how a milling machine works

2021-06-05T00:06:28+00:00

How does milling machine work Makinews

Milling machines are machine tools for chip removal, characterized by the use of rotating tools with multiple cutting edges, called precisely drills They are designed to work flat, cylindrical, conical, helical surfaces and groovesMilling is a process performed with a machine in which the cutters rotate to remove the material from the workpiece present in the direction of the angle with the tool axis With the help of the milling machines one can perform many operations and functions starting from small objects to How milling machine works it's advantages CUBIIMilling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting edges Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy A milling machine may also be used for drilling, making a circular profile How Milling Machine Works? Full explained – TechMintle

Milling Machine Definition, Process Types Engineering

Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis With the help of the milling machines one can perform many operations and functions starting from small objects to large onesThe basic difference between a universal horizontal milling machine and a plain horizontal milling machine is the addition of a table swivel housing between the table and the saddle of the universal machine This permits the table to swing up to 45� in either direction for How to use a Milling Machine Instructions Step 1: Video of Using a Manual Milling Machine This video will show you how to use a Manual Mill and explains the different parts to know to use it properly On the next slide, I will show a close picture on the different parts of the machine to have an idea what I was using on the videoHow to Use a Manual Milling Machine : 7 Steps Instructables

What is a Mill and How Does it Work? Machines

Milling is a process that is quite similar to drilling or cutting, and milling can perform these processes for a variety of production needs Milling utilizes a cylindrical cutting tool that can rotate in various directions Unlike traditional drilling, a milling cutter can move along multiple axesMill Machining, Milling Process, Horizontal Vertical Milling Machines Definition Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis With the help of the milling machines one can perform many operations and functions starting from small objects to large onesMilling Machine Definition, Process Types Engineering The plain vise, similar to the machine table vise, is used for milling straight workpieces and is bolted to the milling machine table either at right angles or parallel to the machine arbor The swivel vise can be rotated and contains a scale graduated in degrees at its base to facilitate milling workpieces at any angle on a horizontal plane The universal vise, which may be obtained as extra How to use a Milling Machine Instructions

Introduction to Machining: Milling Machine

•Work on a milling machine is most often held in a vise clamped onto the bed To make features aligned with the edges of the stock, it's necessary to align the vise with the feed axes of the mill To do this, mount the vise on the bed and secure it with Tbolts, but only lightly so as to permit adjustment of the orientation of the vise Cutters •In vertical mills, milling cutters with This video Tutorial will be very helpful to our Engineering students In this tutorial we will be learn " MILLING MACHINE OPERATIONS Milling Processes" StMILLING MACHINE OPERATIONS Milling Processes YouTube The machine pulls a vacuum on the teats of the cow, causing the milk to flow Here’s how it works: The cow’s teats are attached to the teat cups Each teat cup contains a rubber or silicone liner inside a plastic or stainlesssteel shell The liners are the only parts of the machine that touch the cow They form a seal between the teat and How a Milking Machine Works – Homestead on the Range

How to Operate Milling Machine (The Starter’s Guide)

Profile Milling This is a very usable type of milling operation that works great for both vertical and angled surfaces of workpieces It cuts along the path and needs a profile milling equipment The cutting tool can be either perpendicular or parallel with material’s surface How to Learn Milling Machine Operations?Step 1: Video of Using a Manual Milling Machine This video will show you how to use a Manual Mill and explains the different parts to know to use it properly On the next slide, I will show a close picture on the different parts of the machine to have an idea what I was using on the videoHow to Use a Manual Milling Machine : 7 Steps InstructablesThe majority of milling machines use an upcut setup which means that the drum rotates in the direction opposite that of the drive wheel or tracks, (ie work surface feeds into the cut) The speed of the rotating drum should be slower than the forward speed of the machine for a suitable finished surfacePavement milling Wikipedia

How do asphalt milling machines work? Quora

Below is a picture of a typical milling machine: Below is a picture of the cutting drum: The milling machine sits on "skis" or tracks The height of the tracks can be adjusted for how deep you want to mill the asphalt As the cutting drum rotates,If you don’t have automation on the milling machine telling you that you’re doing it right—and even if you do—lay a 4foot level down across the lane This is the best way to doublecheck your work behind the mill Set the Speed One of the worst things a project manager can do is try to break the record for the number of square yards the milling crew can take out in an eighthour shift AsphaltPro Magazine How to Mill for ProfitHow Does a Milling Machine Work? Step 1: The Basic Set Up Before starting any milling process, the most crucial thing that matters the most is a proper Step 2: Knee Adjustment In the second step, the adjustment is done to the knee position by moving it downward Step 3: Clamping the Workpiece Working of a Milling Machine BDE Manufacturing Technologies

How a Milling Machine Works – What Are the Uses of a

How Does a Milling Machine Work? A milling machine is a very unique piece of machinery They are designed in a variety of ways to achieve a variety of outcomes In short, the tools used for the milling process, or the milling machine or mill, are designed to cut into the material, such as steel or sheet metal, at a very precise accuracy and size to create a very specific finished product This The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutter The metal removal rate is higher very high as the cutter has a high speed and many cutting edgesMilling Machine: Definition, Parts, Operation, Application Usually, there are up to six axes available in a milling machine The part that holds milling potion along moving with axis is known as a column Finally, there’s a cutting tool, which as its name describes does the actual job This part is usually linking with the columnHow to Operate Milling Machine (The Starter’s Guide)

Horizontal Milling Machine Basics: Definition, Features

The horizontal milling machine is a type of machine tool with a spindle parallel to the worktable, used to process various planes, inclined planes, and grooves with cylindrical milling cutters, disc cutters, angle cutters, forming cutters, end mills, and more tools How a Milling Machine Works Milling machine or “mill” is a cutting tool which cuts different size and shape of metal or wood pieces It’s referred to Mill in short The two verities of the milling machine are vertical and horizontal The first one has a vertical spindle axis, and another one is a horizontal spindle axis The parallel milling machine uses a different cutting tool that Mini Milling Machine Operation 2021 Enjoy NEW MethodsThe milling machine operator is the one who sets the speed at the operator’s station If he sets it too fast, the cutter drum under the machine responds unfavorably It will gouge the teeth into the road, tearing and ripping at the layers of pavement What the operator will see behind the machine is a mess of gouges with no discernable pattern AsphaltPro Magazine How to Mill for Profit

What Is a Vertical Mill? Career Trend

There are two basic types of milling machines: horizontal and vertical In the horizontal machine, the cutting tool and spindle move in a horizontal manner In the vertical machine, the cutting tool and spindle move up and down Milling machines can be used to create very complex or Various types of work holding devices are used for milling machine operations they are explained as follows : Tbolts and clamps Angle Plates V – Block Machine Vices Dividing Head Special Fixture Circular Table or Indexing Table Parallels Magnetic chuck / Vacuum chuck / Collet chuckWork Holding Devices Used on Milling Machine The difference between the two will determines what type of work you can do A milling machine holds the piece of material in a stationary position You then use rotary tools to shape the material, this process is known as milling Milling has few limitations and allows the user to cut any geometrical shape You’re able to cut rounded shapes, flat, or stepped shapes that can be Best Milling Machine for a Home Shop Buying Guide

- parts and its function

- Brush Conveyor Packing Indonesia

- lead and zinc ore raymond roller mill for sale

- we sale barite for oil mpanies

- Bauxite Mining Process List Theabilitynet

- Screw Conveyor Design Handbook Free Download

- salt crusher machinery suppliers of india

- pengiriman motor ke makassar

- quartz separation processing equipment

- mining and crushing jigging machine

- internal grinding machine manufacturer in faridabad

- canada uranium minerals grinding mill

- DEWAN DIREKSI PT MANTIMIN COAL MINING

- 6061 6063 hot sale anodized sunflower aluminum heat sink

- GOLD DREDGING WITH SUCTION DREDGES

- rock crushers for sale in malaysia in kuala lumpur malaysia

- good price grinding mills wet grinding ball mill

- vertical rolling mill lochae

- select crushing equipment

- roasting of metal sulfides

- crushers spare parts sweden

- homemade rock crusher for sale

- startup procedure vibrating screen

- magnetic mining separation

- flow diagram for iron ore refinning

- vertical shaft crusher pcl

- energy saving 2016 hot sale new type stone impact crusher

- deepa stone crushers send hand

- quartz stone quarrying line sand making stone quarry

- al port expansion work programme expansion

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

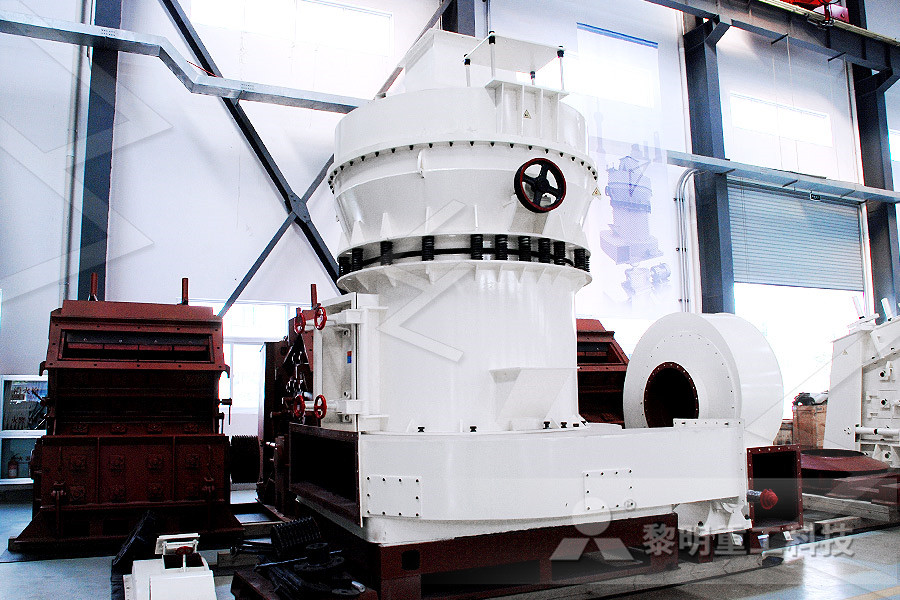

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine