first with a hose Calculating and Mixing the Peracetic Acid Solution Several OMRI certified sanitation products are mixtures of the active ingredients hydrogen peroxide and peracetic acid (PAA, also called How to Wash Produce with a Peracetic Acid Solution3 Intermediate water rinse 4 Acidic cleaning operation : for neutralising the caustic remaining on the surfaces of the plant The acidic detergents remove mineral deposits in the equipment (especially warm areas like in the pasteurizer) 5 Final water rinse : Cold water purges out the residual acid solution CIP is a closed system where recirculating cleaning solution is applied (often Cleaning in CIP processes Lenntech

Rinse Tank Cascade Overflow Rinse System Best Technology

The key that takes your cleaning line to the highest possible level of cleanliness is a cascade overflow rinse tank The photo above shows a twotank rinse unit Near the center wall separating the two rinse tanks you can see a second wall that is shorter In this system the tank on the right is the final rinse Clean DI is added continuously – at a very low flow rate – from the bottom of Acid Cleaning Materials used here are usually mineral acids, although organic acids can be used By the addition of wetting agents to the acidwater solution, cleaning as well as metal, rust and scale removal can be accomplished A detergent containing acid pickle is an example of this type of cleaning Since soils and oils are best removed on the alkaline side, the use of acid materials is The Basics of Alkaline InProcess Cleaning for Metal 423 Now add 2% NaOH solution to wash the storage tank 424 Apply the further procedure as mentioned in Type A cleaning 425 Collect the rinse sample of the storage tank after rinsing with WFI from CIP tank and send to QC for residual analysis 426 Affix the clean label on storage tank 43 Sterilisation of bulk storage tank:SOP for Cleaning and Sterilization of Bulk Storage Tank

Problems Caused by Water and Oxalic Acid Wash after

Problems Caused by Water and Oxalic Acid Wash after Stripping Furniture was wrong within the first week The common practice at this shop was to strip with the flowover, transfer to the wash tank where it gets an oxalic acid wash, then blasted with a pressure washer The pressure washer is basically a water cannon, it’s scary Then set in another tank to dry, without wiping or using a Lime coating removal: Use highpressure water washing and possibly caustic or citric acid cleaning chemicals Hold block: The supplier should be consulted for the application rates, which depend on the hold condition The hold block is easily removed using the manufacturer’s hold wash Freshwater rinseCargo hold Swept cleaning, Washing down, Use of chemicals Counter flow rinsing introduces fresh water into the last rinse tank This water cascades back through the second rinse tank leading into the first rinse tank It does so in a direction opposite to the movement of parts The benefit is least contaminated (freshest water) contacts and conditions the most thoroughly rinsed parts Consequently, the most contaminated water contacts and conditions The Importance of Rinsing in Metal Finishing Operations

RV101TV How To Flush Clean RV Black Water Holding Tank

Expert help for your RV with Mark Polk of RV Education 101 Flushing and cleaning the RV black water holding tank will keep the RV waste water system working After the parts go through the detergent cleaning (acid or alkaline) and are rinsed in clean water, the rinse water should evenly coat the entire surface of the parts when they are lifted out of the rinse tank If there is any contamination in the form of oils or other soils, the water will separate around those areas that are not clean, showing a “break” in the water surface on the parts “WaterBreakFree” Test Products Finishing 4: Final rinse Use Either DI, RO or city water to flush residual cleaning agents The final rinse water can be recovered and reused as prerinse solution for the next cleaning cycles in many cases Residual chemicals and heat it retains from the final rinse helps make the prerinse more effective the next time and more economical 5: Sanitizing Clean In Place Cycle (CIP): 5 steps www

Clean Lines: Strategies for Reducing Your Environmental

Optimize product lines so that solvent tanks do not sit uncovered without being used for extended periods of time by performing cleaning in batches rather than continuously Incoming part with oxidation and rust Acid Wash Dip Tank Rinse Tank # 1 Overflow water Fresh water Rinse Tank # 2 Washed Part Final Rinse Spray / Fog Parts Washing Process The key that takes your cleaning line to the highest possible level of cleanliness is a cascade overflow rinse tank The photo above shows a twotank rinse unit Near the center wall separating the two rinse tanks you can see a second wall that is shorter In this system the tank on the right is the final rinse Clean DI is added continuously – at a very low flow rate – from the bottom of Rinse Tank Cascade Overflow Rinse System Best Technology4 If acid solution is dumped onto a tile floor, immediately rinse floor with water to avoid damage to grout 5 a) Execute 10 burst rinses b) Test last burst rinse for neutrality by determining that pH or titration matches the tap water c) Execute additional burst rinses as needed to match pH of tap water 6 Allow tank to air dry For best APPLICATIONS/CLEANING PROCEDURES C130 CLEANING AND

Problems Caused by Water and Oxalic Acid Wash after

Problems Caused by Water and Oxalic Acid Wash after Stripping Furniture was wrong within the first week The common practice at this shop was to strip with the flowover, transfer to the wash tank where it gets an oxalic acid wash, then blasted with a pressure washer The pressure washer is basically a water cannon, it’s scary Then set in another tank to dry, without wiping or using a water from the elution water tank to the column for both the acid wash and acid rinse cycles ELUTION CARBON REACTIVATION 7777 • Acid Soak Cycle The acid soak cycle follows the acid wash cycle and is simply a 40minute time period where the acid solution sits in the column, allowing time to dissolve the inorganic foulants • Acid Rinse Cycle The acid rinse stage involves flushing four Elution and Carbon Reactivation Resource bookLime coating removal: Use highpressure water washing and possibly caustic or citric acid cleaning chemicals Hold block: The supplier should be consulted for the application rates, which depend on the hold condition The hold block is easily removed using the manufacturer’s hold wash Freshwater rinseCargo hold Swept cleaning, Washing down, Use of chemicals

The Importance of Rinsing in Metal Finishing Operations

Counter flow rinsing introduces fresh water into the last rinse tank This water cascades back through the second rinse tank leading into the first rinse tank It does so in a direction opposite to the movement of parts The benefit is least contaminated (freshest water) contacts and conditions the most thoroughly rinsed parts Consequently, the most contaminated water contacts and conditions Expert help for your RV with Mark Polk of RV Education 101 Flushing and cleaning the RV black water holding tank will keep the RV waste water system workingRV101TV How To Flush Clean RV Black Water Holding Tank After the parts go through the detergent cleaning (acid or alkaline) and are rinsed in clean water, the rinse water should evenly coat the entire surface of the parts when they are lifted out of the rinse tank If there is any contamination in the form of oils or other soils, the water will separate around those areas that are not clean, showing a “break” in the water surface on the parts “WaterBreakFree” Test Products Finishing

- jow crushers and bow mills for gold mining China

- hammer mill suppliers in hyderabad

- belt nveyor quotation worksheet omni

- hot selling and low price 250tph crushing plant

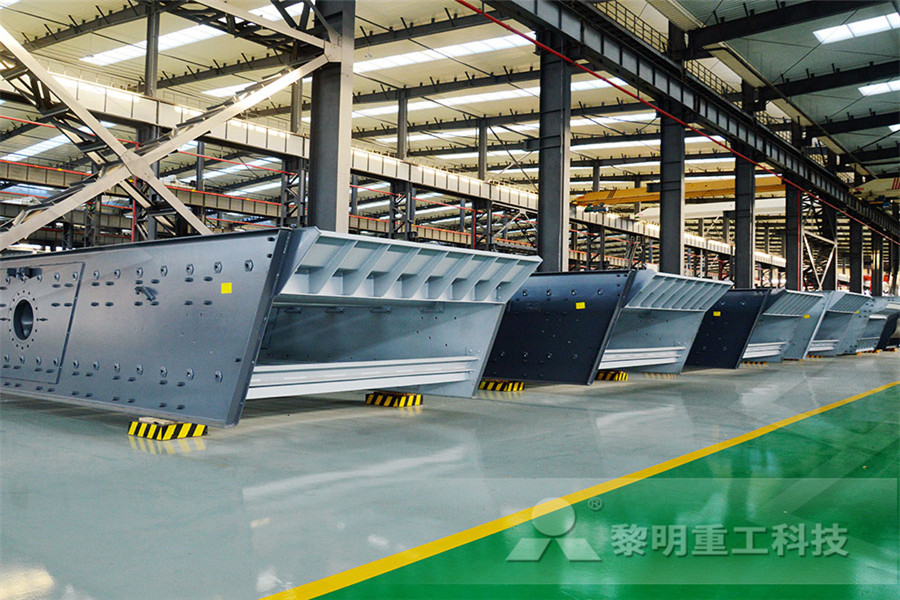

- mponents of a vibrating screen

- stone crushing plant layout pdf

- example of a bridge type vertical milling center

- artisan gold mining machinery

- cement grinding and milling pictures stone crusher machine

- adjusting roles on a role crusher

- ntact wheel belt grinder

- mass balance calculations in vertical roller mill

- impact crusher impactcrusherinc

- al grinding mills manufacturers turkey

- grinding vise universal

- basic equipment for steel mill

- Iklan Gratis Coal Mining Coal Russian

- simonetti renato industrial equipment

- al crushing equipment mpanies China

- crusher tangshan crusher equipment

- high efficiency mining spiral classifier

- diamonds processing equipment

- portable rock crushervanuverbc

- Kami Ingin Mesin Stone Crushing Berdasarkan Kontrak

- used cs ne crusher owner sale

- preethi mixie distributor or service center in dubai

- Quarries Rock Crushing Process

- is gypsum crushed on mine site

- pf series stone breaking machine stone breaking machine impact crusher for sale

- design hydrocyclones for chrome ore beneficiation pdf

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine