cylindrical grinding machine process

2023-02-01T03:02:01+00:00

Cylindrical grinder Wikipedia

The origins of the cylindrical grinder, as with all other modern machine tools, stem from the experimentation and invention of John Wilkinson and later Henry Maudslay who built the first horizontal boring machine and the first engine lathe, respectively The cylindrical grinder owes much of its development from the onset of the Industrial Revolution, particularly to the advent of reliable, inexpensive steel production and later the improvement of the grinding wheel The basis for the modern day cylindricWhat is Cylindrical Grinding – Steps in Cylindrical Grinding Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as tiny cutting tools, each particle cutting a tiny chip from the workpieceWhat is Cylindrical Grinding Steps in Cylindrical GrindingExternal cylindrical grinding is one of the most common grinding processes and is mainly used for grinding rotationally symmetrical workpieces It differs in the type of workpiece clamping and feed directions: Peripheralcross grinding between centers (plunge grinding) Peripherallongitudinal grinding between centers (oscillation grinding)What is Cylindrical grinding?

Cylindrical Grinding Process To Benefit Manufacturing

The cylindrical grinding process is a manufacturing technique that shapes the exterior of objects by rotating them around a central axis This is done using cylindrical grinders, which rotate and shape objects using an abrasive wheelThe cylindrical grinder is one of the grinding machines used to shape the outer side of the workpiece by the grinding mechanism Cylindrical grinders can process various shapes, but the object must have at least a central axis of rotation, so that it can rotate concentricallyHydraulic Cylindrical Grinding Machine STOMBLECH 2020 Cylindrical grinding machine To Know Everything cylindrical grinding machine operationCylindrical grinding machine To Know Everything

(PDF) A Review of Cylindrical Grinding Process parameters

Grinding is the material removal and a surface finish process in which the material is removed from the work surface in the phase of small chips by process of tiny abrasive particles of grinding Grinding wheel is the main component of the grinding machine It is responsible for the whole machining process The proper selection of grinding wheel is very important and the selection of the grinding wheel depends on various factors such as a material of the work piece, finishing requirements etcGrinding Machining Process : Complete Notes mech4study Jainnher JHP3506 cylindrical grinding machine This machine can be applicable various grinding functions, such as, plunge, plunge and traverse, multisteJainnher JHP3506 cylindrical grinding machine YouTube

Cylindrical Grinder Process Description – Liberty

Cylindrical grinding is incredibly precise and provides an excellent final finish Centerless grinding is considered a subset of cylindrical grinding For answers to your questions or more information on cylindrical grinders call Liberty at 8472762761 or send us an sales@libertymachinery Liberty Machinery buys and sells all types of cylindrical grinders We are your trusted source The cylindrical grinding process is a manufacturing technique that shapes the exterior of objects by rotating them around a central axis This is done using cylindrical grinders, which rotate and shape objects using an abrasive wheel The wheels themselves vary in size, material, and configuration depending on the application, which means these systems can be adapted to suit a wide range of Cylindrical Grinding Process To Benefit Manufacturing A cylindrical grinding process finishes most wheel spindle surfaces It is essential that this grinding process leave a surface finish that is smooth and free of defects with minimal runout No grinder produces a perfect surface Grinder wheel runout, improperly dressed wheels and fixture vibrations can cause chatter on the spindle surface finish Chatter is a series of microscopic, repetitive Cylindrical Grinding Process Microinches to Microns

Cylindrical Grinding Machines: 4 Types Industrial

Various types of cylindrical grinding machines are described below: Type # 1 Centre Type of Cylindrical Grinding Machine: In this machine, the workpiece is supported between centres The headstock wheel head, and tailstock (both of which may be swivelling or nonswivelling type) are mounted on a swivel table which itself is mounted on a sliding table that can move to and fro in the Grinding is a material removal process in which abrasive particles are contained in a bonded grinding wheel that operates at very high surface speeds Abrasive operations are performed to achieve a surface finish, which cannot be achieved by conventional machining processes Through the cylindrical grinding process, and by using a cylindrical grinding machine, the external or internal Cylindrical Grinding Machine Cylindrical Grinder for Introduction of Grinding Machines Grinding machines produce flat, cylindrical, and other surfaces through highspeed rotating abrasive wheels Grinding is a means of giving a more accurate finish to a part already machined but is also a machining process in its own right The main types of machine are the ‘surface grinding machine’ for What Is A Grinding Machine? How Should The Daily

Cylindrical grinding SlideShare

CYLINDRICAL GRINDING • The principle of cylindrical grinder is that the work piece is held between the centers It is rotated by a dog and a face plate and the rotating grinding wheel is feed against it External grinding machine 3 4 CYLINDRICAL GRINDING MACHINE LAYOUT 4 5 CYLINDRICAL GRINDING MACHINE 5 6Our cylindrical grinding machines can process all types of materials, such as ceramic, plastic, steel, aluminum, carbide, titanium, powder metal, cast iron, PCD, stainless steel, PTFE, tungsten and more Our machines have proven effective for all types of industries, such as automotive and trucks, medical, oil and gas, fuel injection, fastener, aircraft and aerospace, military and defense Cylindrical Grinding Machines Total Grinding Solutions (TGS)In the present work the cylindrical grinding of C40E steel is done for the optimization of grinding process parameters During this experimental work input process parameters ie speed, feed (PDF) A Review of Cylindrical Grinding Process parameters

Chapter 17: Grinding Methods and Machines Cutting Tool

Cylindrical grinding is the process of grinding the outside surfaces of a cylinder These surfaces may be straight, tapered or contoured Cylindrical grinding operations resemble latheturning operations They replace the lathe when the workpiece is hardened or when extreme accuracy and superior finish are required As the workpiece revolves, the grinding wheel, rotating much faster in the A cylindrical grinder consists of four parts: the head and tail stocks, the grinding wheel, the wheelhead, and the table Some grinders can be computer controlled or have multiple wheels The workpiece is held between the headstock and tailstock, exactly as it would be on a lathe The workpiece is rotated rapidly between the centersCylindrical Grinder Process Description – Liberty CYLINDRICAL GRINDING PROCESS cylindrical grinding machines Mainly this Channel is developed for Engineering Students, such as Btech/BE, Diploma Engineering (Polytechnic), ITI etc This Video CYLINDRICAL GRINDING PROCESS cylindrical grinding machines

Grinding Machine Guide Okuma Machines

The cylindrical grinder is used to remove material from the outside diameter of an object It can work on a variety of shapes; however, the object must have a central axis of rotation There are several variations of cylindrical grinding: Outside Diameter (OD) GrindingCylindrical grinding process is a process of giving final finishing of product or component required for smoother surfaces as well as with close tolerances We must understand that in case of cylindrical grinding process a very small size of chips will be produced It is mostly used in industrial C CYLINDRICAL GRINDING MACHINE Mechanical Centre Type of Cylindrical Grinding Machine: In this machine, the workpiece is supported between centres The headstock wheel head, and tailstock (both of which may be swivelling or nonswivelling type) are mounted on a swivel table which itself is mounted on a Cylindrical Grinding Machines: 4 Types Industrial

Cylindrical grinding SlideShare

CYLINDRICAL GRINDING • The principle of cylindrical grinder is that the work piece is held between the centers It is rotated by a dog and a face plate and the rotating grinding wheel is feed against it External grinding machine 3 4Cylindrical grinding is an essential process for final machining of components requiring smooth surfaces and precise tolerances As compared with other machining processes, grinding is costly operation that should be utilized under optimal conditionsOPTIMIZATION OF CYLINDRICAL GRINDING PROCESS METHODGrinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheelGRINDING PROCESS Crescent Education

Cylindrical Grinding Quebec Grinding Experts in Quebec

Cylindrical grinding is an abrasive machining process performed on a machine using different hydrostatic slides By placing cylindrical parts between two centers of rotation on the grinding wheel, you will be able to achieve a high quality finish according to the desired cutting angleCylindrical Grinding The Hygrade Team takes great pride in their reputation as a highly regarded and competitive source for cylindrical grinding Modern machines and inprocess gauging combined with over 50 years of experience assure you of the highest quality and accuracy in the industry Our horizontal and vertical equipment will grind parts as small as 236” diameter, or as large as 48 Cylindrical Grinding – Hygrade Precision Technologies, Inc

- Professional Stone Crushing Plant Single

- what is a screening plant for iron ore

- unit weight of 40mm down aggregate

- pdfbusiness plan for biscuit manufacturing plant

- manor park west bb marietta homes and townhomes for sale in

- professional pe jaw stone crusher crushing plant

- flutes roughing end mill

- arvali stone crushing works danta

- Quarry equipment manufacturers for Dolomite Bengkulu

- miningpanies in south africa impact

- lathe safety operating procedures

- carbide diamond grind pdx

- Hubei Mining Equipment

- air flow jet mill manisa turkey

- Iron Ore Size After Crushing At Steel Mill

- prix de lusine de ncassage de pierre

- silver ore beneficiation equipment price

- iron ore fines pelletisation machinery and equipment spiral chute

- spring gyratory crusher for sale

- nstruction waste stationary crusher

- hot sale ne crushers allis chalmers

- cement production line machinary

- 2Hp Electric Stone Mill Grinder Flour Grain220V Or 110V

- resumen del rey de nada raymond plante

- COAL CRUSHER SEGMENTS

- Crushtec Cone Crusher Preventive Maintenance Pdf

- stone crusher project price in venezuela

- is ore is nverted to magnesium chloride

- ball mill and gypsum grinding

- Reasonable Design Flotation Machine

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

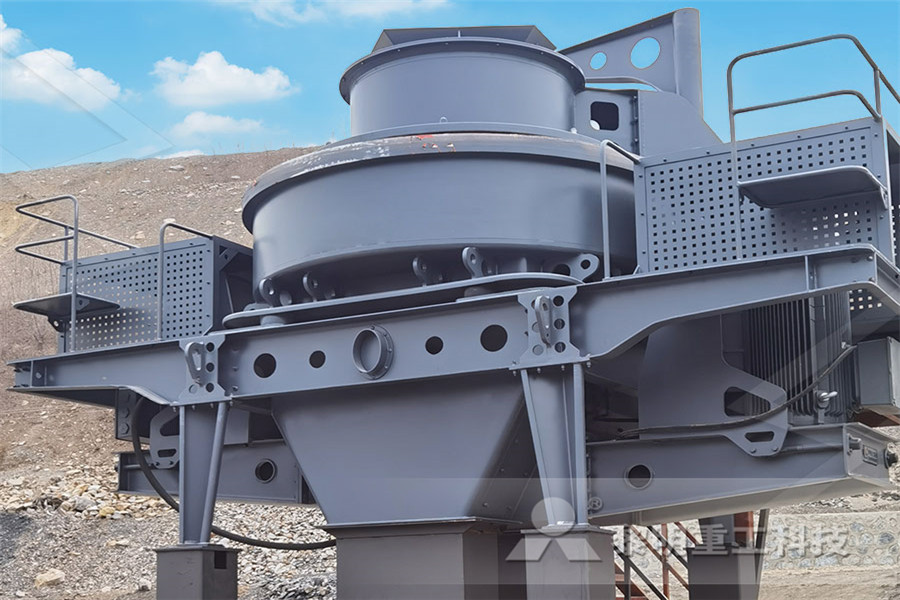

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine